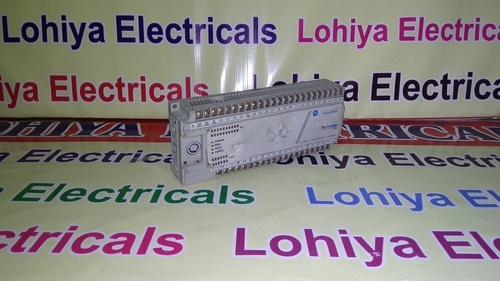

ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Specification

- Connector Type

- Screw Terminal

- Rated Current

- 2 A

- Features

- Modular Design, Expandable I/O, Ethernet Capability, LED Indicators, Diagnostics

- Power Factor

- >0.9

- Phase

- Single/Three Phase (Model dependent)

- Power Supply

- Integrated Power Supply

- Rated Power

- 24 W

- Output Current

- Max 2 A (Model dependent)

- Application

- Industrial Automation, Machine Control, Process Control

- Noise Level

- Low Noise Operation

- Current Range

- 0-2 A

- Cooling Method

- Natural Air Cooling

- Working Temperature

- 0C to +60C

- Operating Temperature

- 0C to +60C

- Output Type

- Digital & Analog

- Product Type

- Allen Bradley PLC (Programmable Logic Controller)

- Output Power

- 24 VDC

- Output Frequency

- 50/60 Hz

- Input Voltage

- 100-240 VAC

- Voltage Protection

- Overvoltage Protection

- Efficiency

- High Efficiency

- Material

- Industrial Grade Plastic and Metal

- Line Regulation

- 1%

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 1.5 kg

About ALLEN BRADLEY PLC

ALLEN BRADLEY PLC: Versatile Applications and Key Advantages

The ALLEN BRADLEY PLC shines in application surfaces such as industrial automation, process control, and machinery management. With its competitive advantagesincluding low noise operation, modular expandability, and robust diagnosticsit delivers superior performance in both digital and analog media. Expansion up to 512 I/O points and compatibility with top-tier automation software ensures seamless integration, making it a trusted choice for dynamic industries seeking pristine and reliable automation solutions.

Main Export Markets and Supply Chain Excellence

ALLEN BRADLEY PLC caters to global markets, with primary exports spanning Asia, Europe, and the Americas. Order processing is streamlined for timely shipping, with FOB options from major Indian ports. The company boasts substantial supply ability to meet large-scale demand, ensuring efficient transportation and careful valuation of each order. Reliable logistics support and responsive service further enhance the customer experience, making each transaction secure and professional.

FAQs of ALLEN BRADLEY PLC:

Q: How do I select the right ALLEN BRADLEY PLC model for my application?

A: Selection depends on your desired communication protocols, input/output needs, and system compatibility. Reviewing your automation and control requirements will help determine the ideal model.Q: What are the processes involved in installing this PLC?

A: Installation requires DIN rail mounting, connecting with screw terminals, and configuring through RSLogix 5000 or Studio 5000 programming software, followed by system and diagnostics setup.Q: Where can the ALLEN BRADLEY PLC be used effectively?

A: It is optimized for industrial automation, machine control, and process control in a range of sectors, including manufacturing, packaging, and utilities.Q: What benefits do LED status indicators and built-in diagnostics provide?

A: LED indicators and diagnostics enable swift troubleshooting, real-time status updates, and efficient system monitoring, reducing downtime and increasing productivity.Q: How does the SD card expansion support benefit system usage?

A: SD card expansion provides scalable memory for complex projects, simplifies data storage, and enhances configuration flexibility during project upgrades or troubleshooting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY MODULE

Power Supply : DC Supplied

Storage Temperature : 40C to 85C

Material : Industrialgrade Plastic and Metal

Phase : Single Phase

Connector Type : Screw Terminal/Pluggable Terminal Block

Features : Hotswappable, Plugandplay, LED Status Indicators

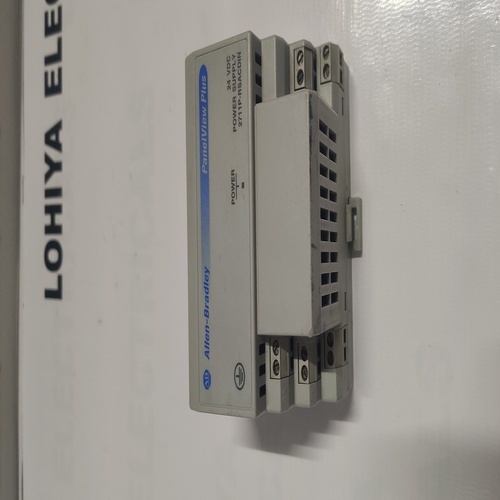

ALLEN-BRADLEY 2711P-RSACDIN POWER SUPPLY

Power Supply : DIN Rail Mount

Storage Temperature : 40C to 85C

Material : Plastic and Metal

Phase : Single Phase

Connector Type : Screw Terminal Block

Features : Compact Design, DIN Rail Mountable, LED Indicator, Protection Circuits

ALLEN-BRADLEY 1394C-SJT10-T-RL (2)

Power Supply : AC

Storage Temperature : 20C to 70C

Material : Durable Plastic

Phase : Single Phase

Connector Type : Standard

Features : Compact Design Reliable

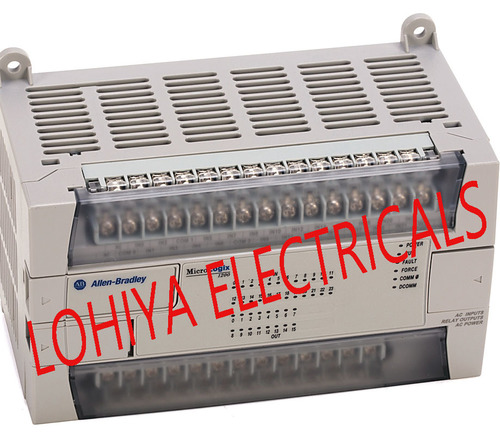

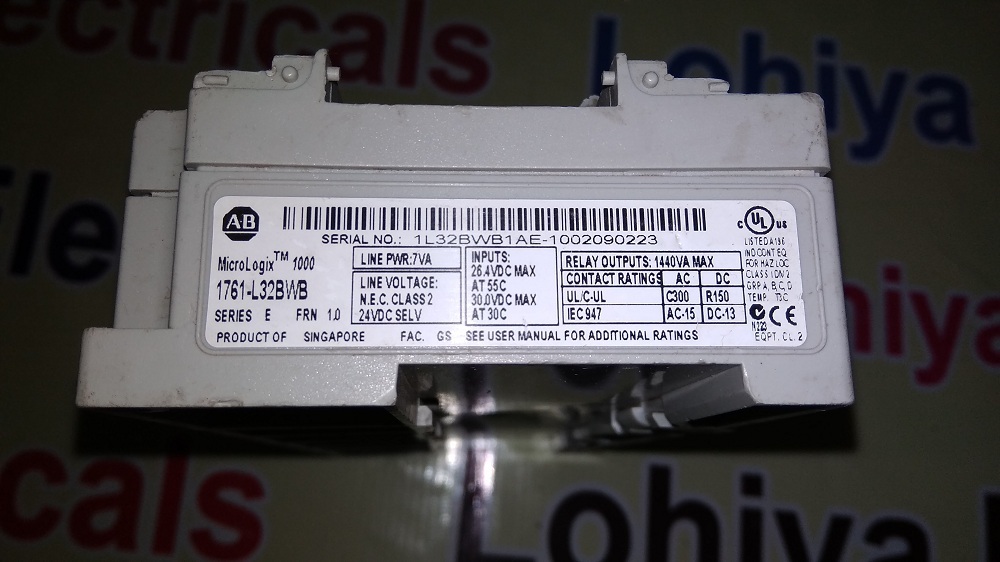

ALLEN BRADLEY MICROLOGIX 1200 PLC 1762-L24BWA

Power Supply : Builtin

Storage Temperature : 40C to 85C

Material : Plastic Housing

Phase : Single Phase

Connector Type : Terminal Block

Features : Builtin Data Logging Multiprotocol Communication

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry