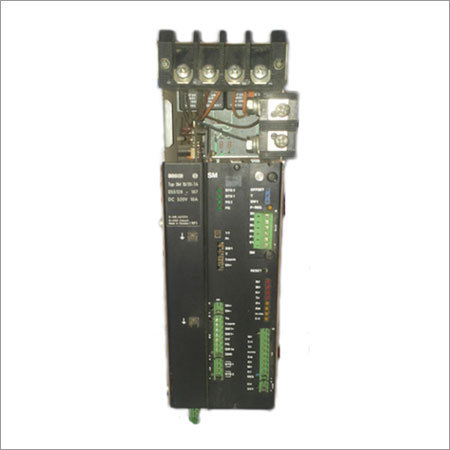

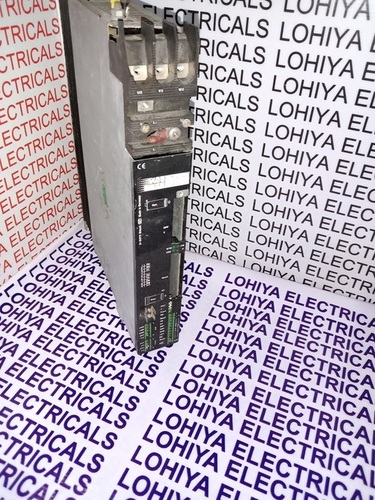

BOSCH SERVO DRIVE

BOSCH SERVO DRIVE Specification

- Cooling Method

- Forced Air Cooling

- Operating Temperature

- 0C to 55C

- Features

- Short Circuit Protection, Overload Protection, Compact Design, Easy Installation

- Power Factor

- >0.98

- Current Range

- 0-8A

- Output Current

- 7.5A

- Connector Type

- Screw Terminal

- Output Type

- Digital/Analog

- Power Supply

- AC 220-240V, 50/60Hz

- Rated Current

- 7A

- Phase

- Single/Three Phase

- Rated Power

- 1.5 kW

- Working Temperature

- 0C to 55C

- Application

- Industrial Automation, CNC Machines, Robotics

- Noise Level

- <60 dB

- Product Type

- Servo Drive

- Output Power

- 1.5 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 220-240V AC

- Voltage Protection

- Over/Under Voltage Protection

- Efficiency

- >95%

- Material

- Aluminium Alloy Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to 70C

- Weight

- 2.8 kg

- Control Method

- Vector Control / V/f Control

- Communication Interface

- RS232, CANopen, Ethernet

- Compatible Motors

- AC Servo Motors

- Protection Grade

- IP20

- Display Type

- LED / Digital Display

- Mounting Type

- DIN Rail / Panel Mount

- Brake Control

- Integrated Dynamic Brake

- Status Indication

- LED Indicators

- Response Time

- < 1 ms

- Firmware Update

- USB / Network

- Remote Monitoring

- Supported

About BOSCH SERVO DRIVE

Discover the BOSCH SERVO DRIVE, a majestic new release blending innovation and reliability for industrial automation at the best price. Engineered with a robust aluminium alloy housing, this gilt-edged drive supports AC servo motors and offers wondrous performance via RS232, CANopen, or Ethernet interfaces. Its advanced vector and V/f controls, integrated dynamic brake, and premium protection (IP20) ensure seamless, safe operations. With efficiency over 95%, remote monitoring, LED/digital display, and broad mounting options, this compact solution is ideal for CNC machines, robotics, and diverse industrial applications. Purchase today for optimal precision and durability.

Applications Across Diverse Industrial Settings

The BOSCH SERVO DRIVE shines in a wondrous array of applications, including plant automation, CNC machine operations, and cutting-edge robotics. Its compatibility with both single and three-phase systems and integration with different media ensures gilt-edged performance under various industrial environments. Suited for high-precision tasks, this drive finds its place in central processing units, manufacturing lines, and automated warehouses, making it indispensable for sectors where reliability and control are paramount.

Domestic Market Shipping & Valuation Advantages

Our main domestic market covers all major industrial hubs across India. The BOSCH SERVO DRIVE is shipped securely from FOB ports with meticulous attention to freight and safe packaging. Benefit from available product samples for easy valuation and testing before complete purchase. We ensure reliable and timely delivery with secure shipping protocols, enabling clients to experience the drives power and flexibility with total confidence in product safety and transaction transparency.

Applications Across Diverse Industrial Settings

The BOSCH SERVO DRIVE shines in a wondrous array of applications, including plant automation, CNC machine operations, and cutting-edge robotics. Its compatibility with both single and three-phase systems and integration with different media ensures gilt-edged performance under various industrial environments. Suited for high-precision tasks, this drive finds its place in central processing units, manufacturing lines, and automated warehouses, making it indispensable for sectors where reliability and control are paramount.

Domestic Market Shipping & Valuation Advantages

Our main domestic market covers all major industrial hubs across India. The BOSCH SERVO DRIVE is shipped securely from FOB ports with meticulous attention to freight and safe packaging. Benefit from available product samples for easy valuation and testing before complete purchase. We ensure reliable and timely delivery with secure shipping protocols, enabling clients to experience the drives power and flexibility with total confidence in product safety and transaction transparency.

FAQs of BOSCH SERVO DRIVE:

Q: How can the BOSCH SERVO DRIVE be mounted for optimal performance?

A: The BOSCH SERVO DRIVE offers flexible installation via DIN rail or panel mounting, allowing you to select the best layout for your industrial setup and ensuring efficient use of control cabinet space.Q: What remote monitoring features are available with this servo drive?

A: This drive supports real-time remote monitoring via USB or network connections, letting users track operational status, perform diagnostics, and update firmware seamlessly from any connected location.Q: Where is the BOSCH SERVO DRIVE most commonly used?

A: It is ideally employed in industrial automation, CNC machines, and robotics, excelling in high-precision and demanding environments that require reliable motion control and compact solutions.Q: What makes the BOSCH SERVO DRIVE beneficial for plant applications?

A: Its integrated dynamic brake, short-circuit and overload protection, and fast response time (<1 ms) provide stable, safe, and uninterrupted operation, enhancing plant efficiency and minimizing downtime.Q: What is the process for updating the firmware on this device?

A: Firmware can be conveniently updated using a USB or over the network, ensuring that the BOSCH SERVO DRIVE stays current with the latest performance and security enhancements.Q: How does over/under voltage protection work in this drive?

A: Built-in over/under voltage protection automatically detects irregularities in voltage supply, promptly safeguarding the device and connected equipment from potential damage, thereby lengthening service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in BOSCH Used SERVO DRIVE Category

BOSCH POWER SUPPLY NT 1

Application : Industrial Automation

Noise Level : Low

Working Temperature : 10C to +55C

Input Voltage : 110230 V AC

Rated Current : 5 A

Phase : Single Phase

BOSCH SM 10,20-TA (2)

Application : Industrial automation

Noise Level : Low

Working Temperature : 0C to 40C

Input Voltage : 220V AC

Rated Current : 20A

Phase : Single Phase

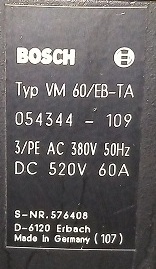

BOSCH SERVO DRIVE 520V DC

Application : Industrial Automation, CNC Machines, Robotics

Noise Level : <65 dB

Working Temperature : 0C to +50C

Input Voltage : 400 to 520V DC

Rated Current : 14 A

Phase : Three Phase

BOSCH SM 1 5 3 TC1 1070075977 103 CNC SERVO DRIVE

Application : CNC machinery automation, robotics

Noise Level : Low ( 55 dB)

Working Temperature : 0C to +45C

Input Voltage : 3 x 380 480 V AC

Rated Current : 3.5 A

Phase : Three Phase

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry