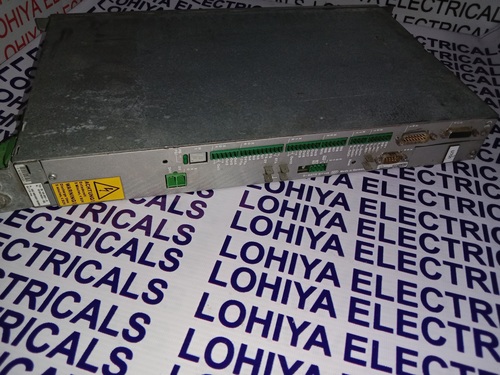

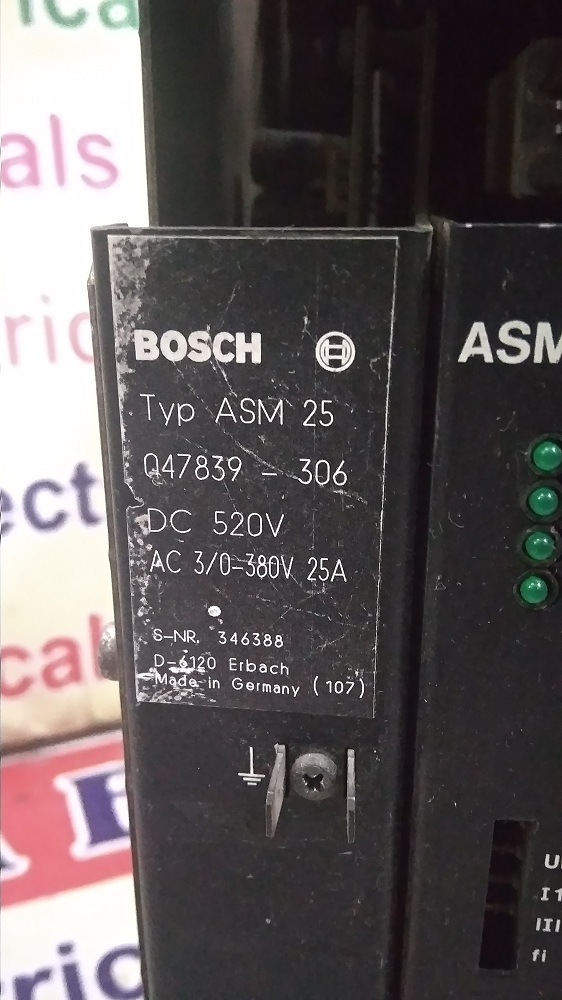

BOSCH SERVO DRIVE

BOSCH SERVO DRIVE Specification

- Cooling Method

- Forced air cooling

- Rated Current

- 3.5 A

- Noise Level

- <60 dB

- Power Factor

- >0.98

- Working Temperature

- 0C to 55C

- Operating Temperature

- 0C to 55C

- Rated Power

- 750 W

- Current Range

- 0~10 A

- Application

- Industrial automation, CNC machinery, robotics

- Features

- Compact structure, easy installation, precise control, energy saving

- Phase

- Single/Three Phase

- Output Current

- 3.5 A

- Output Type

- Digital

- Connector Type

- Industrial screw terminal

- Power Supply

- AC

- Product Type

- BOSCH SERVO DRIVE

- Output Power

- 750 W

- Output Frequency

- 0~650 Hz

- Input Voltage

- 200-240 V AC

- Voltage Protection

- Over and Under Voltage Protection

- Efficiency

- Greater than 90%

- Material

- High grade metal and electronic components

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 1.5 kg

- Pulse Input

- Maximum 500 kHz

- Relative Humidity

- Less than 90%, non-condensing

- Acceleration/Deceleration Time

- 0.01~6000 s

- Vibration Resistance

- 0.6G

- Control Method

- Vector Control, V/F Control

- Mounting Type

- Panel Mount

- Position Feedback

- Encoder Supported

- Communication Interface

- RS232/RS485, CANopen

- Response Time

- 2 ms

- Insulation Resistance

- >20M, 500VDC

- Display

- LED/LCD Digital Display

- Protection Rating

- IP20

- Altitude

- Up to 1000m without derating

About BOSCH SERVO DRIVE

Applications and Directions for Use

The BOSCH SERVO DRIVE is widely used in industrial automation, CNC machinery, and robotics for its reliable and precise control capabilities. This top-notch servo drive is easy to install and operate, making it ideal for both experienced engineers and new users alike. Simply mount the drive on a panel, connect via supported interfaces, and follow user guidelines for optimum system integration and performance.

Sample Policy, Certifications, and Shipping Information

We offer a competitive rate on BOSCH SERVO DRIVE samples, subject to quick dispatch upon request. Our product is supplied with the necessary certifications and comes carefully packaged in robust materials, ensuring the safe delivery of shipped goods. Clients can count on reliable service and transparent communication from order to fulfillment, making procurement straightforward throughout India.

FAQs of BOSCH SERVO DRIVE:

Q: How is the BOSCH SERVO DRIVE installed?

A: The BOSCH SERVO DRIVE is designed for panel mounting. Installation involves securing the drive to a suitable panel and connecting the necessary input, output, and feedback cables using the provided industrial screw terminals as per the user manual.Q: What are the main benefits of using a BOSCH SERVO DRIVE in industrial automation?

A: It offers precise control, high efficiency (>90%), rapid response times (2 ms), and robust protection features. These qualities improve machine accuracy, boost productivity, and reduce downtime in industrial settings.Q: Where can the BOSCH SERVO DRIVE be applied?

A: The drive is suitable for use in CNC machinery, robotics, and general industrial automation where precision motion and control are essential.Q: What is the process for connecting the drive to a control system?

A: Users can connect via RS232/RS485 or CANopen interfaces for communication. Position feedback is provided through an encoder connection, enabling seamless integration with existing automation systems.Q: When should maintenance be performed on this servo drive?

A: Regular inspection is recommended as part of routine system maintenance. Ensure the drives cooling system is clear and terminals are secure, particularly if operated in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BOSCH Used SERVO DRIVE Category

BOSCH SERVO DRIVE

Material : Industrial Grade Metal Enclosure

Features : Compact Design, High Precision Control, Builtin Safety Features

Connector Type : Screw Terminal

Output Type : Other, Digital/Analog

Product Type : Servo Drive

Application : CNC Machines, Robotics, Automation Systems

BOSCH SERVO DRIVE

Material : Industrial Grade Metal Housing

Features : Fieldbus Communication, Fast Response, Compact Design, Easy Integration

Connector Type : Industrial Terminal Block

Output Type : Other, Analog / Digital

Product Type : Servo Drive

Application : CNC Machines, Robotics, Automation, Material Handling

BOSCH SERVO DRIVE

Material : Highgrade Industrial Metal

Features : Compact Design, Precision Control, Integrated Safety, LED Status Indicators

Connector Type : Screw Terminal, Standard Industrial Plug

Output Type : Other, Variable Frequency Output

Product Type : Servo Drive

Application : Industrial Automation, CNC Machinery, Robotics

BOSCH SERVO DRIVE DS 15K 3301-D

Material : Industrial grade metal enclosure

Features : Short circuit protection, Overload protection, Fault diagnosis system, High dynamic response

Connector Type : Terminal block

Output Type : AC

Product Type : BOSCH SERVO DRIVE DS 15K 3301D

Application : CNC Machines, Robotics, Automation Systems

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry