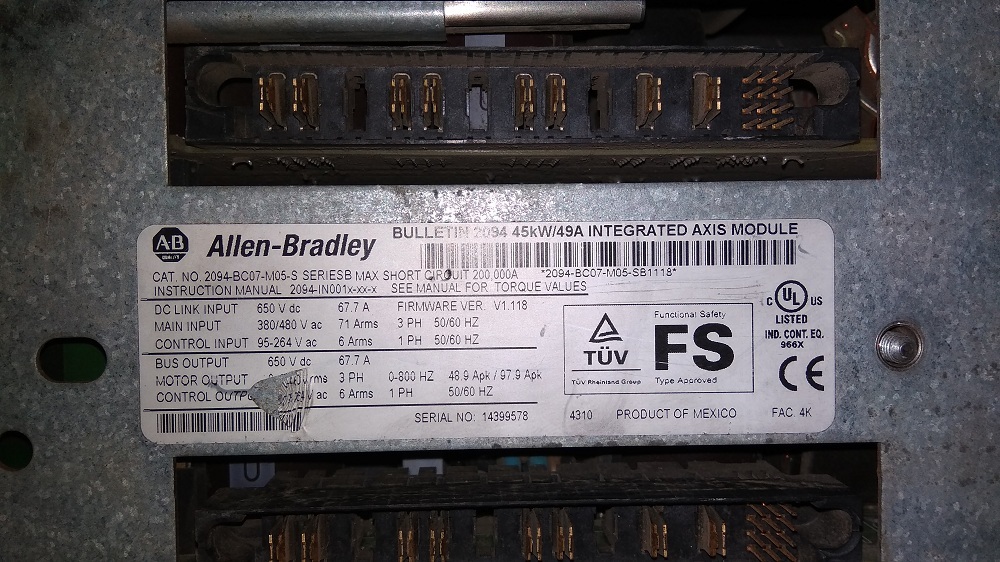

ALLEN BRADLEY SERVO DRIVE

ALLEN BRADLEY SERVO DRIVE Specification

- Features

- High Precision Control, Fast Response, Programmable, Auto-tuning, Compact Design

- Application

- Industrial Automation, CNC, Robotics

- Cooling Method

- Forced Air Cooling

- Noise Level

- <50 dB

- Operating Temperature

- 0C to 50C

- Power Supply

- AC Mains

- Current Range

- 0-4.2 A

- Working Temperature

- 0C to 50C

- Output Current

- 4.2 A

- Output Type

- Digital / Analog

- Connector Type

- Screw Terminal/Plug-in

- Power Factor

- >0.95

- Phase

- Single Phase / Three Phase

- Rated Power

- 750 W

- Rated Current

- 4.2 A

- Product Type

- Servo Drive

- Output Power

- 750 W

- Output Frequency

- 0-600 Hz

- Input Voltage

- 200-240 VAC, 1/3 Phase

- Voltage Protection

- Overvoltage, Undervoltage, Short Circuit, Overcurrent

- Efficiency

- Up to 95%

- Material

- Metal Enclosure

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 70C

- Weight

- Approx. 2.5 kg

- Communication Interface

- RS232, RS485, EtherNet/IP, CANopen

- Brake Control

- Built-in Braking Transistor

- Protection Class

- IP20

- Insulation Resistance

- >100 M at 500 VDC

- Mounting Type

- Panel Mount

- Vibration Resistance

- 5.9 m/s (10 to 55 Hz)

- Display Type

- LED / Digital

- Control Method

- Vector Control / V/F Control

- Pulse Input

- Up to 200 kHz

- Relative Humidity

- 5% - 95% (non-condensing)

About ALLEN BRADLEY SERVO DRIVE

Versatile Usage for Advanced Applications

The ALLEN BRADLEY SERVO DRIVE excels in demanding industrial automation, CNC machines, and robotic systems. This machine boasts features such as high-precision control, fast response, auto-tuning, and a compact, sturdy design. With both single-phase and three-phase compatibility and superior adaptability, it serves a wide range of usage types, enhancing performance in every application. Its robust build and multi-interface support make it ideal for modern, challenging environments where dependability is essential.

Packaging, Delivery & Export Information

Each ALLEN BRADLEY SERVO DRIVE is carefully packed in premium materials to ensure safety during transit. After order completion, the drive is handed over to reliable cargo partners for swift delivery from the chosen FOB port in India. With a focus on global demand, our major export markets include Asia, Africa, the Middle East, and Europe. Timely delivery and secure shipment are promised, ensuring your order reaches you efficiently and in perfect condition.

FAQs of ALLEN BRADLEY SERVO DRIVE:

Q: How does the ALLEN BRADLEY SERVO DRIVE support different communication protocols?

A: The servo drive comes equipped with multiple communication interfaces, including RS232, RS485, EtherNet/IP, and CANopen, enabling seamless integration with a variety of industrial systems and controllers.Q: What are the primary benefits of choosing this servo drive for industrial applications?

A: This servo drive offers high-precision vector control, fast response times, wide compatibility, superior protection features, and efficient operation, making it a reliable choice for CNC machines, robotics, and advanced automation.Q: When should the built-in braking transistor feature be utilized?

A: The built-in braking transistor is used during rapid deceleration or emergency stops, safely controlling the motors kinetic energy and preventing potential overloads or damage to the system.Q: Where is the ideal mounting location for this servo drive?

A: Designed for panel mounting, the ALLEN BRADLEY SERVO DRIVE should be installed in a well-ventilated control panel within the recommended operating temperature range (0C to 50C) to ensure optimal performance.Q: What is the process for connecting power and control signals to the drive?

A: The servo drive provides screw terminal and plug-in connectors for easy and secure wiring of both power and control signals, ensuring quick installation and dependable connections.Q: How does the drive maintain noise levels below 50 dB during operation?

A: A forced air cooling system efficiently dissipates heat, allowing the drive to operate quietly, keeping noise levels under 50 dB, and ensuring a comfortable work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY POWER SUPPLY

Product Type : Industrial Power Supply

Output Type : DC

Connector Type : Screw Terminal

Storage Temperature : 40C to +85C

Operating Temperature : 25C to +70C

Power Supply : Switch Mode Power Supply (SMPS)

ALLEN-BRADLEY CAT 1786-RPA.B

Product Type : ALLENBRADLEY CAT 1786RPA.B

Output Type : Other, Redundant Power Supply Adapter

Connector Type : ControlNet Specific

Storage Temperature : 40C to 85C

Operating Temperature : 0C to 60C

Power Supply : Redundant Adapter

ALLEN BRADLEY PLC 1794-IE4XOE2

Product Type : Analog Input/Output Module

Output Type : Other, 4 Analog Input, 2 Analog Output

Connector Type : FLEXBUS Connector

Storage Temperature : 40C to 85C

Operating Temperature : 20C to 55C

Power Supply : 24V DC

ALLEN BRADLEY HMI 2711C-T4T

Product Type : PanelView C400

Output Type : Other, Display Output

Connector Type : Standard RJ45 Connector

Storage Temperature : 20C to 70C

Operating Temperature : 0C to 50C

Power Supply : External 24V DC Power

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry