ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Current Range

- 0-2A

- Cooling Method

- Natural Convection

- Power Supply

- External Power Supply

- Features

- Hot-Swap Capability, Diagnostics LED, DIN Rail Mount

- Phase

- Single Phase

- Application

- Industrial Automation, Process Control

- Output Type

- Digital

- Rated Power

- 48W

- Power Factor

- >0.98

- Operating Temperature

- 0C to +60C

- Rated Current

- 2A

- Output Current

- 2A max

- Connector Type

- Removable Terminal Block

- Noise Level

- <50 dB

- Working Temperature

- 0C to +60C

- Product Type

- Control System Module

- Output Power

- 24V DC, 2A

- Output Frequency

- 50/60 Hz

- Input Voltage

- 120/240V AC

- Voltage Protection

- Overvoltage, Undervoltage, Short Circuit Protection

- Efficiency

- Up to 92%

- Material

- Industrial Grade Thermoplastic and Metal

- Line Regulation

- <0.5%

- Storage Temperature

- -40C to +85C

- Weight

- 0.72 kg

- Life Expectancy

- >100,000 operations

- Status Indicators

- LEDs For Output State

- Response Time

- 10 ms

- Communication Interface

- Backplane

- System Compatibility

- SLC 500 Series

- Mounting Type

- DIN Rail

- Protection Class

- IP20

- Model Number

- 1746-OW16

- Isolation Voltage

- 1500V AC

- Dimensions (HxWxD)

- 140 mm x 35 mm x 87 mm

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE IBSeamless SLC 500 Integration

The 1746-OW16 module is specifically designed to fit and function flawlessly with Allen Bradleys SLC 500 Series PLC systems. Quick installation on a DIN rail and a standardized backplane interface make expansion and replacements effortless, ensuring minimal downtime and smooth system upgrades.

Advanced Protection and Diagnostic Features

With integrated overvoltage, undervoltage, and short circuit protection, this module prioritizes system safety and longevity. Onboard diagnostics LEDs for output status offer immediate feedback on module operation, aiding fast troubleshooting and reducing the need for in-depth intervention.

Efficient and Reliable Performance

Delivering up to 92% efficiency and line regulation below 0.5%, the 1746-OW16 operates in diverse conditions with a wide -40C to +85C storage and 0C to +60C working temperature range. Its natural convection cooling and industrial-grade enclosure ensure consistent, reliable digital output for automation needs.

FAQs of ALLEN BRADLEY MODULE:

Q: How is the ALLEN BRADLEY 1746-OW16 module installed in an automation system?

A: The 1746-OW16 module is designed for DIN rail mounting and connects easily into an SLC 500 Series system via the standard backplane interface. Installation requires attaching the module to the rail, connecting power through a removable terminal block, and configuring it in your SLC hardware setup.Q: What types of protection does the 1746-OW16 module offer during operation?

A: This module provides robust protection against overvoltage, undervoltage, and short circuits, ensuring operational safety and protecting both the module and connected equipment from electrical hazards.Q: When should the diagnostics LEDs be checked on this module?

A: You should check the output state LEDs during system start-up, troubleshooting, or routine maintenance to monitor operational status and quickly identify any output issues without interrupting the industrial process.Q: Where is the 1746-OW16 module typically used?

A: This module is widely utilized in industrial automation and process control environments across manufacturing centers, assembly lines, and in applications where dependable digital output control is essential.Q: What benefits does the hot-swap capability offer?

A: Hot-swap capability allows you to replace or add the module without powering down your entire system, minimizing downtime and maintaining productivity during maintenance or upgrades.Q: How does the module maintain efficient performance under varying load conditions?

A: With up to 92% efficiency, a power factor greater than 0.98, and line regulation below 0.5%, the module ensures stable operation and consistent output even when input voltage fluctuates or loads change.Q: What materials enhance the durability of the 1746-OW16 module?

A: The module is constructed using industrial-grade thermoplastic and metal, providing robust mechanical protection and ensuring long service life even in demanding working environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY INPUT OUTPUT MODULE 1771-IBD

Operating Temperature : 0C to 60C

Product Type : Digital Input Module

Cooling Method : Natural convection

Power Supply : Supplied via PLC backplane

Features : 32 point, isolated inputs, LED status display, removable terminal block

Application : PLC systems, factory automation, process control

ALLEN BRADLEY PLC

Operating Temperature : 0C to +60C

Product Type : Programmable Logic Controller (PLC)

Cooling Method : Passive (aircooled)

Power Supply : Builtin or external power supply modules (AC/DC)

Features : Modular design, expandable I/O, Ethernet/IP, ControlNet, DeviceNet support

Application : Industrial automation, process control, machine control

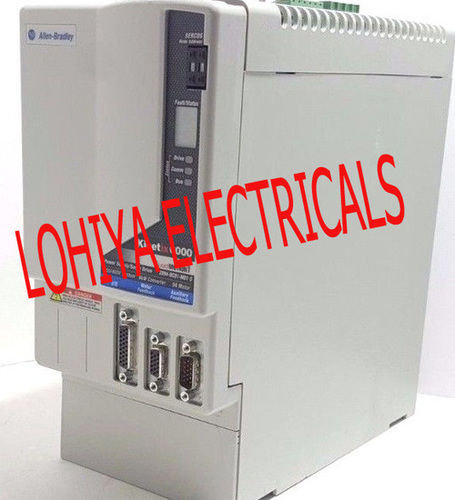

ALLEN BRADLEY ULTRA 3000 DRIVE 2098-DSD-HV0100-SE

Operating Temperature : 0C to 50C

Product Type : Servo Drive

Cooling Method : Air Cooling

Power Supply : AC

Features : Feedback options Compact design

Application : Motion Control

ALLEN BRADLEY KINETIX 6000 DRIVE 2094-BC01-M01

Operating Temperature : 0C to 50C

Product Type : Servo drive

Cooling Method : Air cooling

Power Supply : AC Power Supply

Features : Scalable multiaxis drive systems

Application : Industrial motion control

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry