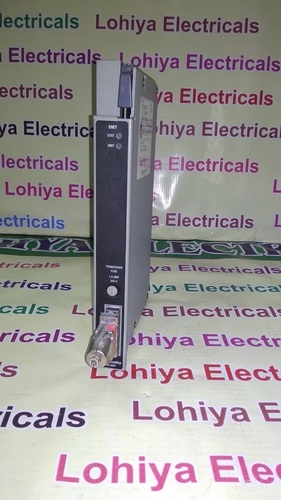

ALLEN BRADLEY POWER SUPPLY

ALLEN BRADLEY POWER SUPPLY Specification

- Rated Current

- 2.5A

- Power Factor

- >0.95

- Output Current

- 2.5A

- Noise Level

- <1% Ripple & Noise

- Current Range

- 2A - 2.5A

- Application

- Industrial Automation, Control Panels, PLCs

- Phase

- Single Phase

- Cooling Method

- Natural Air Cooling

- Features

- DIN Rail Mount, LED Indicator, Compact Design, High Reliability

- Connector Type

- Screw Terminal

- Operating Temperature

- -25C to +70C

- Working Temperature

- -25C to +70C

- Rated Power

- 60W

- Output Type

- DC

- Power Supply

- Switch Mode Power Supply (SMPS)

- Product Type

- Power Supply Module

- Output Power

- 60W

- Output Frequency

- 50/60Hz

- Input Voltage

- 100-240V AC

- Voltage Protection

- Overvoltage, Overload, Short Circuit Protection

- Efficiency

- >89%

- Material

- Plastic, Metal Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to +85C

- Weight

- approx. 480g

- Start-up Time

- <1s at 230V AC

- MTBF (Mean Time Between Failures)

- >500,000 hours

- Mounting Type

- DIN Rail Mounting

- Output Voltage

- 24V DC

- Dimensions (HxWxD)

- 90 x 100 x 60 mm

- Input Frequency

- 47-63Hz

- Indication

- LED Status Indicator

- Humidity

- 5 - 95% RH (Non-condensing)

- Adjustable Output Voltage

- Yes

- Protection Class

- IP20

About ALLEN BRADLEY POWER SUPPLY

ALLEN BRADLEY POWER SUPPLY P5Robust and Compact Power Solution

The Allen Bradley Power Supply stands out with its compact 90 x 100 x 60 mm dimensions, making it an excellent choice for limited-space installations. Despite its size, it delivers a dependable 60W output with a power factor above 0.95 and exceptional efficiency, ensuring reduced energy consumption and operational cost savings in industrial environments.

Advanced Protection and Reliability

With integrated overvoltage, overload, and short circuit protection, this power supply is engineered for maximum safety and reliability. Its Mean Time Between Failures (MTBF) exceeds 500,000 hours, highlighting its durability for continuous use in critical control systems, automation setups, and PLC applications.

Simple Installation and Operation

Installation is made straightforward with DIN rail mounting and screw terminal connectors. The LED status indicator provides immediate feedback on operation status. Adjustable output voltage empowers users to fine-tune for customized requirements, supporting a variety of equipment seamlessly in demanding industrial settings.

FAQs of ALLEN BRADLEY POWER SUPPLY:

Q: How is the Allen Bradley Power Supply installed in control panels?

A: This power supply is designed for simple DIN rail mounting. Users attach the unit directly onto a standard DIN rail in the control panel, ensuring a secure, tool-minimal installation. The screw terminal connectors make wiring both fast and reliable, streamlining setup and maintenance.Q: What protections does this power supply offer for connected equipment?

A: It features comprehensive protection, including overvoltage, overload, and short circuit safeguards. These ensure both the power supply and downstream equipment are shielded from voltage surges or faults, enhancing operational safety and prolonging device lifespan.Q: When is the LED status indicator used, and what does it signal?

A: The LED status indicator provides real-time feedback on the operational state of the unit. It signals power on, fault conditions, or output status, allowing users to diagnose issues quickly and maintain system uptime in automation or control environments.Q: Where can this power supply be effectively used?

A: Its robust build and wide operational range make it ideal for industrial automation, control panels, and PLCs used in manufacturing, process control, and building management systems, especially where continuous, reliable 24V DC power is essential.Q: What is the process for adjusting the output voltage?

A: Users can adjust the output voltage via a potentiometer located on the power supply. This allows for fine-tuning the output to match the requirements of different connected devices, offering flexibility for varying industrial applications.Q: How does the power supply benefit industrial automation systems?

A: With its high efficiency, reliable protection mechanisms, and robust design, the power supply ensures stable power delivery, reduces downtime, and supports uninterrupted operation of automation equipment, leading to more consistent productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY POWER SUPPLY

Input Voltage : 100240V AC

Material : Metal Housing

Weight : 0.95 kg

Cooling Method : Natural Air Cooling

Application : Industrial Automation, Control Panels, Machinery

Storage Temperature : 40C to 85C

ALLEN-BRADLEY SLC 500 POWER SUPPLYCAT 1746-P2

Input Voltage : 85240V AC

Material : Metal casing

Weight : 0.7kg

Cooling Method : Natural Cooling

Application : Industrial automation

Storage Temperature : 4085C

ALLEN-BRADLY POWER SUPPLY 96219075 A01-P4R/C

Input Voltage : 100240 V AC

Material : Metal

Weight : Approx. 0.6 kg

Cooling Method : Natural Air Cooling

Application : Industrial Automation

Storage Temperature : 40C to +85C

ALLEN BRADLEY CPU 1785-ENET A

Input Voltage : Supplied from PLC Backplane

Material : Highgrade Industrial Plastic and Metal

Weight : Approx. 0.65 kg

Cooling Method : Natural convection/ambient air

Application : For PLC communication, EtherNet/IP networks, and SLC 500/PLC5 systems.

Storage Temperature : 40C to +85C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry