ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Rated Power

- Dependent on Module Type

- Current Range

- 500 mA (typical)

- Application

- Industrial Automation, Machine Control

- Output Type

- Digital/Analog (Model Dependent)

- Rated Current

- Typical 0.5 - 2 A (model specific)

- Phase

- Single Phase

- Power Supply

- 24V DC Input

- Features

- Modular Design, DIN Rail Mounting, LED Indicator, Hot Swap Capable, Compact Size, Wide Compatibility

- Working Temperature

- 0C to 60C

- Power Factor

- > 0.95

- Cooling Method

- Natural Air Cooling

- Operating Temperature

- 0C to 60C

- Connector Type

- Screw Terminal, Plug-in Connectors

- Noise Level

- Low (<45 dB)

- Product Type

- Programmable Logic Controller (PLC) Module

- Input Voltage

- 24 V DC

- Voltage Protection

- Overvoltage, Reverse Polarity

- Efficiency

- High Efficiency (>90%)

- Material

- Industrial-grade Plastic, Metal

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to 85C

- Weight

- Approx. 200 - 350 g

- LED Indicators

- Status and Fault LEDs

- Model Series

- 1769, 1756, or other Allen Bradley PLC Series

- Max I/O Points

- Varies by module (8/16/32/64)

- Programmable Memory Type

- Flash/EEPROM (model specific)

- Communication Interface

- RS232/RS485, Ethernet (varies by model)

- Isolation Voltage

- 500V RMS for 1 minute (channel to ground)

- Relative Humidity

- 5% to 95% non-condensing

- Dimensions

- 118 x 35 x 87 mm (HxWxD, approx.)

- Mounting Type

- DIN Rail Mount

- Response Time

- < 1 ms (typical)

- Protection Class

- IP20

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE IKCRobust Communication and Flexible Integration

Supporting RS232/RS485 and Ethernet interfaces (varies by model), Allen Bradley Modules easily integrate into modern industrial automation systems. The combination of screw terminals and plug-in connectors facilitates seamless installation and reliable signal transmission, enabling compatibility with both legacy and contemporary devices.

Built for Reliability and Efficiency

With an IP20 protection class and precision-crafted from industrial-grade plastic and metal, the modules ensure enduring performance. Overvoltage and reverse polarity protection, along with a high power factor and efficiency above 90%, allow for safe and energy-conscious operation in challenging industrial settings.

User-Centric Features for Simplified Maintenance

LED indicators for status and fault alerts, hot-swap capability, DIN rail mounting, and natural air cooling contribute to an easy-to-maintain solution. The compact design permits optimal use of control cabinet space while supporting a wide range of applications in process control and machine management.

FAQs of ALLEN BRADLEY MODULE:

Q: How can I install the Allen Bradley Module in my control system?

A: Installation is straightforward using the DIN rail mount system. Simply secure the module onto the rail, connect the power supply (24V DC input), and use screw terminals or plug-in connectors for signal wiring. Always follow the specific wiring diagrams and safety guidelines provided by Allen Bradley for your model.Q: What communication interfaces are available with this module?

A: Depending on the model, the module may support RS232/RS485 or Ethernet interfaces. This versatility ensures seamless integration with various industrial networks and devices, making it suitable for both legacy systems and newer automated setups.Q: When should I use the LED indicators on the module?

A: LED indicators are designed to provide real-time status and fault diagnostics. Use them during startup, operation, or maintenance to quickly assess functional states and respond to faults, which helps minimize system downtime and streamline troubleshooting.Q: Where is this Allen Bradley Module most effectively utilized?

A: The module excels in industrial automation and machine control environments. It is commonly used in control panels, production lines, and machinery monitoring systems, benefiting applications that require robust connectivity, fast response, and reliable performance.Q: What is the benefit of the modules hot swap capability?

A: Hot swap capability allows you to replace or add modules without shutting down the entire system. This feature reduces operational interruptions, increases uptime, and simplifies system expansion or maintenance, which is particularly advantageous in high-demand industrial settings.Q: How does the module ensure operational safety and reliability?

A: The module features overvoltage and reverse polarity protection, rigorous isolation voltage (500V RMS), and is constructed from durable materials. Its wide operating temperature range and high efficiency further ensure consistent and safe performance under demanding industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY MODULE

Product Type : Automation Module

Rated Power : 240W

Efficiency : High

Current Range : 010A

Line Regulation : 5%

Application : Industrial Automation

NX7 PLC

Product Type : NX7 PLC

Rated Power : 12W

Efficiency : >85%

Current Range : 0.1A to 0.5A

Line Regulation : 0.5%

Application : Industrial Automation, Process Control, Machine Automation

SLC 1746 MODULE 1746-0A16 D

Product Type : SLC 1746 MODULE 17460A16 D

Rated Power : Dependent on load and channel usage

Efficiency : Highoutput reliability for industrial applications

Current Range : 02A per channel

Line Regulation : Stable output under line fluctuations

Application : Programmable Logic Controller (PLC) applications

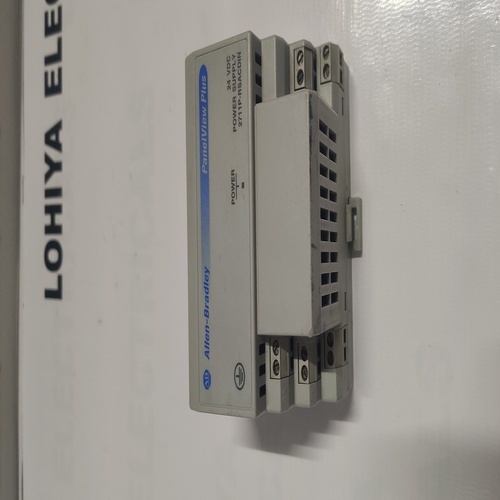

ALLEN-BRADLEY 2711P-RSACDIN POWER SUPPLY

Product Type : Power Supply Unit

Rated Power : 50 W

Efficiency : 85% (typical)

Current Range : 02.1 A

Line Regulation : 1%

Application : PanelView Plus Terminals, Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry