BOSCH SERVO DRIVE

BOSCH SERVO DRIVE Specification

- Noise Level

- <65 dB

- Current Range

- 0-5A

- Power Supply

- AC

- Operating Temperature

- 0C to +50C

- Rated Power

- 1.5 kW

- Cooling Method

- Forced Air Cooling

- Output Current

- 3.8A

- Working Temperature

- 0C to +50C

- Connector Type

- Screw Terminal/Plug-in Connector

- Phase

- Three Phase

- Application

- Automation, CNC Machines, Robotics, Packaging

- Rated Current

- 3.8A

- Features

- Compact Design, High Precision Control, Fault Diagnostics

- Output Type

- Digital/Analog

- Power Factor

- >0.95

- Product Type

- Servo Drive

- Output Power

- 1.5 kW

- Output Frequency

- 0-300 Hz

- Input Voltage

- 380-480V AC

- Voltage Protection

- Overvoltage/Undervoltage

- Efficiency

- >95%

- Material

- Metal and High-Grade Engineering Plastic

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to +70C

- Weight

- Approx. 4.5 kg

- Mounting Type

- Panel Mount

- Start Up Time

- <3 seconds

- Life Expectancy

- >50,000 hours

- Communication Interface

- Ethernet, CANopen, Profibus, SERCOS

- Display Type

- LED/LCD Digital Display

- Protection Class

- Class I

- IP Rating

- IP20

- Vibration Resistance

- Up to 2G

- Control Method

- Vector Control / Position, Speed, Torque Control

- Model Number

- IndraDrive C

About BOSCH SERVO DRIVE

Versatile Applications and High-Precision Features

The BOSCH SERVO DRIVE IndraDrive C is not limited to one industry. Its design supports a wide range of uses, including CNC machinery, robotics, packaging, and general automation systems. Key features such as high-precision control, fault diagnostics, and compact build enable seamless integration. Whether for demanding industrial robotics or standard factory automation, this noble device stands out for its reliability, performance consistency, and broad compatibility with digital and analog outputs.

Domestic Market Coverage, Packaging, and Sample Policy

BOSCH SERVO DRIVE is widely available across Indias main domestic markets. Each unit arrives in sturdy, secure packaging to ensure protection during transit. For businesses considering bulk purchases or pilot runs, sample policies and exchange options are available. Competitive sale prices and proposal amounts can be tailored to suit requirements, providing both flexibility and value. Our streamlined process ensures your operational goals are efficiently met and supported long-term.

FAQs of BOSCH SERVO DRIVE:

Q: How does the BOSCH SERVO DRIVE benefit automation and CNC machine applications?

A: The BOSCH SERVO DRIVE IndraDrive C provides precise vector, position, speed, and torque control, which enhances the accuracy and efficiency of automation and CNC machining processes, resulting in improved productivity and reduced downtime.Q: What interfaces and communication protocols are supported by the IndraDrive C model?

A: This drive is equipped with advanced communication interfaces such as Ethernet, CANopen, Profibus, and SERCOS, ensuring flexible and seamless integration with various automation systems and network architectures.Q: Where can the BOSCH SERVO DRIVE be used apart from robotics and packaging?

A: Beyond robotics and packaging, this servo drive is suitable for use in general factory automation, assembly lines, CNC machining, and any application demanding high-precision, reliable servo performance.Q: What is the process for obtaining a sample or exploring proposal amounts?

A: Interested customers can contact our sales team for a proposal amount or to request a sample. We offer tailored sample policies and can assist with exchange guidelines to facilitate your evaluation and procurement needs.Q: When is the ideal time to consider using the BOSCH SERVO DRIVE in your equipment?

A: You should consider integrating the BOSCH SERVO DRIVE when you require high precision, rapid start-up, superior efficiency, and long-term reliability in your automation systems or machinery upgrades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BOSCH Used SERVO DRIVE Category

BOSCH SERVO DRIVE

Features : Shortcircuit Protection, Compact Design, High Precision Control

Output Type : Other, Digital

Phase : Other, Single/Three Phase

Application : Industrial Automation, CNC Machines, Robotics

Storage Temperature : 25C to +70C

Cooling Method : Fan Cooling

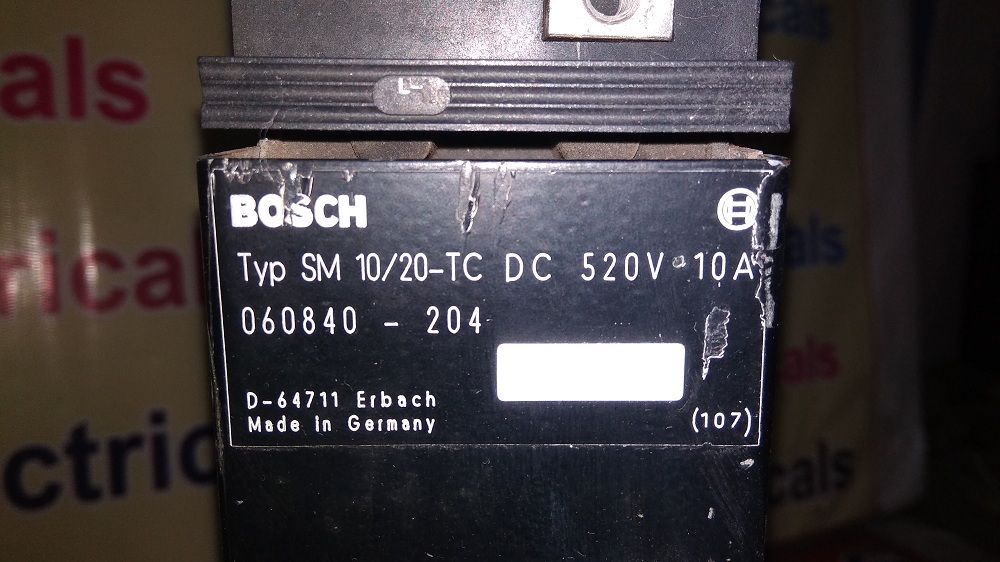

BOSCH SERVO DRIVE 10/20-TC

Features : Compact design, High Precision, Digital Control

Output Type : Other, Threephase AC

Phase : Three Phase

Application : Automation, CNC Machines, Robotics

Storage Temperature : 25C to +70C

Cooling Method : Forced Air Cooling

BOSCH SERVO DRIVE

Features : High Response, Precise Control, Compact Design

Output Type : Other, Digital/Analog

Phase : Other, Single/Three Phase

Application : Industrial Automation, CNC Machinery, Robotics

Storage Temperature : 25C to 70C

Cooling Method : Forced Air Cooling

BOSCH A.C SERVO DRIVE

Features : Short circuit protection, Overheat protection, Compact Size, Dynamic Response

Output Type : Other, Threephase AC

Phase : Three Phase

Application : Industrial automation, CNC machinery, Packaging, Robotics

Storage Temperature : 20C ~ 70C

Cooling Method : Forced air cooling

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry