Call:

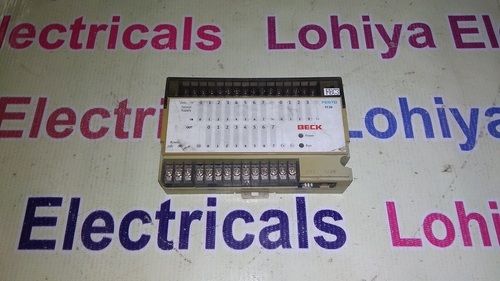

BECK PLC

BECK PLC Specification

- Installation Type

- DIN Rail Mountable

- Output

- Digital and Analog Outputs

- Connectivity Type

- RS232/RS485, Ethernet (model dependent)

- Mounting Type

- DIN Rail Mount

- Frequency

- 50/60 Hz

- Usage & Applications

- Factories, Building Automation, Machine Control

- Display

- LED Status Indicators

- Switch Type

- Electronic Switching

- Current

- 24 V DC

- Sensor Type

- Compatible with various process sensors

- Phase

- Single Phase

- Features

- Modular Expansion, Compact Design, Integrated Communication Ports

- IP Rating

- IP20

- Measuring Range

- Depends on module configuration

- Protection Level

- Integrated Overload/Short Circuit Protection

- Product Type

- PLC (Programmable Logic Controller)

- Operating Temperature

- -20C to +60C

- Working Temperature

- -20C to +60C

- Input

- Digital and Analog Inputs

- Application

- Industrial Automation, Process Control

- Supply Voltage

- 24 V DC

- Accuracy

- High-precision control, 1% (system dependent)

- Dimension (L*W*H)

- 130 mm x 70 mm x 115 mm (approx.)

- Weight

- Approx. 450 g

- Power Consumption

- Max. 5 W

- Storage Temperature

- -40C to +85C

- Case Material

- High-strength plastic

- Communication Protocols

- Modbus TCP/IP, Profibus, CANopen (dependent on model)

- Expansion Capability

- Supports I/O expansion modules

- Response Time

- <0.5 ms

- Programming Software

- Beck IPC@CHIP (compatible software)

- Program Memory

- 512 kB 2 MB (Depending on model)

- Environment

- For indoor installation only

About BECK PLC

Discover the BECK PLCa marvel of industrial automation, designed for flexibility and dazzling performance. With a program memory of 512 kB to 2 MB, this PLC adapts seamlessly to diverse factory and process control needs. Pick yours from models supporting expansion capabilities, ultimate connectivity options like Modbus TCP/IP, Profibus, and CANopen, and enjoy robust, high-precision control. Fresh technology means rapid response times (<0.5 ms), easy installation, and reliable power efficiency. Access rich featuresintegrated protection, modular design, and LED indicatorsensuring smooth, safe operation for every application.

BECK PLC: Versatile Applications and Competitive Edge

The BECK PLC thrives in application media such as factories, building automation, and machine control. Its suitability for various types of usagedigital and analog input/output controlstems from modular expansion, compact build, and powerful integrated ports. Primary competitive advantages include rapid response, high accuracy (1%), reliable overload/short circuit protection, and broad sensor compatibility, giving BECK PLC a superb edge in precision-driven environments requiring robust and adaptable process management.

Export Markets, Transport, and Sample Policy for BECK PLC

BECK PLCs main export markets span global industrial sectors, handled via prompt FOB port dispatch. When placing a purchase order, youre assured a clear asking price, systematic order processing, and dependable goods transport to your location. Sample policy is designed for customer trustsample units are provided upon request, allowing customers to evaluate quality and compatibility before bulk purchases. All steps are streamlined for efficient international transactions, supporting clients worldwide.

BECK PLC: Versatile Applications and Competitive Edge

The BECK PLC thrives in application media such as factories, building automation, and machine control. Its suitability for various types of usagedigital and analog input/output controlstems from modular expansion, compact build, and powerful integrated ports. Primary competitive advantages include rapid response, high accuracy (1%), reliable overload/short circuit protection, and broad sensor compatibility, giving BECK PLC a superb edge in precision-driven environments requiring robust and adaptable process management.

Export Markets, Transport, and Sample Policy for BECK PLC

BECK PLCs main export markets span global industrial sectors, handled via prompt FOB port dispatch. When placing a purchase order, youre assured a clear asking price, systematic order processing, and dependable goods transport to your location. Sample policy is designed for customer trustsample units are provided upon request, allowing customers to evaluate quality and compatibility before bulk purchases. All steps are streamlined for efficient international transactions, supporting clients worldwide.

FAQs of BECK PLC:

Q: How does the modular expansion capability of the BECK PLC benefit users?

A: The modular expansion allows users to add I/O modules as needed, enabling scalable solutions for growing process requirements without replacing the main controller.Q: What type of applications is the BECK PLC suitable for?

A: It is ideal for industrial automation, building automation, and machine control, where high precision, reliable networking, and versatile I/O configurations are critical.Q: When should I choose a specific communication protocol model?

A: Your choice should depend on your applications network requirements; select models with Modbus TCP/IP, Profibus, or CANopen support based on existing system infrastructure and connectivity needs.Q: Where can the BECK PLC be installed?

A: The BECK PLC is designed exclusively for indoor installations, ensuring stable performance and protection from environmental extremes.Q: What are the protective features integrated in the BECK PLC?

A: It includes built-in overload and short circuit protection to safeguard both the PLC and connected devices, enhancing operational safety and longevity.Q: How is sample evaluation handled for BECK PLC orders?

A: Sample units can be requested according to the sample policy, allowing for a thorough assessment of the PLCs performance and compatibility before finalizing a larger order.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in BECK PLC MODULE CPU HMI Category

BECK PLC

Accuracy : High switching reliability

Dimension (L*W*H) : 138 x 90 x 58 mm

Supply Voltage : 24V DC / 230V AC

Frequency : 50/60 Hz

Usage & Applications : Machine automation, process control

Application : Industrial Automation

BECK PLC

Accuracy : High Precision

Dimension (L*W*H) : 145mm x 90mm x 60mm

Supply Voltage : 24V DC

Frequency : 50/60 Hz

Usage & Applications : Factory Automation, Machine Control, Production Lines

Application : Industrial Automation, Process Control

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry