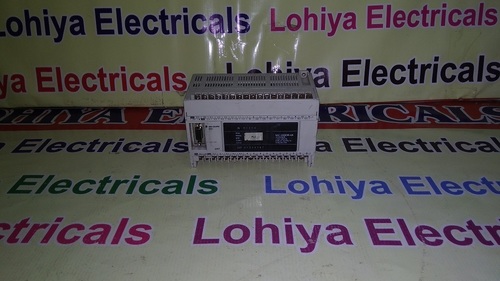

ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Specification

- Cooling Method

- Natural Air Cooling

- Power Factor

- >0.95

- Noise Level

- <60 dB

- Features

- Modular Design, High Reliability, Compact Size, Easy Installation

- Rated Current

- 1 A

- Output Type

- Relay / Transistor (depending on model)

- Output Current

- 1 A

- Power Supply

- AC Powered

- Rated Power

- 24 W

- Phase

- Single Phase

- Current Range

- 0.1 A to 1 A

- Working Temperature

- 0C to +55C

- Connector Type

- Screw Terminal

- Application

- Industrial Automation, Machine Control, Process Automation

- Operating Temperature

- 0C to +55C

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- 24 W

- Output Frequency

- 50/60 Hz

- Input Voltage

- 100-240 V AC

- Voltage Protection

- Overvoltage, Undervoltage Protection

- Efficiency

- 85%

- Material

- Industrial Grade Plastic Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to +85C

- Weight

- 350 g

- Response Time

- <1 ms (typical)

- Communication Ports

- RS232, RS485, Ethernet, USB (model specific)

- I/O Expansion

- Expandable up to 256 I/O points (model dependent)

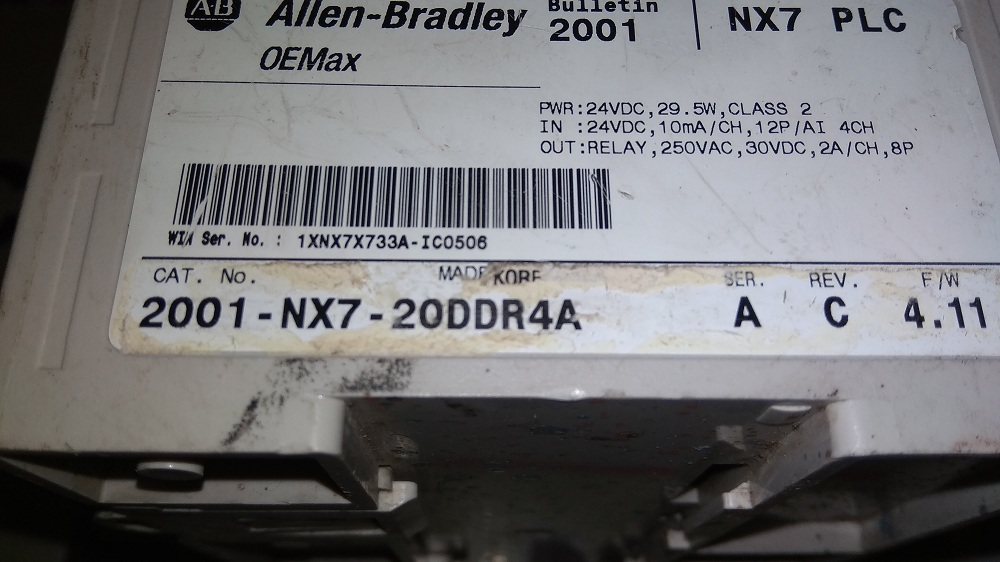

- Part Number

- PLC Series (e.g., MicroLogix, CompactLogix, ControlLogix depending on availability)

- Backup

- Battery backup for memory retention

- Enclosure Protection

- IP20

- Mounting Type

- DIN Rail Mounting

- Display Type

- LED status indicators

- Programming Language

- Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD)

- Memory Capacity

- Varies by model, typically 2KB-32KB

About ALLEN BRADLEY PLC

Versatile Usage & Application Scope

ALLEN BRADLEY PLCs are engineered for diverse industrial environments, serving as the core of automation across manufacturing, assembly lines, and process automation fields. Used extensively in machinery control, these PLCs grant commanding performance for system integration and automation enhancements. With exceptional flexibility, users can deploy these controllers in warehouse automation, food processing, packaging, and industrial robotics, ensuring unassailable process efficiency and reduced downtime.

Packaging, Export, and Delivery Details

Each ALLEN BRADLEY PLC is securely packaged to withstand long journeys, especially during domestic and global transport services. With a focus on durability, the packaging is designed to maintain product integrity until installation. Exported primarily via major Indian ports on FOB terms, these controllers reach international clients at the lowest price possible. The domestic market benefits from streamlined logistics for timely delivery and optimal supply chain performance.

FAQs of ALLEN BRADLEY PLC:

Q: How do I install the ALLEN BRADLEY PLC on a DIN rail?

A: Simply attach the PLC to the DIN rail by aligning it and snapping it securely in place. Ensure connections are made using the screw terminals as per the installation guide.Q: What are the key benefits of using ALLEN BRADLEY PLCs in industrial automation?

A: They provide high reliability, rapid response (<1 ms), modular expansion, robust voltage protection, and easy integration with a range of communication ports, making automation setups both efficient and scalable.Q: Where can ALLEN BRADLEY PLCs be commonly applied?

A: They are widely used in industrial automation, machine control, process automation, manufacturing lines, packaging, and robotic systems, offering commanding control over various applications.Q: What is the memory and I/O capacity for different PLC models?

A: Memory capacity varies from 2KB to 32KB, and I/O expansion supports up to 256 points, depending on the chosen model (MicroLogix, CompactLogix, or ControlLogix).Q: When should battery backup be considered for PLC memory?

A: Battery backup is essential when memory retention is critical during power failures, avoiding data loss in continuous or sensitive automation processes.Q: How does voltage protection enhance the reliability of these PLCs?

A: Advanced overvoltage and undervoltage protection safeguards internal circuits, ensuring unassailable operation and extended PLC lifespan, even in fluctuating industrial power environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

S200-ir8 S200-ir8

Product Type : S200ir8

Output Type : Single

Storage Temperature : 25C to +85C

Input Voltage : 220V AC

Power Supply : AC

Working Temperature : 10C to +60C

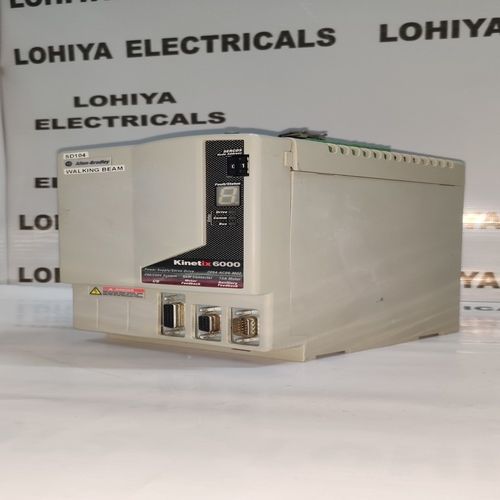

ALLEN BRADLEY 2094-AC09-M02 KINETIX 6000 INTEGRATED AXIS MODULE

Product Type : Integrated Axis Module

Output Type : Other, Digital servo drive outputs

Storage Temperature : 40C to 85C

Input Voltage : VM: 195264V AC, DC bus: 250670V DC

Power Supply : AC powered (195264V)

Working Temperature : 0C to 55C operating

1746-NIO4I ALLEN BRADLEY 1746 SLC 500

Product Type : Module for SLC 500 System

Output Type : Analog, Other

Storage Temperature : 40C to 85C

Input Voltage : 24VDC

Power Supply : External Power Supply Required

Working Temperature : 0C to 60C

SLC 1746 MODULE 1746-0B16 B

Product Type : SLC 1746 MODULE

Output Type : Other, Digital (Relay Output)

Storage Temperature : 40C to +85C

Input Voltage : 24V DC

Power Supply : 24V DC

Working Temperature : 0C to 60C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry