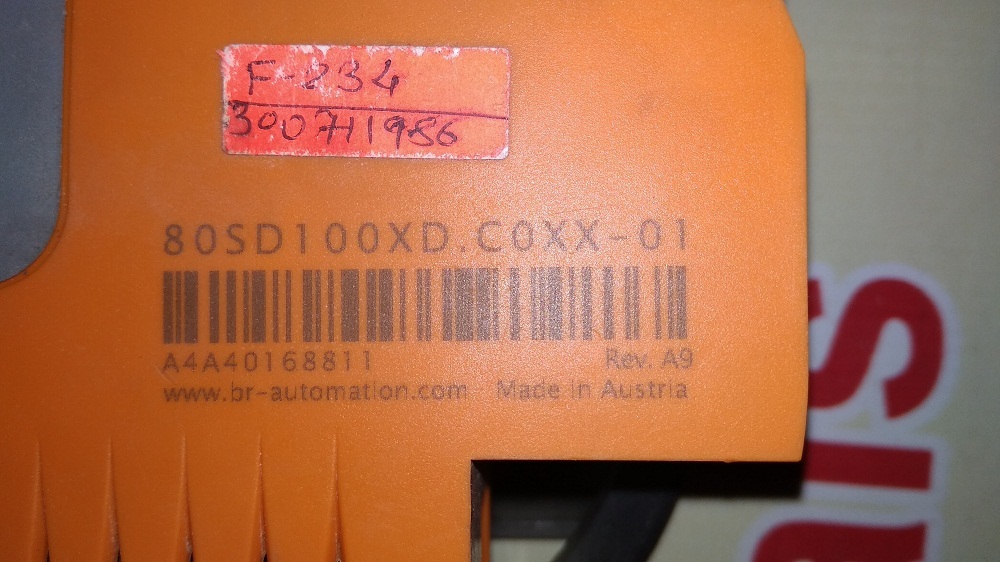

B & R ACOPOS

B & R ACOPOS Specification

- Mounting Type

- DIN rail or panel mount

- Output

- PWM output to servo motor

- Display

- Status LEDs, digital interface for diagnostics

- Phase

- Three Phase

- Protection Level

- Overvoltage, short circuit, thermal protection

- Features

- Integrated safety functions, modular design, compact size

- IP Rating

- IP20

- Installation Type

- Panel mounting, vertical positioning required

- Current

- Varies by model, typically 2A to 12A

- Usage & Applications

- CNC machines, robotics, packaging, material handling

- Connectivity Type

- Ethernet POWERLINK, X2X Link, digital/analog IO

- Frequency

- 50/60 Hz

- Product Type

- ACOPOS Servo Drive Module

- Operating Temperature

- 0C to +55C

- Working Temperature

- 0C to +55C

- Input

- 3 x 400-480 V AC; 50/60Hz

- Application

- Industrial automation, motion control systems

- Supply Voltage

- 24 V DC (control), 3 x 400-480 V AC (power)

- Accuracy

- High-precision control, depends on motor/feedback

- Dimension (L*W*H)

- Varies by model (e.g. 70 x 330 x 230 mm)

- Weight

- Approx. 4.5 kg (varies by model)

- Fieldbus Interfaces

- Integrated Ethernet POWERLINK, CAN bus ports

- Leakage Current

- < 3.5 mA

- Safety Functions

- Safe Torque Off (STO), Safely Limited Speed (SLS)

- Cooling Method

- Fan cooling / Forced air

- Firmware Update

- Upgradeable via network

- Number of Axes

- Scalable module; single to multi-axis

- Supported Protocols

- Ethernet POWERLINK, CANopen, Profibus (with expansion)

- Motor Compatibility

- Permanent Magnet Synchronous Motors, Asynchronous (Induction) Motors

- EMC Compliance

- EN 61800-3

About B & R ACOPOS

Versatility Meets Excellence: Areas of Application and Competitive Edge

B & R ACOPOS is engineered for a wide array of industrial automation tasks such as CNC machines, robotics, packaging, and material handling systems. Its competitive advantages include a modular, space-saving design, integrated safety functions, and unrivaled connectivity through fieldbus interfaces like Ethernet POWERLINK and CANopen. Designed for flexible usage, panel or DIN rail mounting, it thrives in demanding environments requiring scalable, high-accuracy motion controlmaking it the perfect choice for both suppliers and end-users in automated systems.

Certifications, Supply Efficiency, and Swift Fulfilment Guaranteed

B & R ACOPOS meets premium international standards, rated EMC compliant under EN 61800-3, and ensures robust safety and operational reliability. With a high monthly supply rate and quick dispatch from major FOB ports, customers benefit from minimal wait times and consistent product availability. The suppliers efficiency in order processing and reliable supply chain management further underscores B & R ACOPOS as a preferred motion-control solution in fast-paced industrial markets.

FAQs of B & R ACOPOS:

Q: How does the B & R ACOPOS module ensure safety during operations?

A: The B & R ACOPOS is equipped with integrated safety functions, such as Safe Torque Off (STO) and Safely Limited Speed (SLS), to protect operators and equipment by preventing unsafe motion and reducing risks during operation.Q: What types of motors are compatible with the B & R ACOPOS system?

A: This versatile system supports Permanent Magnet Synchronous Motors (PMSM) and Asynchronous (Induction) Motors, providing flexibility for various automation and motion control needs.Q: Where can the B & R ACOPOS be installed, and what mounting options are available?

A: The device is designed for panel mounting and vertical positioning but can also be installed on DIN rails, making it adaptable to most industrial control cabinets and automation setups.Q: What benefits do the modular design and scalable axes offer to users?

A: The modular architecture allows users to expand from single-axis to multi-axis configurations seamlessly. This scalability contributes to cost-effectiveness, system customization, and future-proofing of automation investments.Q: How is firmware upgraded on the B & R ACOPOS system?

A: Firmware updates can be performed via the network, enabling straightforward, remote upgrades that minimize downtime and keep the system operating at peak performance.Q: What is the process for monitoring system status and diagnostics?

A: Status LEDs and a digital diagnostic interface provide clear, real-time information on operational status and potential faults, facilitating quick troubleshooting and ensuring continuous system reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B & R ACOPOS MICRO 100D Category

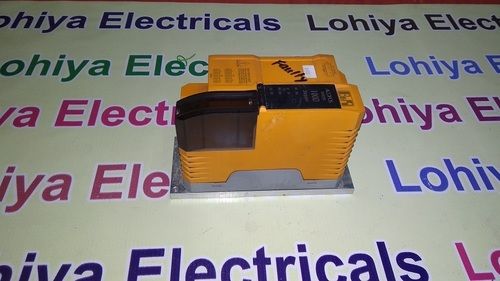

B & R ACOPOS MICRO 100D

Dimension (L*W*H) : 252 x 68 x 219 mm

Mounting Type : DIN rail mount

Output : 2 x up to 750 W (per axis)

Input : 24 VDC (control voltage), 110230 VAC (main power supply)

Phase : Single/Three phase (main supply)

Display : Status LEDs

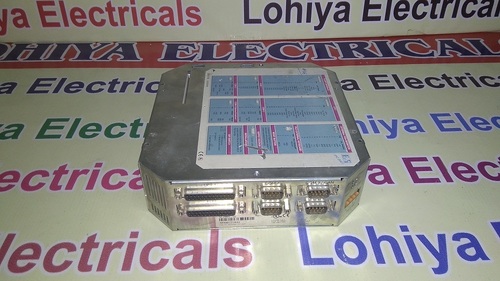

Lohiya B & R CONTROLLER

Dimension (L*W*H) : 110mm x 90mm x 60mm

Mounting Type : DIN Rail / Panel

Output : Digital/Analog

Input : Digital/Analog

Phase : Single

Display : LED/LCD

ACOPOS MICRO 100D

Dimension (L*W*H) : 120 x 85 x 45 mm

Mounting Type : Panel / DIN Rail

Output : Servo Motor Control

Input : 24V DC

Phase : Single Phase

Display : LED Status Indicators

B & R ACOPOS MICRO 100D

Dimension (L*W*H) : 60 mm x 170 mm x 132 mm (WxHxD)

Mounting Type : DIN Rail or Panel

Output : Continuous and peak AC output

Input : 3 x 400500 V AC, 50/60 Hz

Phase : Three Phase

Display : LED status indicators

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry