ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Noise Level

- Low

- Operating Temperature

- 0C to 60C

- Application

- Industrial Automation, PLC Systems

- Features

- Hot Swap, Diagnostics LED, Compact Design

- Power Supply

- 24V DC

- Working Temperature

- 0C to 60C

- Phase

- Single/Three Phase Compatible

- Cooling Method

- Natural Air Cooling

- Output Type

- Digital/Analog

- Power Factor

- >0.95

- Connector Type

- Plug-in Terminal

- Product Type

- ALLEN BRADLEY MODULE

- Output Frequency

- 50/60 Hz

- Input Voltage

- 24V DC

- Voltage Protection

- Overvoltage Protection Included

- Efficiency

- High Efficiency

- Material

- Industrial Grade Plastic and Metal

- Line Regulation

- 1%

- Storage Temperature

- -40C to 85C

- Weight

- Approx. 200g

- Compatibility

- Compatible with Allen Bradley PLC Control Systems

- Module Type

- I/O Module (Specific model may vary)

- Mounting Type

- DIN Rail Mount

- Dimensions

- 118 x 35 x 87 mm (L x W x H)

- LED Indicators

- Status and Diagnostics

- Response Time

- <2 ms

- Communication Protocol

- Ethernet/IP, DeviceNet

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE IBD/DAdvanced Communication Features

Equipped with Ethernet/IP and DeviceNet protocols, the ALLEN BRADLEY I/O Module provides reliable, high-speed connectivity essential for modern industrial networks. Compatibility with Allen Bradley PLC systems ensures smooth data exchange and process coordination, enhancing overall operational efficiency.

Efficient and Durable Design

This module combines high-performance components including quick response times and low noise operation within a compact, DIN rail-mountable enclosure. The use of industrial-grade plastic and metal guarantees durability, while natural air cooling and overvoltage protection ensure safe and continuous function in rigorous environments.

User-Friendly Installation and Operation

With plug-in terminals, diagnostic LED indicators, and hot swap support, the module is designed for easy installation, maintenance, and troubleshooting. Its compact size streamlines integration into control panels, making it a practical choice for system upgrades or new automation projects.

FAQs of ALLEN BRADLEY MODULE:

Q: How does the ALLEN BRADLEY I/O Module connect to control systems?

A: The module utilizes Ethernet/IP and DeviceNet communication protocols, allowing for secure and efficient integration with compatible Allen Bradley PLC control systems. This connectivity ensures seamless data transmission and process coordination.Q: What is the recommended process for mounting and installing the module?

A: Installation is straightforward with DIN rail mounting and plug-in terminal connectors. Simply secure the module on the rail inside your control panel, connect necessary wiring following the manufacturers guidelines, and verify LED diagnostic indicators for correct setup.Q: Where is the ALLEN BRADLEY I/O Module best utilized?

A: This module is ideal for industrial automation applications such as PLC system expansion, process monitoring, and precise machine control, especially in environments demanding quick response times, low noise, and high efficiency.Q: What are the benefits of LED status and diagnostics indicators?

A: The diagnostic LEDs readily display operational status and help identify any faults or malfunctions, enabling quick troubleshooting and minimizing system downtime during regular operation or maintenance.Q: When is hot swapping supported, and how does it benefit system maintenance?

A: Hot swap capability allows you to replace the module without shutting down the entire system, providing valuable flexibility during maintenance or unexpected repairs, and significantly reducing operational downtime.Q: What voltage protection features are included in the module?

A: The module integrates robust overvoltage protection to safeguard against electrical surges, ensuring reliable performance and protecting both the module and connected PLC systems.Q: How does the compact design enhance the usage experience?

A: Measuring only 118 x 35 x 87 mm and weighing approximately 200g, the compact design enables efficient use of panel space and offers easy handling during installation and upgrades, making it a versatile choice for diverse industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

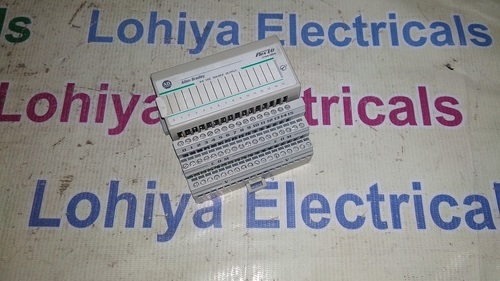

ALLEN BRADLEY PLC 1794-OB16

Connector Type : Removable Terminal Block

Product Type : PLC Digital Output Module

Material : Plastic, Electronic components

Working Temperature : 0 to 55C

Power Supply : 24V DC nominal

Features : Removable terminal block, LED status indicators

ALLEN BRADLEY 2093-AC05-MP5 KINETIX 2000 INTERGRATED AXIS MODULE

Connector Type : Screw terminal, removable connector

Product Type : Integrated Axis Module

Material : Rugged industrial enclosure

Working Temperature : 0C to 50C

Power Supply : 230V AC, 3phase

Features : Integrated safety, compact size, diagnostic LEDs, highspeed communication

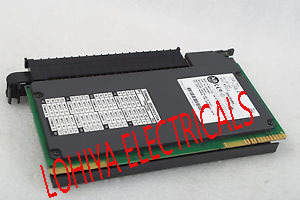

SLC 1746 MODULE 1746-NI04V

Connector Type : Removable Terminal Block

Product Type : SLC 1746 MODULE

Material : Plastic, Electronics

Working Temperature : 0C to 60C (32F to 140F)

Power Supply : 24V DC (From Backplane)

Features : 4 Isolated Analog Outputs, Removable Terminal Block, Diagnostics LEDs, Hot Swap Support

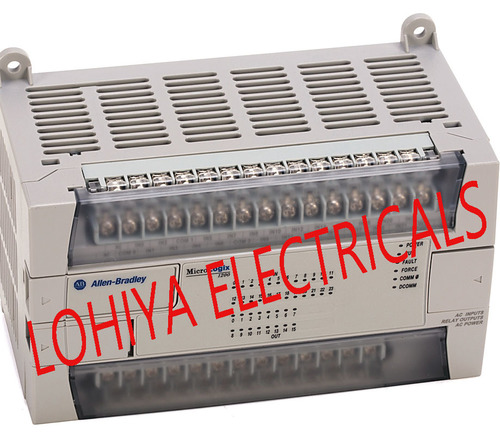

ALLEN BRADLEY MICROLOGIX 1200 PLC 1762-L40AWAR

Connector Type : Screw Terminal

Product Type : Programmable Logic Controller (PLC)

Material : Plastic Housing

Working Temperature : 0C to 55C

Power Supply : External

Features : MicroLogix 1200 Compact PLC Digital and Analog I/O

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry