ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Rated Current

- 2A

- Connector Type

- Screw Terminal, Removable Terminal Block

- Working Temperature

- 0C to 60C

- Features

- Hot Swap, Diagnostic LED, Removable Terminal Block, Overload Protection

- Output Current

- 2A per channel (typical, varies by module)

- Cooling Method

- Natural Air Cooling

- Current Range

- 0-2A (per channel)

- Rated Power

- Up to 48W (model dependent)

- Power Factor

- >0.9 (typical, active modules)

- Application

- Industrial Automation, Process Control, Machine Monitoring

- Noise Level

- < 50 dB

- Power Supply

- External, Redundant Power Supply Supported

- Phase

- Single and Three Phase Models Available

- Operating Temperature

- 0C to 60C

- Output Type

- Digital and Analog (depends on module model)

- Product Type

- ALLEN BRADLEY MODULE

- Output Power

- 24V DC, 2A (typical output ratings for PLC modules)

- Output Frequency

- 50/60 Hz (for AC modules)

- Input Voltage

- 24V DC, 120/240V AC (dependent on module type)

- Voltage Protection

- Input Overvoltage and Reverse Polarity Protection

- Efficiency

- Up to 90% (typical for switching modules)

- Material

- Flame-retardant Polycarbonate, Metal Shielding

- Line Regulation

- 1% (typical)

- Storage Temperature

- -40C to 85C

- Weight

- 0.2 to 0.5 kg (varies by module)

- Humidity Range

- 5% to 95% non-condensing

- Expansion Capability

- Supports Multiple Expansion Modules

- Isolation Voltage

- 1500V RMS for 1 min

- Compatibility

- Allen Bradley CompactLogix, ControlLogix PLCs

- Response Time

- < 1 ms (typical)

- Status Indicator

- LED Indications for Run, Fault, Input/Output Status

- Mounting Type

- DIN Rail Mounting

- Protection Class

- IP20

- Module Type

- Input/Output, Communication, Power Supply

- Programmable

- Yes, with applicable Allen Bradley Software

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE OFE2 BReliability and Safety

Designed for demanding environments, the ALLEN BRADLEY MODULE features flame-retardant polycarbonate construction, metal shielding, and overload protection for maximum safety. Its 1500V RMS isolation voltage and IP20 protection class ensure electrical safety and longevity even in rigorous industrial settings.

Flexible Integration

With mounting on DIN rails, compatibility with CompactLogix and ControlLogix PLCs, and support for multiple expansion modules, this module assures flexible integration into new or existing automation systems. It accommodates digital and analog signals as well as various voltage types, making it suitable for broad integration requirements.

User-Friendly Features

Equipped with LED indications for run, fault, and I/O status, removable terminal blocks, diagnostic LEDs, and natural air cooling, the module prioritizes ease-of-use and streamlined maintenance. The programmable nature via Allen Bradley Software empowers users to tailor performance to their application.

FAQs of ALLEN BRADLEY MODULE:

Q: How can I mount the ALLEN BRADLEY MODULE in my industrial setup?

A: The module is designed for DIN rail mounting, making installation quick and secure in standard control cabinets typically used in industrial automation environments.Q: What process should I follow to program the module?

A: Programming the ALLEN BRADLEY MODULE is achieved using applicable Allen Bradley Software, allowing custom logic and parameter settings for seamless operation within CompactLogix or ControlLogix PLC systems.Q: When should I use a module with both digital and analog output types?

A: Choose a module with both digital and analog outputs when your application requires a combination of on/off control and variable signal handling. This is ideal for mixed-process automation, such as machine monitoring or process control.Q: Where can I find information about compatibility with different PLCs?

A: This module is compatible with Allen Bradley CompactLogix and ControlLogix PLCs. Refer to the product manual or supplier datasheet for full details on supported PLC models and communication protocols.Q: What are the benefits of the modules hot swap and diagnostic LED features?

A: Hot swap capability allows you to replace or add modules without shutting down the system, minimizing downtime. Diagnostic LEDs offer at-a-glance status for run, fault, and input/output, simplifying troubleshooting and maintenance.Q: How does the module ensure protection against electrical faults?

A: Featuring input overvoltage and reverse polarity protection, as well as overload protection and line regulation of 1%, the module is built to safeguard connected circuits and maintain stable performance even in the event of electrical irregularities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

SLC 1746 MODULE 1746-OBP16 C

Connector Type : Removable terminal block

Product Type : SLC 1746 Output Module

Working Temperature : 0C to 60C

Weight : Approx. 170g

Material : Plastic and Electronic Components

Features : 16point Output, LED indicators, Removable terminal block

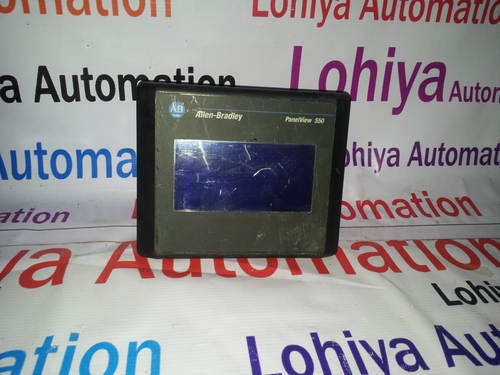

ALLEN-BRADLEY CAT 2711-T5A5L1

Connector Type : Ethernet/IP Serial

Product Type : PanelView Terminal

Working Temperature : 0C to 55C

Weight : Approx. 1 kg

Material : Plastic and Glass

Features : 5.5inch Monochrome Display Touchscreen Ethernet Port

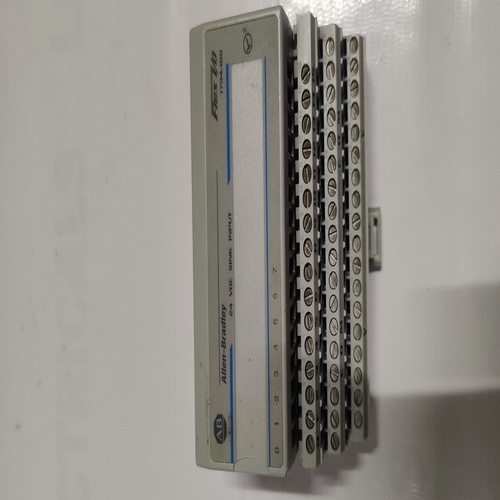

ALLEN-BRADLEY 1794-IB8 MODULE

Connector Type : Removable Terminal Block

Product Type : Digital Input Module

Working Temperature : 20C to +55C

Weight : Approx. 75 g

Material : Polycarbonate (Housing)

Features : Removable Terminal Block, LED Indicators, Compact Design

SLC 1746 MODULE 1746-HSCE A

Connector Type : Card Edge Connector

Product Type : SLC 1746 HighSpeed Counter Module

Working Temperature : 0C to 50C

Weight : Approx. 200g

Material : Plastic and Electronic Components

Features : HighSpeed Counter Module

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry