ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE Specification

- Application

- PLC Automation Systems, Factory Automation, Industrial Process Control

- Current Range

- 00.5A

- Rated Current

- 0.5A

- Output Type

- Discrete/Digital

- Output Current

- 0.5A

- Phase

- Single Phase

- Connector Type

- Screw Terminal Connectors

- Power Factor

- >0.95

- Working Temperature

- 0C to 60C

- Cooling Method

- Natural Air Cooling

- Rated Power

- 12W

- Power Supply

- External AC Supply

- Operating Temperature

- 0C to 60C

- Noise Level

- Low Noise Operation

- Features

- DIN Rail Mounting, Compact Design, LED Status Indicator, Plug-in Connections

- Product Type

- Automation Control Module

- Output Power

- 24V DC, 0.5A

- Output Frequency

- 50/60 Hz

- Input Voltage

- 120/240V AC

- Voltage Protection

- Overvoltage Protection Included

- Efficiency

- High Efficiency

- Material

- Industrial Grade Plastic and Metal

- Line Regulation

- 1%

- Storage Temperature

- -40C to 85C

- Weight

- Approx. 300g

- Signal Type

- Digital (24V Logic)

- Approval Standards

- IEC/EN 61131-2

- LED Indicators

- Power, Status, Fault

- Lifetime (MTBF)

- >100,000 hours

- Mounting Type

- DIN Rail

- Isolation Voltage

- 1500V AC (Input/Output)

- Expansion Capability

- Modular, Supports Additional I/O

- Compatible Controllers

- Allen Bradley MicroLogix, ControlLogix, CompactLogix Series

- Response Time

- <10 ms

- Communication Interface

- Standard Fieldbus Support

- Dimensions

- 120 mm x 35 mm x 87 mm

- Protection Class

- IP20

About ALLEN BRADLEY MODULE

ALLEN BRADLEY MODULE IBD BVersatile Digital Signal Integration

This module handles discrete 24V digital signals, ensuring reliable performance in diverse industrial automation scenarios. Its high isolation voltage (1500V AC) safeguards input and output operations, while support for standard fieldbus communication enables seamless connectivity across automation networks.

Robust Industrial Protection

Featuring overvoltage protection, an IP20 rating, and compliance with IEC/EN 61131-2 standards, the module is built for safety and durability in demanding factory environments. Its housing uses industrial-grade plastic and metal for long-term resilience, and the natural air cooling system maintains optimal operation without added noise.

Effortless Expansion and Monitoring

The modular design allows for easy expansion and integration of additional I/O modules. LED indicators for power, status, and fault facilitate straightforward system diagnostics, ensuring real-time monitoring and improved maintenance. Plug-in connections and screw terminal connectors simplify installation and upgrades.

FAQs of ALLEN BRADLEY MODULE:

Q: How do I mount the ALLEN BRADLEY module in my control panel?

A: The module features a DIN rail mounting system, enabling quick and secure installation onto standard DIN rails found in industrial control panels. This design streamlines both initial setup and future module replacements or expansions.Q: What types of controllers are compatible with this digital module?

A: This module is compatible with Allen Bradley MicroLogix, ControlLogix, and CompactLogix series controllers, allowing flexible use across a range of PLC-based automation environments.Q: When should I consider expanding the modules I/O capacity?

A: Expansion is recommended when additional input or output channels are required for new sensors, actuators, or process points. Thanks to its modular architecture, additional modules can be plugged in easily as system demands grow.Q: Where can the module be used safely within an industrial setup?

A: The module is designed for factory automation and industrial process control environments. Its rated IP20 protection and approval to IEC/EN 61131-2 ensure safe operation outdoors or in protected settings, but it should not be exposed to moisture or corrosive atmospheres.Q: What is the process for diagnosing faults using the built-in LED indicators?

A: LED indicators provide real-time feedback on power, status, and faults. In the event of a fault, the corresponding LED will illuminate, alerting operators to issues that can then be addressed through system diagnostics or module replacement.Q: How does this module benefit industrial automation systems?

A: It offers rapid response times (<10 ms), high reliability (MTBF >100,000 hours), robust electrical isolation, and low noise operation. These features collectively enhance system performance, reliability, and safety in complex automation scenarios.Q: What should I know about the modules operating environment and electrical requirements?

A: This module operates on an external AC supply (120/240V AC), within 0C to 60C ambient temperature limits and 00.5A current range. Its high efficiency and power factor (>0.95) help reduce energy consumption and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN-BRADLEY Altra3000

Working Temperature : 10C to 50C

Application : Industrial Automation

Product Type : Servo Drive

Weight : 2.5 kg

Voltage Protection : Overvoltage Protection

Operating Temperature : 10C to 50C

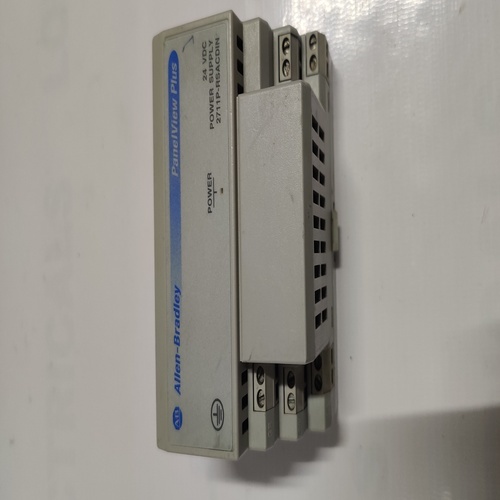

ALLEN-BRADLEY 2711P-RSACDIN POWER SUPPLY MODULE

Working Temperature : 0C to 55C

Application : For PanelView Plus Terminals and Machine Interfaces

Product Type : Power Supply Module

Weight : 0.35 kg

Voltage Protection : Overvoltage, Overload, Short Circuit Protection

Operating Temperature : 0C to 55C

ALLEN BRADLEY POWER SUPPLY

Working Temperature : 25C to 70C

Application : Electrical power systems

Product Type : Power Supply Unit

Weight : Lightweight

Voltage Protection : Overvoltage undervoltage and short circuit protection

Operating Temperature : 25C to 70C

ALLEN BRADLEY MICROLOGIX 1400 PLC

Working Temperature : 0C to 55C

Application : Industrial Automation

Product Type : Programmable Logic Controller (PLC)

Weight : Approximately 1.5 kg

Voltage Protection : Surge Protection

Operating Temperature : 0C to 55C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry