CLIPSAL PLC

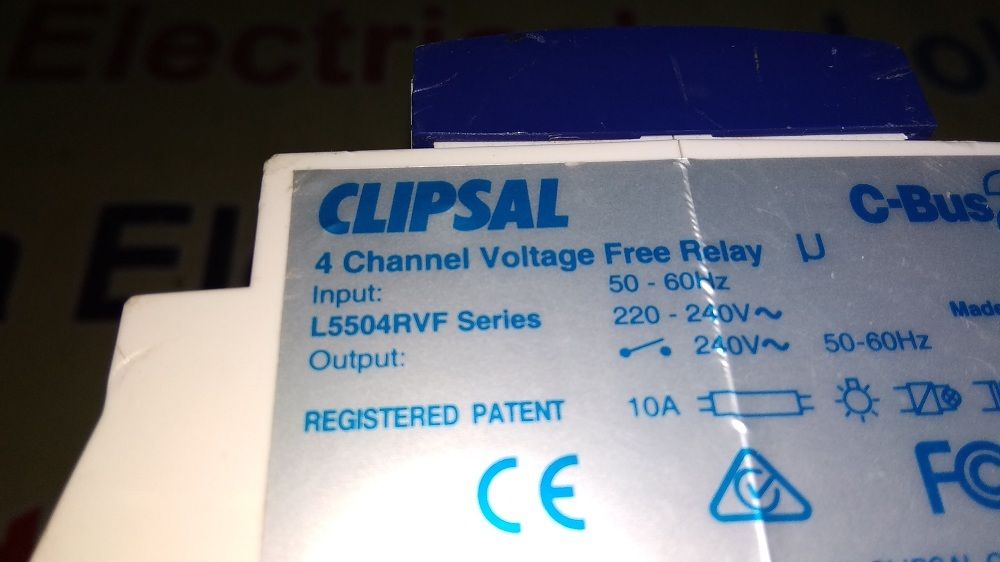

CLIPSAL PLC Specification

- Current Rating

- 10A

- Panel Type

- Control Panel Mounted

- Control System

- Relay/Transistor Output

- Rated Insulation Voltage

- 500V AC

- Base Material

- Polycarbonate

- Protection Level

- IP65

- Rated Operation Voltage

- 220V AC

- Rated Current

- 10A

- Components

- CPU, Input/Output Modules, Communication Ports

- Protection Class

- Class II

- Connectivity Type

- RS-232, RS-485, Ethernet

- Cooling System

- Natural Air Cooling

- Thickness

- 83 mm

- Operating Voltage

- 220-240V AC

- Way

- Multiple Input/Output Channels

- Cabinet Material

- Plastic

- Cover Material

- ABS Plastic

- Features

- Compact Size, Fast Response, Easy Installation

- Product Type

- Programmable Logic Controller (PLC)

- Material

- Polycarbonate and ABS Plastic

- Surface Finish

- Matte

- Standard

- IEC 61131-2

- Surface Color

- Grey

- Rated Voltage

- 220-240V AC

- Frequency (MHz)

- 50-60

- Maximum Output Current

- 10A

- Dimension (L*W*H)

- 150 x 90 x 83 mm

- Application

- Automation Control Systems

- IP Rating

- IP65

- Display Type

- LED Status Indication

- Relative Humidity

- 5% - 95% non-condensing

- Operating Temperature Range

- -10°C to +55°C

- Mounting Type

- DIN Rail Mount

- Response Time

- <1 ms

- Input Type

- Digital Inputs and Outputs

- Number of Outputs

- 8 Digital Outputs

- Storage Temperature Range

- -20°C to +70°C

- Programming Language

- Ladder Logic, Function Block Diagram

- Power Consumption

- <10 W

- Number of Inputs

- 12 Digital Inputs

About CLIPSAL PLC

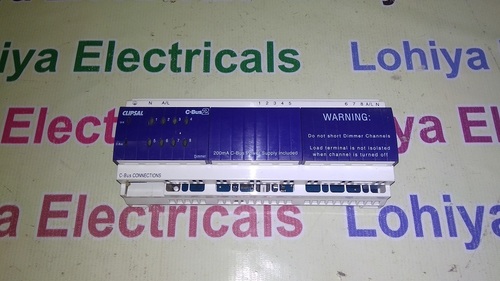

Discover the CLIPSAL PLC, a hot-selling paragon in automation control systems renowned for championing value and reliability. Designed for instant checkout, this classic PLC offers 12 digital inputs and 8 outputs, supporting versatile automation tasks. With DIN rail mounting and robust polycarbonate/ABS construction, it guarantees durability. Fast response times (<1 ms), advanced connectivity (RS-232, RS-485, Ethernet), and standards-aligned performance (IEC 61131-2) make it a trusted choice. Experience seamless installation, IP65 protection, 10A current rating, and ladder logic programming for optimal control.

Versatile Usage and Ideal Applications

CLIPSAL PLC, a classic champion for DIN rail mounting, is suitable for control panel automation and relay/transistor output systems. Its robust design makes it ideal for industrial plants, manufacturing lines, and process automation in building management. With multiple digital inputs/outputs and a compact profile, this PLC fits perfectly into tight spaces where reliable, fast-response automation is required. The mounting versatility ensures easy adaptation for both new installations and retrofit projects in diverse automation environments.

Certifications, Supply Capacity, and Packaging Excellence

CLIPSAL PLC meets key IEC 61131-2 standards, cementing its domestic market value and global trust. Available at the lowest price for suppliers and traders, it offers reliable supply ability to meet bulk demands, maintaining steady market value. Careful packaging ensures product integrity during shipping, protecting against damage. Whether for local use or widespread distribution, packaging details align with international norms, solidifying the products appeal in both domestic and export markets.

Versatile Usage and Ideal Applications

CLIPSAL PLC, a classic champion for DIN rail mounting, is suitable for control panel automation and relay/transistor output systems. Its robust design makes it ideal for industrial plants, manufacturing lines, and process automation in building management. With multiple digital inputs/outputs and a compact profile, this PLC fits perfectly into tight spaces where reliable, fast-response automation is required. The mounting versatility ensures easy adaptation for both new installations and retrofit projects in diverse automation environments.

Certifications, Supply Capacity, and Packaging Excellence

CLIPSAL PLC meets key IEC 61131-2 standards, cementing its domestic market value and global trust. Available at the lowest price for suppliers and traders, it offers reliable supply ability to meet bulk demands, maintaining steady market value. Careful packaging ensures product integrity during shipping, protecting against damage. Whether for local use or widespread distribution, packaging details align with international norms, solidifying the products appeal in both domestic and export markets.

FAQs of CLIPSAL PLC:

Q: How do I install the CLIPSAL PLC on a DIN rail?

A: Simply position the PLC against the DIN rail and snap it into place securely; the compact design and mounting mechanism ensure a fast, easy installation process.Q: What application areas are ideal for CLIPSAL PLC usage?

A: CLIPSAL PLC is ideal for automation control systems in industrial plants, manufacturing facilities, and building management, especially where multiple input/output channels and rapid response are needed.Q: When is ladder logic or function block diagram programming used with CLIPSAL PLC?

A: You should use ladder logic or function block diagram programming when customizing control operations, automating processes, or integrating the PLC with existing systems to achieve precise automation tasks.Q: Where is the best place to deploy the CLIPSAL PLC for maximum benefit?

A: Deploy the CLIPSAL PLC in locations requiring reliable automation and robust protectionsuch as control panels in high-demand, humidity-prone environmentsgiven its IP65 rating and wide operating temperature range.Q: What are the benefits of the LED status indication feature?

A: The LED status indication provides real-time operational feedback, allowing users to quickly identify system status, troubleshoot issues, and ensure optimal performance during ongoing operations.Q: How does the CLIPSAL PLC ensure safety and longevity in harsh environments?

A: Designed with IP65 protection, robust polycarbonate and ABS materials, and a wide temperature range, CLIPSAL PLC maintains safe and long-lasting operation even in demanding industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CLIPSAL MODULE CPU POWER SUPPLY HMI Category

CLIPSAL PLC

Standard : IEC/EN 611312

Panel Type : Wall Mount

Current Rating : 10 A

Maximum Output Current : 10A

Rated Current : 10 A

Rated Operation Voltage : 230V AC

CLIPSAL PLC

Standard : IEC 611312

Panel Type : Modular

Current Rating : 10A

Maximum Output Current : 10A

Rated Current : 10A

Rated Operation Voltage : 220V

CLIPSAL PLC

Standard : IEC 611312

Panel Type : Surface Mounted

Current Rating : 2A

Maximum Output Current : 2A

Rated Current : 2A

Rated Operation Voltage : 220V AC

CLIPSAL MODULE

Standard : IS/IEC 606691

Panel Type : Modular

Current Rating : 6A / 10A / 16A

Maximum Output Current : 16A

Rated Current : 6A / 10A / 16A

Rated Operation Voltage : 240V AC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry