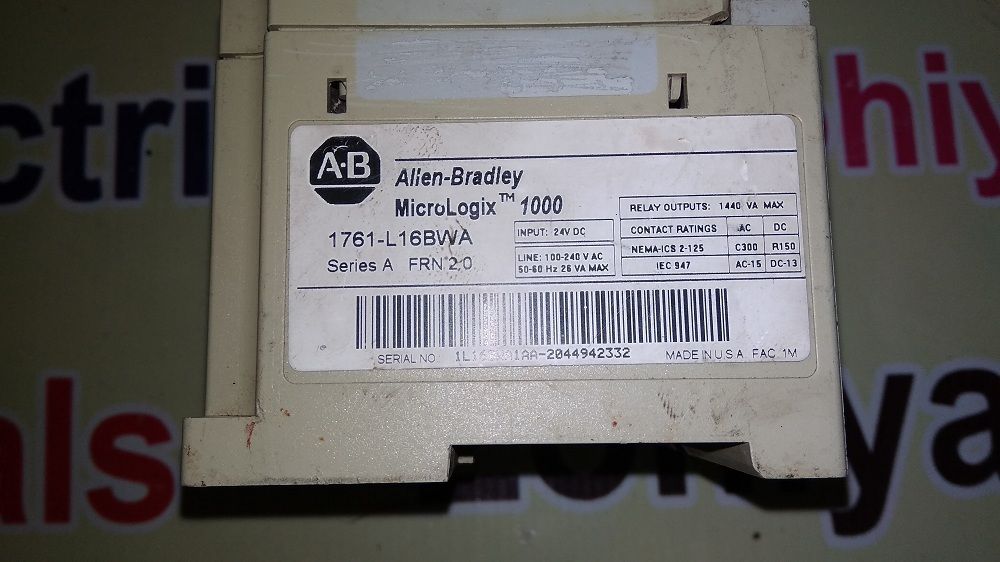

ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Specification

- Output Type

- Relay / Transistor / Analog

- Operating Temperature

- 0C to 60C

- Power Factor

- >0.95

- Output Current

- Depends on module, typically 2A to 8A

- Features

- Modular design, expandable, high speed processing, LED indicator

- Rated Current

- Variable by channel/module

- Phase

- Single Phase / Three Phase (depending on model)

- Power Supply

- AC/DC Universal

- Noise Level

- Low (<40 dB)

- Cooling Method

- Natural air cooling

- Rated Power

- Determined by specific module selection

- Current Range

- 0.1A to 8A (as per output module)

- Application

- Industrial automation, process control, machine automation

- Working Temperature

- 0C to 60C

- Connector Type

- Terminal block, removable screw type

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- Varies as per module configuration

- Output Frequency

- 50/60 Hz

- Input Voltage

- 100-240V AC / 24V DC

- Voltage Protection

- Overvoltage and undervoltage protection

- Efficiency

- High efficiency, typically >90%

- Material

- Industrial-grade ABS/Polycarbonate

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to 85C

- Weight

- Approximately 550 grams

- Expandable Modules

- Supported for various digital, analog, and communication modules

- Communication Ports

- Ethernet, RS232, RS485, USB, DeviceNet, Profibus (model-dependent)

- Analog Outputs

- 2 to 16 channels (with option modules)

- Protection Class

- IP20

- Memory Capacity

- Up to 2 MB user memory

- Standards Compliance

- CE, UL, cUL, RoHS

- Typical Response Time

- 1-5 ms based on application

- Digital Outputs

- 8 to 32 channels (expandable)

- Programming Software

- RSLogix / Studio 5000 / Connected Components Workbench

- Max I/O Points

- Up to 1024 (depending on controller series/model)

- Display

- LED status indicators

- Vibration Resistance

- 5g (10-150 Hz)

- Scan Time

- ~0.2 ms per Kstep

- Mounting Type

- DIN rail or panel mounting

- Digital Inputs

- 8 to 32 channels (expandable)

- Remote Access

- Supported via Ethernet/IP

- Analog Inputs

- 2 to 16 channels (with option modules)

- Battery Back-Up

- Yes (real-time clock and memory retention)

- Shock Resistance

- 10g (11 ms)

About ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Industrial Usage & Application

The ALLEN BRADLEY PLC is tailored for industrial automation, process control, and machine management. It excels in applications where precise monitoring and control of multiple inputs and outputs is required, including manufacturing plants and utility sectors. Implemented through modular expansion and reliable programming software, it offers flexible mounting (DIN rail/panel) and adapts to evolving automation needs. Users benefit from potent real-time response and seamless integration into complex industrial systems.

Domestic & Export Markets, Sample Policy of ALLEN BRADLEY PLC

ALLEN BRADLEY PLCs are shipped as prime goods across India and major international markets. We offer drop-off solutions for domestic clients and comprehensive export assistance for overseas partners. Our sample policy ensures you can try now before committing to large orders, with swift delivery and support. Every transaction guarantees secure packaging and tracking, reinforcing our commitment to reliability for both local and export distribution channels.

FAQs of ALLEN BRADLEY PLC:

Q: How do I expand the digital or analog channels on my ALLEN BRADLEY PLC?

A: You can expand digital and analog channels by integrating modular option units, allowing customization according to your application requirements. Follow the manufacturers guidelines for safe installation and configuration.Q: What is the typical response time and scan rate for ALLEN BRADLEY PLCs?

A: ALLEN BRADLEY PLCs offer scan times around 0.2 ms per Kstep and typical response times ranging from 15 ms, depending on your applications complexity and the specific controller model.Q: Where can ALLEN BRADLEY PLCs be used?

A: They are ideal for use in industrial automation, process control environments, and machine automation across manufacturing, utilities, and related sectors requiring robust, modular control systems.Q: When is remote access possible with ALLEN BRADLEY PLCs?

A: Remote access is supported at any time via Ethernet/IP communication ports, enabling you to monitor or program your PLC from a distance as long as the network is properly configured.Q: What is the benefit of having modular, expandable design in the PLC?

A: Modular and expandable design allows you to unlock flexibility for future upgrades, accommodate complex projects, and adapt the system to ever-changing industrial requirements without replacing the entire PLC.Q: How does the sample policy work when ordering ALLEN BRADLEY PLCs?

A: Our sample policy offers you the chance to try an ALLEN BRADLEY PLC before committing to bulk orders. Samples are shipped promptly with full guidance and support provided to evaluate product compatibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY SERVO DRIVE

Power Supply : AC

Cooling Method : Forced Air Cooling

Working Temperature : 0C to +55C

Connector Type : Screw Terminal

Application : Precision Motion Control, CNC Machines, Robotics, Packaging Machinery

Storage Temperature : 20C to +60C

ALLEN-BRADLEY 1394C-AM03

Power Supply : Electric

Cooling Method : Aircooled

Working Temperature : 0C to 50C

Connector Type : Standard

Application : Motion control systems

Storage Temperature : 20C to 85C

ALLEN BRADLEY KINETIX 6000 DRIVE 2094-SE02F-M00-S0

Power Supply : AC

Cooling Method : Natural Convection

Working Temperature : 0C to 50C

Connector Type : Integrated Ethernet

Application : Industrial Automation

Storage Temperature : 20C to 70C

ALLEN BRADLEY MODULE

Power Supply : External

Cooling Method : None

Working Temperature : 0C to 55C

Connector Type : Pin connector

Application : Industrial automation

Storage Temperature : 40C to 85C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry