CONTROL SYSTEM SINUMERIK

CONTROL SYSTEM SINUMERIK Specification

- Output

- Digital/Analog Outputs based on configuration

- Switch Type

- Membrane / Tactile Switches (dependent on HMI)

- Usage & Applications

- CNC Machines, Lathes, Milling, Industrial Automation

- Frequency

- 50/60 Hz

- Mounting Type

- Control Panel Mounting

- Installation Type

- Panel-mounted

- Current

- Rated as per model

- Connectivity Type

- Ethernet, Profibus, USB, RS232/RS422

- Phase

- Single/Three phase options

- Measuring Range

- Depends on sensor integration

- Display

- Color TFT LCD Display

- Sensor Type

- Supports multiple sensor interfacing

- Protection Level

- Over-voltage & Over-current Protection

- Features

- High speed processor, Multitasking, User-friendly interface, Real-time control

- IP Rating

- IP20 (control cabinet)

- Product Type

- CNC Control System

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0C to 55C

- Input

- Digital/Analog Inputs depending on configuration

- Application

- Industrial Automation, CNC Machines, Robotics

- Supply Voltage

- 24 V DC (logic), 230 V AC (power)

- Accuracy

- High precision control (subject to configuration)

- Dimension (L*W*H)

- Varies per system, typical: 600mm x 450mm x 200mm

- Weight

- Approx. 20-30 kg depending on configuration

- Graphic Display Size

- 10.4"/15"/19" LCD (depending on variant)

- Cooling Method

- Integrated fan, optional air conditioning

- Remote Diagnostics

- Supported via Ethernet

- Programming Language

- G-code, Siemens high-level CNC language support

- Compliance

- CE, UL, and international standards

- Supported Control Models

- SINUMERIK 808D, 828D, 840D, and others

- Expandability

- Modular hardware and software architecture

- Firmware Update

- Via USB/Ethernet

- Control Axis Capability

- Up to 31 axes, 10 spindles (varies per model)

- Data Logging

- Yes, with trace and diagnostics

- Software Platform

- SINUMERIK Operate (user interface)

- Ambient Humidity

- Max. 90% RH, non-condensing

About CONTROL SYSTEM SINUMERIK

Preferred by Industry Leaders Across Multiple Sectors

CONTROL SYSTEM SINUMERIK is widely used by engineers, machinists, and manufacturers for high-performance CNC machines, lathes, milling, and comprehensive industrial automation. The usage type encompasses both standalone machines and integrated production lines. Key features include high-speed processing, real-time multitasking, user-friendly graphical displays, and robust sensor compatibility. Trusted by top-tier professionals, its noble reliability ensures operational excellence in advanced robotics and precision fabrication environments, supported by flexible panel-mount installation and compliance with global standards.

Reliable Supply and Flexible Delivery Options Worldwide

CONTROL SYSTEM SINUMERIK is backed by a robust supply ability, ensuring prompt availability for both small and bulk orders. Goods are securely packaged and delivered through trusted transport services, with special arrangements for international shipments to key export markets in Europe, Asia, and the Americas. Sample policy options are available on request, assisting clients to assess system compatibility before full-scale deployment. Comprehensive logistics support makes receiving this product seamless for global customers, maximizing satisfaction and productivity.

FAQs of CONTROL SYSTEM SINUMERIK:

Q: How does CONTROL SYSTEM SINUMERIK enhance industrial automation processes?

A: CONTROL SYSTEM SINUMERIK provides real-time, high-precision control of up to 31 axes and 10 spindles, enabling advanced multitasking and sophisticated automation for various applications in CNC machines, robotics, and manufacturing lines.Q: What models of SINUMERIK are supported by this control system?

A: This system supports multiple SINUMERIK control models, including the 808D, 828D, 840D, and other compatible variants, accommodating diverse operational needs in industrial environments.Q: Where can the CONTROL SYSTEM SINUMERIK be installed?

A: The system is designed for panel-mounted installation within industrial control panels, providing flexibility and secure integration into existing production or automation infrastructure.Q: What type of connectivity does CONTROL SYSTEM SINUMERIK offer for data and diagnostics?

A: Connectivity options include Ethernet, Profibus, USB, and RS232/RS422, facilitating remote diagnostics, firmware updates, and communication with external devices and networks.Q: What are the main benefits of using CONTROL SYSTEM SINUMERIK in CNC applications?

A: Benefits include its user-friendly graphical interface, modular expandability, compliance with CE and UL standards, high-speed processing, robust protection features, and support for complex programming via G-code and Siemens CNC language.Q: When is the optimal working temperature for this control system?

A: The optimal operating and working temperature range is from 0C to 55C, making it suitable for various industrial environments with controlled ambient conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEMENS CONTROL BLOCK Category

SIEMENS CONTROL BLOCK

Features : Long Mechanical Life, Reliable Operation, Quick Installation

Weight : Approx. 100g

Operating Temperature : 25C to +70C

IP Rating : IP20

Protection Level : Other, IP20

Supply Voltage : 24V/48V/110V/230V AC/DC

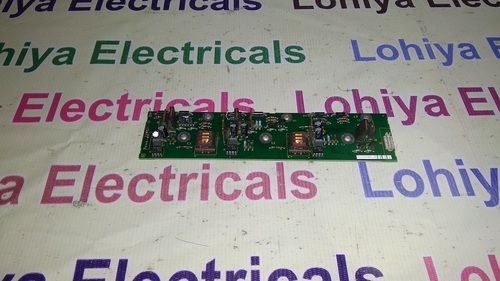

SIEMENS POWER BORD

Features : Shock resistance, flame retardant, modular construction

Weight : Approx. 2.5 kg

Operating Temperature : 10C to +50C

IP Rating : IP44

Protection Level : Other, IP44

Supply Voltage : 230V AC

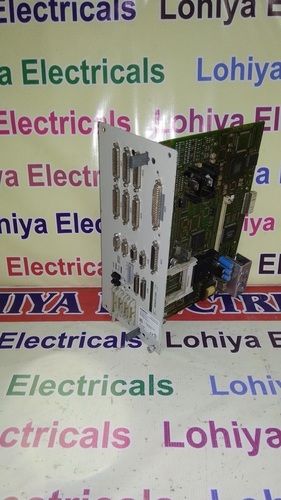

SIEMENS SINUMERIK 840/DE

Features : Multichannel architecture, scalable, integrated PLC, userfriendly interface, highspeed processing

Weight : Approx. 12 kg

Operating Temperature : 0C to +55C

IP Rating : IP20

Protection Level : Other, Overvoltage, Short Circuit Protection

Supply Voltage : 230 V AC (Power Supply)

SIEMENS SINUMERIK 840/DE

Features : Userfriendly interface, highspeed CPU, integrated diagnostics, modular expandability

Weight : Approx. 20 kg (may vary)

Operating Temperature : 0C to +55C

IP Rating : IP20

Protection Level : Other, IP20

Supply Voltage : 24V DC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry