ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Noise Level

- Low (Electromagnetic interference minimized)

- Operating Temperature

- 0C to +60C

- Output Type

- Digital/Analog options

- Working Temperature

- 0C to +60C

- Cooling Method

- Natural air cooling

- Phase

- Single Phase or Multi-Phase (model dependent)

- Connector Type

- Screw/Removable terminal block

- Features

- Hot Swap Support, Diagnostic LED, Removable Terminal Block

- Power Supply

- Field power and backplane power supported

- Application

- Industrial Automation, Process Control

- Product Type

- Module

- Input Voltage

- 24V DC / 120-240V AC (depending on model)

- Voltage Protection

- Overvoltage protection available

- Material

- Industrial grade components, ABS/Polycarbonate enclosure

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 200-450g (varies with model)

- Response Time

- < 1 ms (typical for digital modules)

- Dimensions

- Dimensions vary by module; e.g., 118 x 35 x 87 mm (LxWxH)

- Isolation Voltage

- 1500V AC (field to backplane)

- IP Rating

- IP20

- Model Series

- 1769, 1734, 1756, or similar CompactLogix/ControlLogix series (model specific)

- Mounting Type

- DIN Rail/Panel Mount

- Communication Interface

- Ethernet/IP, DeviceNet, ControlNet, or Backplane (model specific)

- Compatibility

- Compatible with PLC and I/O platforms

- Status Indicators

- Module Status, Channel Status LEDs

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE IACVersatile Industrial Automation

The ALLEN BRADLEY MODULE range offers unmatched adaptability, enabling configuration for digital or analog input/output applications. Its compatibility with numerous PLC and I/O platforms means seamless installation and operation in both legacy and modern systems. Support for field power, backplane power, and various communication interfaces allows users to tailor the module to specific industrial needs, maximizing productivity and reliability across process automation scenarios.

Robust Construction & Reliable Performance

Manufactured using durable ABS/polycarbonate enclosures and premium components, these modules can withstand challenging industrial conditions. Their excellent isolation voltage and overvoltage protection safeguard sensitive electronics, while diagnostic LED indicators and hot swap support ensure minimal downtime and straightforward maintenance. The operating temperature range of 0C to 60C and IP20 rating make them well-suited to a wide range of industrial environments.

FAQs of ALLEN BRADLEY MODULE:

Q: How do I select the appropriate ALLEN BRADLEY MODULE model for my application?

A: Start by identifying your required input/output type (digital or analog), mounting preference (DIN rail or panel), and desired communication interface (Ethernet/IP, DeviceNet, ControlNet, or Backplane). Ensure the models voltage compatibility and dimensions fit your control panel, and confirm PLC or I/O platform compatibility. Consult model specifications and datasheets for precise selection.Q: What are the benefits of using ALLEN BRADLEY MODULES with hot swap and diagnostic LED features?

A: Hot swap support enables modules to be replaced or added without system shutdown, reducing downtime. Diagnostic LEDs provide real-time status of modules and channels, allowing for quick troubleshooting and enhanced system reliability, especially valuable in industrial automation processes requiring high uptime.Q: When should I use a digital module versus an analog module?

A: Use digital modules for applications that require simple on/off or discrete-state control, such as switching devices or monitoring binary sensors. Choose analog modules for processes needing measurement and control of variable signals, like temperature, pressure, or flow, to provide precise regulation and feedback.Q: Where can ALLEN BRADLEY MODULES be installed and in what types of environments do they operate effectively?

A: These modules are suitable for industrial environments such as manufacturing plants, process control rooms, and automation suites. Their rugged construction, IP20 rating, and wide temperature tolerance make them effective in controlled indoor settings where protection from direct moisture and excessive dust is maintained.Q: What is the installation process for DIN rail or panel mounting these modules?

A: To mount on a DIN rail, simply snap the module into place and secure it according to the installation guidelines. For panel mounting, attach using recommended screws and mounting plates. Connect power, communication, and I/O wiring via screw or removable terminal blocks, ensuring adherence to wiring and safety standards.Q: How does the module ensure safe operation and protect connected devices?

A: With a robust isolation voltage of 1500V AC field to backplane and integrated overvoltage protection, these modules safeguard both internal electronics and connected field devices. This minimizes risks associated with electrical surges, noise, and ground loops, ensuring long-term system safety and stability.Q: What advantages do the Ethernet/IP, DeviceNet, and ControlNet interfaces provide?

A: These communication protocols ensure fast, reliable, and scalable integration within industrial networks. Ethernet/IP allows for high-speed data exchange and remote diagnostics, while DeviceNet and ControlNet facilitate efficient control and monitoring of distributed devices, making them ideal for complex automation setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY MODULE

Output Type : Other, Digital & Analog (model dependent)

Operating Temperature : 20C to 60C

Weight : Approx. 250g

Rated Current : 2A

Output Current : 2A (model specific)

Cooling Method : Natural Air Cooling

ALLEN-BRADLEY-2001-nx7-28edr

Output Type : DC

Operating Temperature : 050C

Weight : 1kg

Rated Current : 10A

Output Current : 10A

Cooling Method : Passive cooling

ALLEN-BRADLY POWER SUPPLY 1771 KA2

Output Type : DC Output, Other

Operating Temperature : 0C to 50C

Weight : 0.5kg

Rated Current : 2A

Output Current : 2A

Cooling Method : Natural Convection

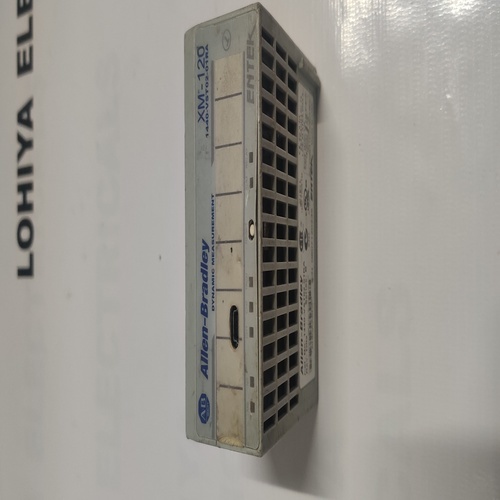

ALLEN BRADLEY XM-120 1440-VST02-01RA MODULE

Output Type : Other, Digital Relay, 420 mA Analog Output

Operating Temperature : 20C to 65C

Weight : Approx. 250g

Rated Current : 0.2 A (input supply current max.)

Output Current : 420 mA

Cooling Method : Natural Air Cooling

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry