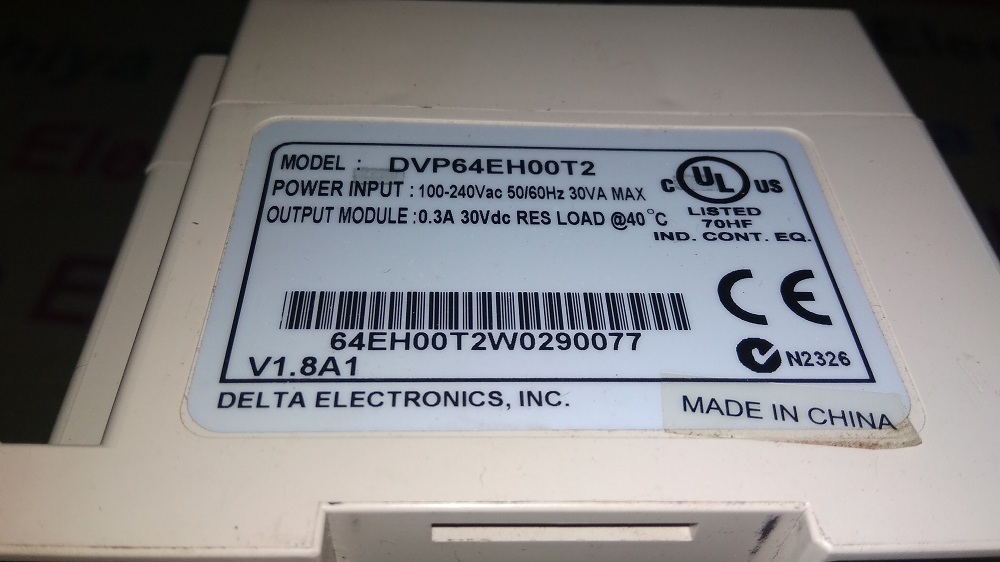

DELTA PLC

DELTA PLC Specification

- Operating Temperature

- 0C to 55C

- Application

- Industrial Automation, Machinery Control, Process Control

- Noise Level

- <45 dB

- Features

- Small size, Easy programming, High reliability, Modbus support

- Rated Current

- 0.5A

- Output Type

- Relay/Transistor

- Power Supply

- 24V DC

- Working Temperature

- 0C to 55C

- Rated Power

- 12W

- Phase

- Single Phase

- Power Factor

- >0.95

- Connector Type

- Screw Terminals

- Output Current

- 0.5A

- Cooling Method

- Natural air cooling

- Current Range

- 0.1A to 0.5A

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- 24VDC, 0.5A

- Output Frequency

- 50/60 Hz

- Input Voltage

- 24V DC (+20%, -15%)

- Voltage Protection

- Yes (Over-voltage/Under-voltage)

- Efficiency

- Above 80%

- Material

- Plastic Body with Metal Mounting

- Line Regulation

- 1%

- Storage Temperature

- -20C to 70C

- Weight

- Approx. 300g

- Response Time

- <0.5 ms

- Display Type

- LED Indication

- Memory Capacity

- 8K Steps

- Digital Outputs

- 6 Channels

- Expansion Capability

- Supports Expansion Modules

- Communications Port

- RS-232/RS-485

- Digital Inputs

- 8 Channels

- Programming Software

- Delta WPLSoft

- Mounting Type

- DIN Rail Mounting

- Protection Level

- IP20

About DELTA PLC

Features, Usage & Applications of DELTA PLC

This small-sized DELTA PLC impresses with its high reliability, LED indication, and advanced Modbus support. Designed for easy programming, it excels in industrial automation, machinery control, and process management scenarios. Its flexible usage type includes application in both standalone and integrated system configurations, ensuring exceptional versatility. The robust plastic body with metal mounting and natural air cooling enhance durability and operational stability, while the screw terminal connectors simplify installation and maintenance for users in diverse environments.

DELTA PLC Payment Terms & Supply Overview

We offer a premium, customer-friendly procurement process with transparent payment terms and estimated delivery schedules tailored to your requirements. Sample units are available for evaluation before large exchanges, ensuring confidence in your investment. With an assured high supply ability, partners and traders across India benefit from reliable dispatch and ongoing product support. Experience seamless ordering, prompt response, and dependable nationwide distribution of this feature-rich technology solution for all your automation needs.

FAQs of DELTA PLC:

Q: How does the DELTA PLC support expansion capabilities for various applications?

A: The DELTA PLC is designed to support expansion modules, allowing users to scale input and output channels, adapt to evolving process demands, and customize for a broad range of industrial and machinery control scenarios.Q: What programming software is used for the DELTA PLC and is it user-friendly?

A: DELTA PLC utilizes Delta WPLSoft, an intuitive and robust programming software that simplifies the process of configuring logic, routines, and communication parameters for both new and experienced users.Q: When is the best time to request a sample unit of the DELTA PLC?

A: You can request a sample unit at any stage prior to bulk purchase, which is recommended during the assessment phase to evaluate product fit and performance within your specific automation or machinery setup.Q: What is the step-by-step process for integrating DELTA PLC into existing systems?

A: Integration involves mounting the PLC with the DIN rail bracket, connecting modules using screw terminals, configuring inputs/outputs via WPLSoft, and establishing communication through RS-232/RS-485 ports, followed by system testing for seamless operation.Q: Where can the DELTA PLC be effectively used within industrial environments?

A: The DELTA PLC is ideal for applications such as industrial automation, machinery control, and process management, ensuring optimal performance in factories, workshops, and automated production lines.Q: What are the key usage benefits of the DELTA PLC for suppliers and traders?

A: Suppliers and traders benefit from the PLCs competitive pricing, high reliability, easy programming, and strong supply ability, along with the confidence of robust protection features and nationwide delivery support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DELTA Used PLC HMI AC DRIVE Category

MITSUBISHI HMI

Cooling Method : Natural Air Cooling

Product Type : Mitsubishi Human Machine Interface (HMI)

Connector Type : Screw Terminal, USB TypeA/B, Ethernet (RJ45)

Phase : Single Phase

Efficiency : Typ. 85%

Working Temperature : 0C to +50C

Delta VFD004L21A

Cooling Method : Natural cooling

Product Type : Variable Frequency Drive (VFD)

Connector Type : Terminal block

Phase : Other, Singlephase input threephase output

Efficiency : High efficiency

Working Temperature : 10C to 50C

DELTA POWER SUPPLY DELTA 77-964-4300

Cooling Method : Aircooled

Product Type : Power Supply Unit

Connector Type : Standard Connectors

Phase : Other, Singlephase

Efficiency : High Efficiency

Working Temperature : 0C to 40C

DELTA KJ1501X1-BA2 POWER SUPPLY

Cooling Method : Natural Air Cooling

Product Type : Power Supply Unit

Connector Type : Screw Terminal Block

Phase : Single Phase

Efficiency : >88% (typical at full load)

Working Temperature : 20C to +70C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry