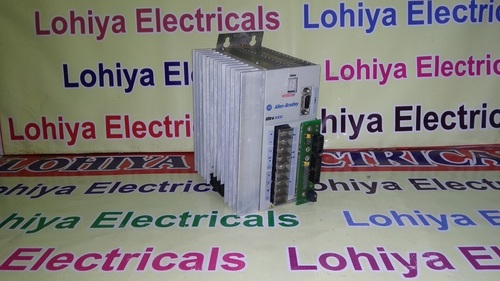

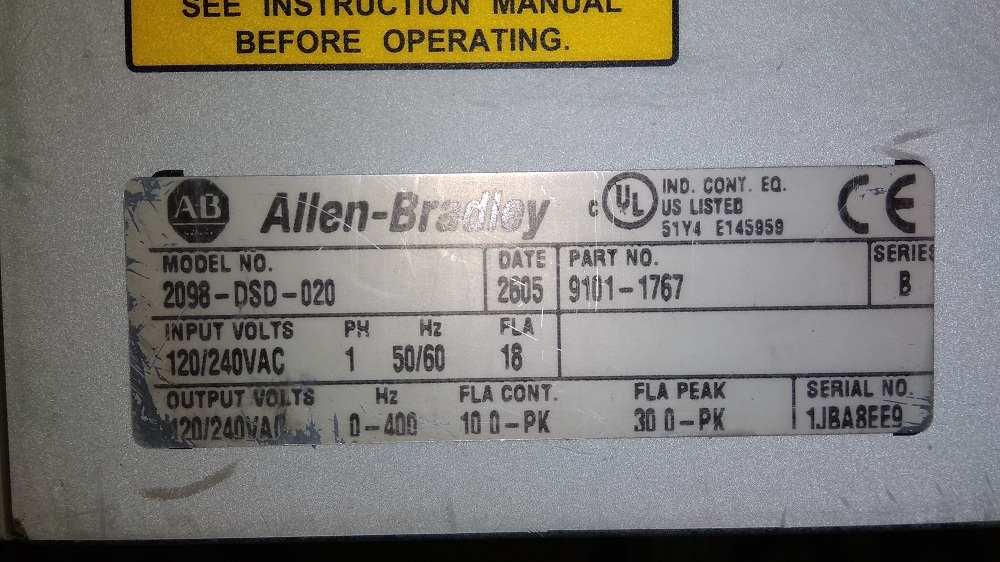

ALLEN BRADLEY SERVO DRIVE

ALLEN BRADLEY SERVO DRIVE Specification

- Phase

- Single / Three Phase

- Application

- Robotics, CNC Machines, Packaging & Material Handling

- Features

- Integrated protection, High-speed response, Compact design, Easy installation

- Operating Temperature

- 0C to 55C

- Rated Current

- 3.1 A

- Power Factor

- >0.95

- Power Supply

- AC 230V, 50/60Hz

- Noise Level

- <60 dB

- Working Temperature

- 0C to 55C

- Rated Power

- 750 W

- Cooling Method

- Forced Air Cooling

- Current Range

- 0.1 3.1 A

- Connector Type

- Screw terminal / Plug-in

- Output Type

- Digital/Analog

- Output Current

- 3.1 A

- Product Type

- Allen Bradley Servo Drive

- Output Power

- 750 W

- Output Frequency

- 0-500 Hz

- Input Voltage

- 230 V AC

- Voltage Protection

- Over voltage, Under voltage, Short circuit protection

- Efficiency

- >90%

- Material

- Metal Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 75C

- Weight

- Approx. 2.5 kg

- Frequency Response

- Up to 1 kHz

- Regeneration Capability

- Built-in braking circuit

- Startup Assistance

- Auto-tuning function

- Compatible Motors

- Servo Motors 100W to 750W

- Firmware Upgrade

- Supported

- Display Type

- LED numeric display

- Position Feedback

- Incremental/Absolute Encoder

- Control Method

- Vector Control, V/F Control

- Communication Ports

- RS232/RS485, EtherNet/IP

- Enclosure Rating

- IP20

- Mounting Type

- Panel Mount

About ALLEN BRADLEY SERVO DRIVE

Features, Commercial Advantages, and Applications of ALLEN BRADLEY SERVO DRIVE

The ALLEN BRADLEY SERVO DRIVE stands out for its integrated protection, high-speed vector control, and versatile communication ports. Its compact build, LED numeric display, and auto-tuning function streamline setup and ensure reliable performance in demanding environments. Ideal for robotics, CNC machining, packaging, and material handling, businesses gain precise motion control and consistent productivity, making this drive a top-tier choice for commercial automation.

Payment Terms, Export Markets, and Delivery Process for ALLEN BRADLEY SERVO DRIVE

Valuation is highly competitive, and stock is ready for immediate order fulfillment. We offer flexible payment terms to suit international and domestic buyers. Main export markets are Asia, Middle East, and Europe. Our efficient packing & dispatch process ensures secure and timely delivery. Expect quick turnaround, with expedited shipping options available for urgent needsyour ALLEN BRADLEY SERVO DRIVE reaches you reliably and on schedule.

FAQs of ALLEN BRADLEY SERVO DRIVE:

Q: How does the ALLEN BRADLEY SERVO DRIVE enhance industrial automation processes?

A: The servo drive ensures precise and efficient motion control, supporting rapid frequency response up to 1kHz. Its advanced vector control and integration capabilities allow seamless automation in robotics, CNC machinery, and material handling systems.Q: What are the main protection features included in the ALLEN BRADLEY SERVO DRIVE?

A: The unit offers built-in protection against over-voltage, under-voltage, and short circuits, along with a built-in braking circuit for safe operation and high reliability.Q: When should I consider upgrading the firmware of my servo drive?

A: Firmware updates should be performed when new features or improvements are released or if recommended by technical support for enhanced performance and system compatibility.Q: Where can the ALLEN BRADLEY SERVO DRIVE be installed?

A: It is designed for panel-mount installation in industrial settings such as factories or production lines requiring advanced motion control, especially in robotics or CNC applications.Q: What is the process for setting up and tuning the servo drive?

A: Install the drive using screw or plug-in terminals, connect to your motor and control network, then use the auto-tuning function and LED display to achieve optimal setup for your chosen application.Q: What are the main commercial benefits of choosing this servo drive?

A: The drives high efficiency, reliability, and ease of installation minimize downtime, maximize productivity, and reduce operational costs in various automation environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

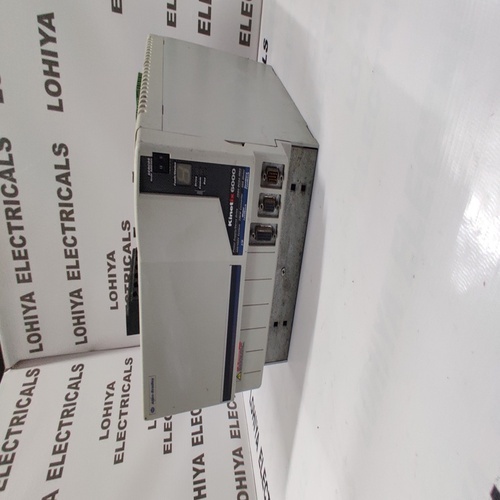

ALLEN BRADLEY 2094-BC04-M03 KINETIX 6000 SERVO DRIVE

Product Type : Servo Drive

Operating Temperature : 0C to +55C

Material : Metal (Sheet Steel), HighImpact Plastic

Features : Safe TorqueOff, MultiAxis Support, Digital Feedback, Ethernet Communication, Diagnostic LEDs

Weight : 7.8 kg

Application : Industrial Automation, Packaging, Robotics, Motion Control Systems

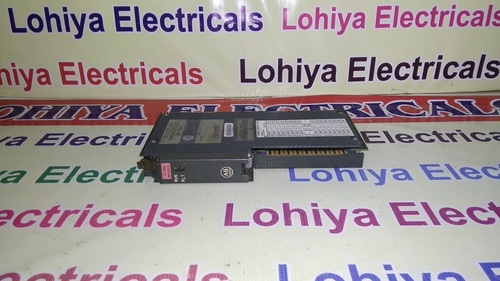

ALLEN BRADLEY INPUT MODULE

Product Type : Input Module

Operating Temperature : 0C to 60C

Material : Plastic Housing with Electronic Components

Features : LED Indicator, Compact Design, Easy DIN Rail Mounting

Weight : Approximately 150g

Application : Industrial Automation, PLC Systems

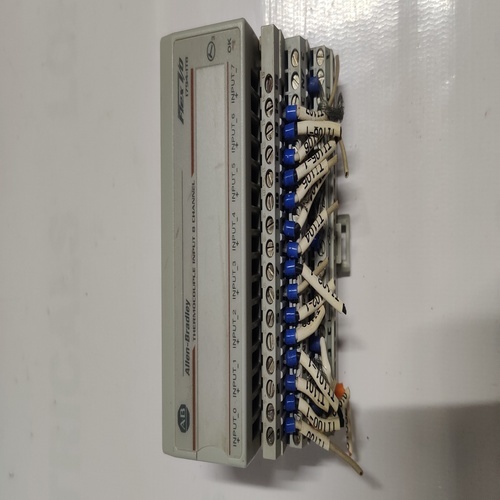

ALLEN-BRADLEY 1794-IT8 MODULE

Product Type : Thermocouple Input Module

Operating Temperature : 0C to 55C (32F to 131F)

Material : Industrial grade plastic

Features : 8 thermocouple inputs, LED status indicators, opencircuit detection, coldjunction compensation, removable terminal block

Weight : Approx. 80 g (0.18 lbs)

Application : Industrial automation, temperature monitoring

ALLEN BRADLEY MODULE

Product Type : PLC (Programmable Logic Controller) Module

Operating Temperature : 0C to 55C

Material : Plastic enclosure

Features : Programmable logic module Fault diagnostics

Weight : Approximately 500g

Application : Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry