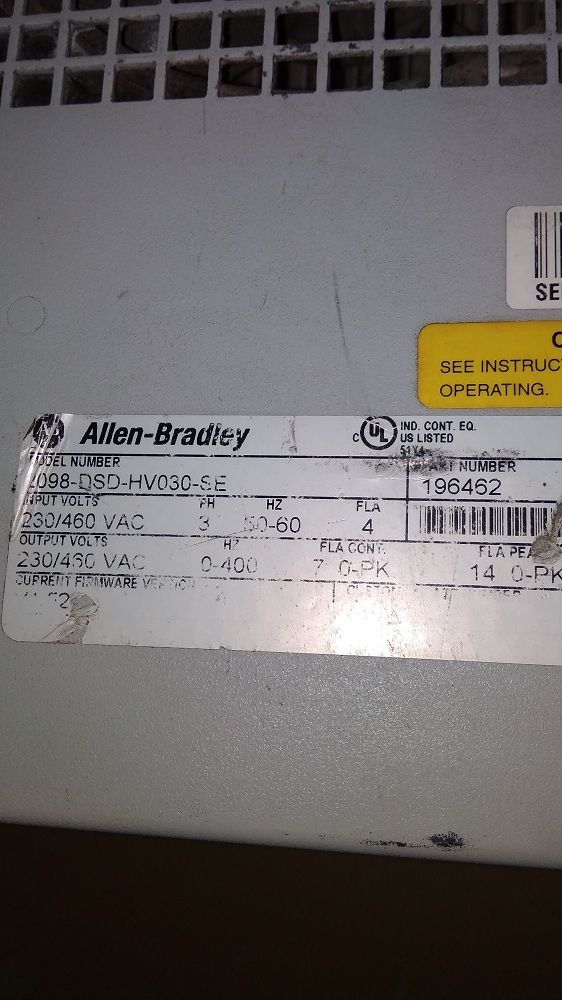

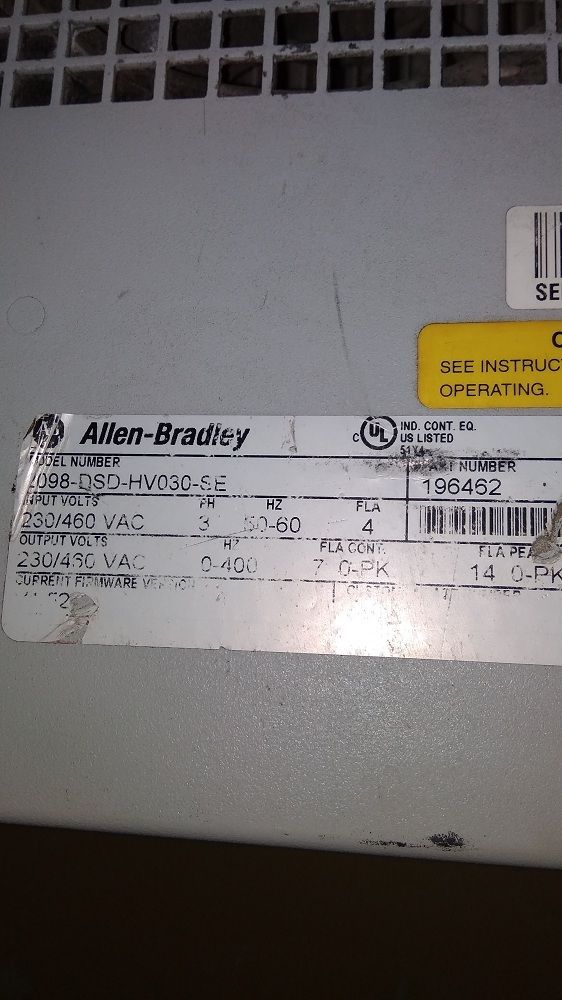

ALLEN BRADLEY SERVO DRIVE

ALLEN BRADLEY SERVO DRIVE Specification

- Noise Level

- <55 dB

- Output Current

- 2.5 A

- Working Temperature

- 0C to 55C

- Phase

- Single/Three Phase

- Connector Type

- Screw Terminal

- Application

- Industrial Automation, CNC Machines, Robotics

- Current Range

- 2.0 - 2.5 A

- Power Factor

- >0.90

- Features

- Overload and Short Circuit Protection, Precise Control, High Reliability

- Cooling Method

- Fan Cooled

- Rated Power

- 500 W

- Rated Current

- 2.5 A

- Output Type

- Digital/Analog

- Operating Temperature

- 0C to 55C

- Power Supply

- AC Supply

- Product Type

- Allen Bradley Servo Drive

- Output Power

- 500 W

- Output Frequency

- 50/60 Hz

- Input Voltage

- 100240 V AC

- Voltage Protection

- Over/Under Voltage Protection

- Efficiency

- >95%

- Material

- Metal Enclosure

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 70C

- Weight

- 2.1 kg

About ALLEN BRADLEY SERVO DRIVE

Versatile Usage and Application Spectrum

The ALLEN BRADLEY SERVO DRIVE is engineered for ultimate adaptability, serving pivotal roles in industrial automation, CNC machinery, and robotics integration. Used as a core motion control component, it excels in scenarios requiring high-precision operation, rapid response, and steadfast reliability. Whether you are automating production lines or achieving optimal movement in robotic arms, this servo drive ensures seamless and efficient system performance across various cutting-edge applications.

Certifications, Payment Terms, and Delivery Valuation

Recognized for stringent quality standards, the ALLEN BRADLEY SERVO DRIVE arrives with robust certifications, ensuring your investments valuation and compliance. Flexible payment terms accommodate diverse business expenditures, simplifying acquisition without compromise. Promptly shipped to meet your project timelines, the products delivery time aligns with industry best practices, reducing downtime and supporting quick system implementations. Trust in a process designed for both efficiency and assurance at every step.

FAQs of ALLEN BRADLEY SERVO DRIVE:

Q: How does the ALLEN BRADLEY SERVO DRIVE ensure precise motion control?

A: The servo drive utilizes advanced Vector Control and V/F Control methods, supported by incremental encoder and resolver feedback types, to deliver highly accurate and responsive motion control for a variety of automation tasks.Q: What types of industrial applications is this servo drive best suited for?

A: It is ideal for use in industrial automation, CNC machines, and roboticsany environment where precision, reliability, and efficient motion are crucial for optimal performance.Q: When should I consider using built-in dynamic braking?

A: Built-in dynamic braking is most beneficial during emergency stops or rapid deceleration, ensuring both safety and mechanical protection in high-speed or high-inertia applications.Q: Where can the ALLEN BRADLEY SERVO DRIVE be panel mounted?

A: The drive is designed to be mounted securely on standard industrial panels, making it suitable for control cabinets, machinery frames, and other designated installation points in industrial setups.Q: What is the process for setting up communication with the drive?

A: You can connect via RS232/RS485 or Ethernet interfaces using the screw terminal connectors. Integration with control systems is straightforward, supported by the drives robust communication protocols.Q: What are the benefits of the drives overload and short circuit protection features?

A: These built-in protection mechanisms help safeguard your equipment by automatically responding to electrical faults, prolonging drive lifespan and minimizing the risk of unexpected system failures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY 22A-B1P5N104 SERIES-A POWERFLEX 4 VFD 527 ADJUSTABLE FREQUENCY AC DRIVES

Power Supply : AC Power Supply

Operating Temperature : 10C to 50C

Cooling Method : Fan Cooled

Features : Integral keypad, Digital display, Fault diagnostics, Programmable I/O, RS485 communication

Application : Pumps, Fans, Conveyors, Machine Tools, Process Equipment

Connector Type : Screw Terminal

ALLEN-BRADLEY CAT 1794-PS12

Power Supply : 12V DC output

Operating Temperature : 0C to +55C

Cooling Method : Natural convection

Features : DIN rail mountable, compact size, easy installation, LED status indication

Application : Industrial automation, control panels, FLEX I/O systems

Connector Type : Removable terminal block

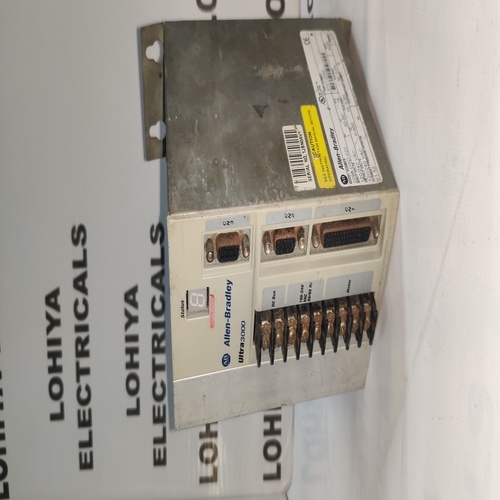

ALLEN BRADLEY 2098-DSD-020 ULTRA3000 DIGITAL SERVO DRIVE

Power Supply : AC Powered

Operating Temperature : 0C to 55C

Cooling Method : Fan Cooled

Features : Autotuning, Safe Torque Off, Digital Display, Diagnostics

Application : Industrial Automation, Motion Control

Connector Type : Plugin Connectors

Allen-Bradley SLC 100 1745-E101 B

Power Supply : Internal Power Supply

Operating Temperature : 0C to 60C

Cooling Method : Natural Air Cooling

Features : Programmable, Compact, Multiple I/O, Expansion Capable

Application : Industrial Automation, Process Control

Connector Type : Screw terminal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry