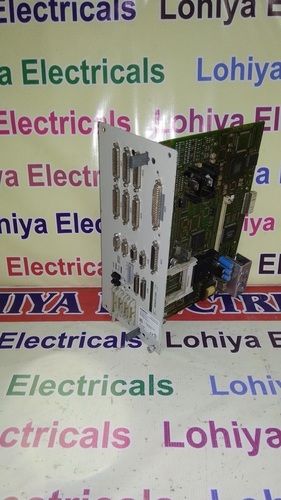

CONTROL SYSTEM SINUMERIK

CONTROL SYSTEM SINUMERIK Specification

- Features

- User-Friendly Interface, Real-Time Monitoring, High-Speed Processing, Integrated Safety Functions

- Phase

- Single Phase

- Frequency

- 50/60 Hz

- IP Rating

- IP65 (Front)

- Connectivity Type

- Ethernet, USB, RS232, Profibus, Profinet

- Current

- Max 2.5 A

- Usage & Applications

- Precision CNC Machining, Automation Systems, Robotics

- Display

- Color LCD Display, 15 (Standard), Touchscreen Optional

- Protection Level

- IP65 (Front Panel)

- Output

- Digital / Analog

- Switch Type

- Membrane / Touch Keys

- Mounting Type

- Panel Mount / Flush Mount

- Installation Type

- Panel Mount or Cabinet Mount

- Product Type

- CNC Control System

- Operating Temperature

- 0C to +55C

- Working Temperature

- 0C to +55C

- Input

- Digital / Analog

- Application

- Industrial Automation, CNC Machines, Manufacturing

- Supply Voltage

- 24 V DC (Main), 230 V AC (Power supply)

- Accuracy

- High Precision Positioning (Typically 0.001 mm)

- Dimension (L*W*H)

- Varies by Model (e.g., 450mm x 350mm x 150mm)

- Weight

- Approx. 8-11 kg (Depending on Version)

- Data Storage

- Onboard memory, Expandable via USB/CF Card

- Ambient Humidity

- 5% - 95% (non-condensing)

- System Platform

- SINUMERIK 808D/828D/840D SL (depending on model)

- Remote Diagnostics

- Supported via Ethernet

- Cooling

- Built-in Fan Cooling System

- Supported Axes

- Up to 93 NC axes, 31 machining channels

- Programming Language

- DIN/ISO, ShopMill, ShopTurn, G-code

- Safety Functions

- Integrated Emergency Stop, Safe Torque Off (STO)

- Integrated PLC

- Siemens S7-200/300/ integrated

About CONTROL SYSTEM SINUMERIK

Applications and Versatility Across Industries

CONTROL SYSTEM SINUMERIK has been engineered for use in high-precision CNC machining, industrial automation systems, and robotics. Whether controlling complex manufacturing lines or individual CNC machines, this system excels in rigorous environments. Its application media include cutting-edge manufacturing plants and automated production units, where uncompromising accuracy and robust reliability are paramount. Ideal for enterprises seeking to optimize performance across numerous industrial sectors where dependable and flexible control solutions are valued.

Sample Availability, Supply, and Market Value

Sample units of CONTROL SYSTEM SINUMERIK are available for dispatching to serious buyers, ensuring you can test its capabilities before investing. Favorable payment terms accommodate diverse business needs, while our supply ability meets market value demands throughout India. Sale prices are competitive, reflecting the products advanced features, reliability, and adaptability. Secure your order now and be part of the select group benefiting from streamlined installation and rapid delivery for mission-critical automation projects.

FAQs of CONTROL SYSTEM SINUMERIK:

Q: How does the CONTROL SYSTEM SINUMERIK enhance industrial automation processes?

A: The CONTROL SYSTEM SINUMERIK provides high-speed processing, real-time monitoring, and robust safety functions, enabling precise and efficient control of CNC machines and industrial automation systems.Q: What types of axes and channels can the CONTROL SYSTEM SINUMERIK support?

A: Depending on the model, the system can manage up to 93 NC axes and 31 machining channels, offering extensive flexibility for complex manufacturing setups.Q: When should I consider using the CONTROL SYSTEM SINUMERIK for my facility?

A: You should consider this system when aiming to achieve high-precision positioning, integrated safety, and advanced connectivity in applications such as CNC machining, automation, and robotics.Q: Where can the CONTROL SYSTEM SINUMERIK be installed?

A: The system supports both panel and cabinet mounting, making it suitable for a variety of industrial setups in manufacturing environments.Q: What benefits does the CONTROL SYSTEM SINUMERIK offer in terms of connectivity and data management?

A: With Ethernet, USB, RS232, Profibus, and Profinet connectivity, along with onboard and expandable data storage, users enjoy seamless integration, remote diagnostics, and versatile data management capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEMENS CONTROL BLOCK Category

SIEMENS CONTROLBLOCK

Working Temperature : 10C to +60C

Supply Voltage : 24V DC / 230V AC

Switch Type : Electronic/Mechanical

Output : Relay/Transistor outputs

Protection Level : Other, Overload, Short circuit protection

Installation Type : Panel Mount

SIEMENS S120 POWER BORD

Working Temperature : 0C to +40C

Supply Voltage : DC 24V or AC 230V

Switch Type : Electronic

Output : DC Output

Protection Level : Other, Overload, Short Circuit, Overvoltage

Installation Type : Panel Mount

SIEMENS SINUMERIK 840/DE

Working Temperature : 0C to +55C

Supply Voltage : 230 V AC (Power Supply)

Switch Type : Electronic Switches

Output : Digital/analog outputs

Protection Level : Other, Overvoltage, Short Circuit Protection

Installation Type : Panel/Horizontal Mount

CONTROL BLOCK

Working Temperature : 10C to +60C

Supply Voltage : 24V DC

Switch Type : Push Button/Rotary

Output : Relay/Signal Output

Protection Level : IP65

Installation Type : Panel Mounted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry