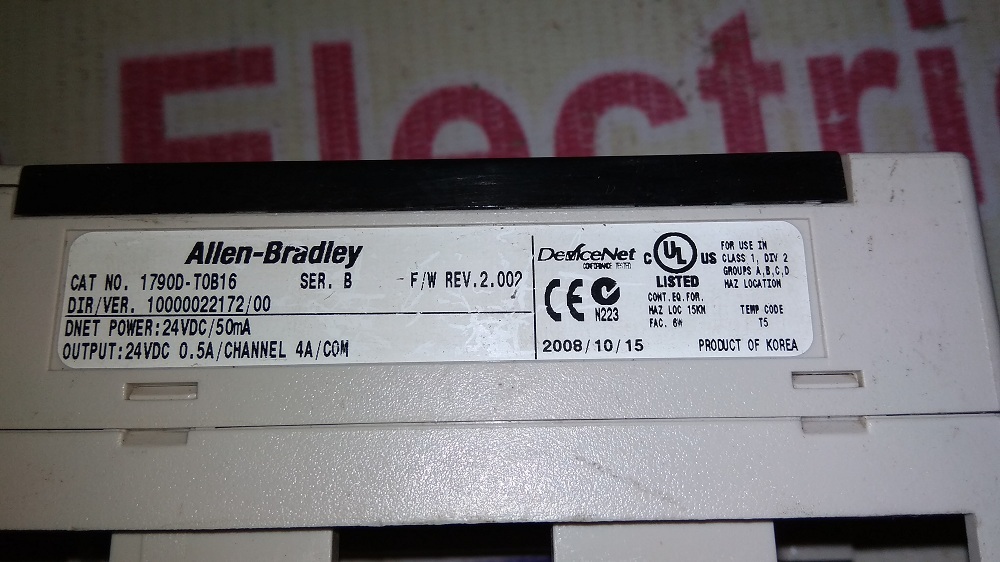

ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Specification

- Rated Power

- 12W

- Output Type

- Digital/Analog

- Current Range

- 0.1A - 0.5A

- Working Temperature

- 0C to 60C

- Noise Level

- <45dB

- Features

- Modular Design, Expandable I/O, Integrated Communication Ports (RS232/RS485), Real-Time Clock

- Application

- Industrial Automation, Process Control

- Cooling Method

- Natural Air Cooling

- Connector Type

- Screw Terminal

- Power Supply

- AC Supply

- Rated Current

- 0.5A

- Output Current

- Max 0.5A per Channel

- Power Factor

- >0.9

- Operating Temperature

- 0C to 60C

- Phase

- Single/Three Phase Supported

- Product Type

- PLC (Programmable Logic Controller)

- Output Power

- 24VDC, 0.5A

- Output Frequency

- 50/60Hz

- Input Voltage

- 100-240VAC

- Voltage Protection

- Over Voltage/Under Voltage Protection

- Efficiency

- Up to 85%

- Material

- Industrial Grade Flame Retardant Plastic & Metal

- Line Regulation

- 1%

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 350g

About ALLEN BRADLEY PLC

Versatile Application Across Industrial Surfaces

The ALLEN BRADLEY PLC is engineered for deployment on DIN Rail-mounted surfaces, ensuring secure installation in industrial control panels. Its robust architecture, with flame-retardant plastic and metal casing, suits diverse application media such as manufacturing lines, process automation, and advanced machinery. Well-suited for continuous operation in challenging environments, it supports process control, real-time monitoring, and performance diagnostics, making it a preferred choice for industrial automation specialist across India seeking reliable, high-precision control systems.

Secure Shipping & Domestic Market Reach

ALLEN BRADLEY PLC units are available for dispatching across the Indian market with secure shipping options. We ensure each unit is carefully packed for transportation and prompt delivery to your location via a reliable FOB Port. Samples are available upon request, enabling you to evaluate product performance before bulk purchases. Our commitment to efficient shipping and transparent logistics ensures quality PLCs reach you safely, optimizing your industrial automation projects with minimal downtime.

FAQs of ALLEN BRADLEY PLC:

Q: How does the ALLEN BRADLEY PLC benefit industrial automation applications?

A: The ALLEN BRADLEY PLC provides reliable process control, rapid response times under 1 ms, integrated diagnostic capabilities, and expandable I/O, making it ideal for complex automation and process control needs.Q: What is the process for programming and updating the PLC?

A: Programming is performed via RSLogix 500 software, while firmware updates are supported through dedicated ports, ensuring seamless operation and easy maintenance.Q: When should the integrated backup battery be checked or replaced?

A: The backup battery should be checked regularly as part of routine maintenance, especially if the PLC is used for critical data retention during power outages.Q: Where is this PLC best suited for installation?

A: It is best suited for installation on DIN Rail mounts within industrial panels, in manufacturing plants, process industries, and automated control rooms.Q: What are the main safety and protection features included?

A: The PLC features over/under voltage protection, error code diagnostics, and meets stringent safety standards (IEC/EN61131), ensuring secure and dependable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN-BRADLEY CAT 2711P-RP1 (2)

Storage Temperature : 20C to 70C

Voltage Protection : Builtin voltage protection circuitry

Input Voltage : 24 V DC

Working Temperature : 0C to 55C

Cooling Method : Passive cooling

Application : PanelView Plus 700/1000/1250/1500 HMI Modules

MICRO LOGIX 1500 1764-28BXB

Storage Temperature : 40C to 85C

Voltage Protection : Overvoltage Protection

Input Voltage : 24V DC

Working Temperature : 0C to 55C

Cooling Method : Natural Cooling

Application : Industrial Automation

ALLEN BRADLEY PLC 1764-24BWA B A

Storage Temperature : 25C to +70C

Voltage Protection : Yes (fuse protected)

Input Voltage : 120/240V AC

Working Temperature : 0C to +55C

Cooling Method : Natural convection

Application : Industrial automation, machine control

1746-IV16 ALLEN BRADLEY 1746 SLC 500

Storage Temperature : 40C 85C

Voltage Protection : Integrated circuit protection

Input Voltage : 24V DC

Working Temperature : 0C 60C

Cooling Method : None (Passive)

Application : Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry