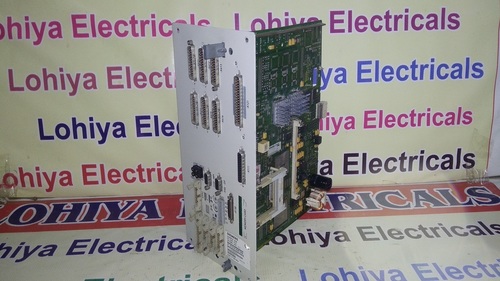

CONTROL SYSTEM SINUMERIK

CONTROL SYSTEM SINUMERIK Specification

- Current

- Maximum 5A

- Usage & Applications

- Industries, CNC Machines, Production Lines

- Protection Level

- IP20/IP65 (Front panel)

- IP Rating

- IP20/IP65

- Frequency

- 50/60 Hz

- Display

- 10.4-inch TFT Color Display

- Phase

- Single Phase / Three Phase

- Switch Type

- Electronic Switches

- Installation Type

- Panel Mounted

- Connectivity Type

- Ethernet, Profibus, USB

- Features

- High reliability, Advanced programming, User-friendly interface

- Mounting Type

- Flush Mount

- Output

- Digital/Analog Outputs, 24V DC

- Product Type

- CNC Control System

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0C to 55C

- Input

- 24V DC (standard), Digital/Analog Inputs

- Application

- CNC Machine Tools, Automation Systems

- Supply Voltage

- 230V AC/24V DC

- Accuracy

- 0.01mm

- Dimension (L*W*H)

- Varies by model, e.g., 400mm x 300mm x 150mm

- Weight

- Approx. 10 kg

- Backup Options

- USB/CF Card/Data Server

- Axes Supported

- Up to 31 axes (model dependent)

- Response Time

- <1ms (cycle time)

- Power Consumption

- Max. 175W

- Supported Interfaces

- RS232, Profinet, Ethernet, USB

- Diagnostic Functions

- Integrated self-diagnostics, Remote maintenance

- Control System

- Siemens SINUMERIK Series

- Cooling Method

- Air cooled

- Memory Capacity

- 1GB RAM (expandable), 10GB Storage

- Programming Languages

- G-code, Siemens ShopMill/ShopTurn, ISO dialect

About CONTROL SYSTEM SINUMERIK

Versatile Solutions for Every Application

The CONTROL SYSTEM SINUMERIK thrives across diverse application surfaces such as CNC machine tools, production lines, and automation systems. Its key advantage lies in supporting up to 31 axes (model dependent), delivering advanced programming with a user-friendly interface. Installation is straightforward through panel or flush mounting, enabling seamless integration into both new and existing industry frameworks. With precision accuracy (0.01mm), air-cooled operation, and robust connectivity, it streamlines processes for manufacturers seeking smarter, more reliable automation.

Flexible Payment, Convenient Shipping, and Sampling Options

Managing your expenditure is made simple with flexible payment terms tailored to your needs. The CONTROL SYSTEM SINUMERIK is shipped via reliable FOB ports, ensuring prompt arrival and smooth logistics. Our transparent sample policy reduces the upfront charge, allowing you to evaluate product performance before a full-scale investment. These arrangements help streamline your acquisition process, making it easier and cost-effective to integrate this advanced control system into your workflow.

FAQs of CONTROL SYSTEM SINUMERIK:

Q: How can I integrate the SINUMERIK control system into my existing CNC machines?

A: The SINUMERIK system is panel or flush mounted and supports industrial-standard interfaces like RS232, Profinet, and Ethernet, enabling straightforward integration with a wide range of CNC machines and automation systems.Q: What are the benefits of the systems diagnostic functions?

A: Integrated self-diagnostics and remote maintenance capabilities allow for quick issue identification, minimizing downtime and ensuring uninterrupted production for maximum reliability.Q: What applications is the CONTROL SYSTEM SINUMERIK best suited for?

A: This system excels in CNC machine tools, automation systems, and production lines, offering high reliability, accuracy, and multi-axis control for manufacturing and industrial operations.Q: When should I consider expanding the systems memory capacity?

A: Expand the memory capacity as your application complexity grows, or when you require more data storage and faster processing for intricate, multi-axis machining tasks.Q: What is the process for obtaining a sample of the SINUMERIK system?

A: Contact your supplier or trader directly to inquire about the sample policy. You can often secure a sample with a reduced upfront charge, allowing for practical evaluation before committing to a full order.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEMENS CONTROL BLOCK Category

SIMENS CONTROL BLOCK

Current : 10A

Usage & Applications : Control panels, industrial machinery, automation circuits

Operating Temperature : 25C to +70C

Supply Voltage : 24V DC / 230V AC

IP Rating : IP20

Frequency : 50/60 Hz

SIEMENS SINUMERIK 840/DE

Current : Rated up to 1.5A (Depending on module)

Usage & Applications : CNC Milling, Turning, Grinding, Machining Centers

Operating Temperature : 0C to 50C

Supply Voltage : 24V DC (typical for modules)

IP Rating : IP20

Frequency : 50/60 Hz

SIEMENS SINUMERIK 840/DE

Current : Depends on configuration

Usage & Applications : CNC Machining, Metal Cutting, Industrial Automation

Operating Temperature : 0C to +55C

Supply Voltage : 24 V DC (logic), 230 V AC (power)

IP Rating : IP20

Frequency : 50/60 Hz

SIEMENS SINUMERIK 840/DE

Current : Max. 2.5A

Usage & Applications : CNC, robotics, automation systems

Operating Temperature : 0C to +55C

Supply Voltage : 24V DC, 230V AC (control power)

IP Rating : IP20

Frequency : 50/60 Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry