DEMAG SERVO DRIVE

DEMAG SERVO DRIVE Specification

- Noise Level

- < 65 dB

- Working Temperature

- 0C to +55C

- Current Range

- 0.5 A to 15 A

- Power Factor

- >0.96

- Rated Current

- 12 A

- Phase

- Three Phase

- Features

- Integrated safety features, Compact design, High dynamic response

- Application

- Automated Industrial Machinery, Injection Molding Machines

- Power Supply

- AC Power Supply

- Operating Temperature

- 0C to +55C

- Rated Power

- 5.5 kW

- Output Type

- Three Phase AC

- Connector Type

- Screw Terminal / Plug-in

- Output Current

- 12 A

- Cooling Method

- Forced Air Cooling

- Product Type

- Servo Drive

- Output Power

- 5.5 kW

- Output Frequency

- 0 400 Hz

- Input Voltage

- 3 x 400 V AC

- Voltage Protection

- Overvoltage, Undervoltage

- Efficiency

- Up to 98%

- Material

- Aluminium/Steel Housing

- Line Regulation

- 0.1%

- Storage Temperature

- -20C to +70C

- Weight

- Approx. 6 kg

About DEMAG SERVO DRIVE

Optimum Plant Application & Competitive Advantages

The DEMAG SERVO DRIVE is expertly crafted for automated industrial machinery and injection molding machines, guaranteeing superior operational efficiency and reliability. Its compact, panel-mount design and high dynamic response provide outstanding versatility within plant settings. Key features such as integrated safety, robust aluminium/steel housing, and dynamic braking set it apart from competitors. Additionally, its EMC compliance, forced air cooling, and precise LED/LCD displays enhance performance and user confidence in mission-critical applications.

Sample Policy, Delivery, and Certifications

Experience our transparent DEMAG SERVO DRIVE Sample Policy, tailored for seamless export market engagement. Units are typically dispatched swiftly following order valuation and confirmation. Delivery timelines are configured to align with client schedules, ensuring reliability and efficiency. The product arrives with comprehensive certification, reflecting adherence to EN 61800-3 standards and quality benchmarks. Rest assured, each DEMAG SERVO DRIVE is curated to meet international norms, delivering the assurance modern industries demand.

FAQs of DEMAG SERVO DRIVE:

Q: How does the DEMAG SERVO DRIVE enhance industrial automation processes?

A: By integrating advanced vector and servo control methods with high response speeds and dynamic braking circuits, the DEMAG SERVO DRIVE delivers precise, responsive control essential for automated machinery and injection molding applications.Q: What are the primary benefits of the integrated safety features and dynamic braking?

A: The integrated safety features safeguard equipment and operators, while the dynamic braking circuit ensures rapid, controlled decelerationminimizing downtime and boosting operational reliability.Q: Where can the DEMAG SERVO DRIVE be mounted and what environments is it suitable for?

A: Designed for panel mounting, the DEMAG SERVO DRIVE is suitable for industrial environments with temperatures ranging from 0C to 55C and humidity below 90% (non-condensing), making it ideal for various plant settings.Q: What types of motors and communication interfaces are supported?

A: The DEMAG SERVO DRIVE supports AC servo and synchronous motors, and is compatible with CANopen, Profibus, and optional EtherCAT communication for flexible system integration.Q: How efficient is the DEMAG SERVO DRIVE and what certifications does it hold?

A: Achieving up to 98% efficiency, the DEMAG SERVO DRIVE is EMC-compliant (EN 61800-3), meeting stringent safety and performance standards for global industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DEMAG SERVO DRIVE Category

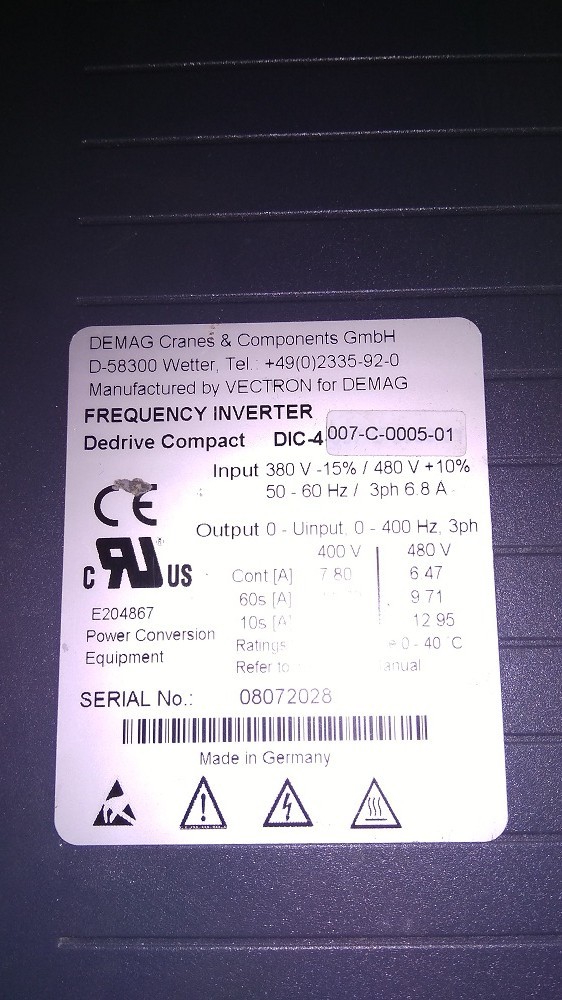

DEMAG DIC-4-002-C-0003-01 FREQUENCY INVERTER DRIVES

Minimum Order Quantity : 1 Piece

Input Voltage : 400 V AC

Application : Hoist and Crane Automation, Motor Speed Control, Industrial Automation

Power Supply : ThreePhase AC

Features : LED Status Indication, Compact Design, Microprocessor Controlled

Phase : Three Phase

DEMAG DIC-4-002-C-0001-01 FREQUENCY INVERTER DRIVE

Minimum Order Quantity : 1 Piece

Input Voltage : 380480 V AC

Application : Industrial Automation, Crane Operations, Conveyor Drive Control

Power Supply : 3Phase 380480 V AC, 50/60 Hz

Features : Digital Display, Programmable Settings, Soft Start, Protection Features

Phase : Three Phase

DEMAG SERVO DRIVE

Input Voltage : 3Phase 400V AC

Application : Industrial automation, Injection molding machines

Power Supply : AC 400V 50/60 Hz

Features : Compact design, Digital display, High reliability, Energy efficiency

Phase : Three Phase

DEMAG SERVO DRIVE

Input Voltage : 380480 V AC

Application : Injection Molding Machines, Automation, Motion Control

Power Supply : AC

Features : Compact Design, High Accuracy, Easy Installation, Advanced Diagnostics

Phase : Three Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry