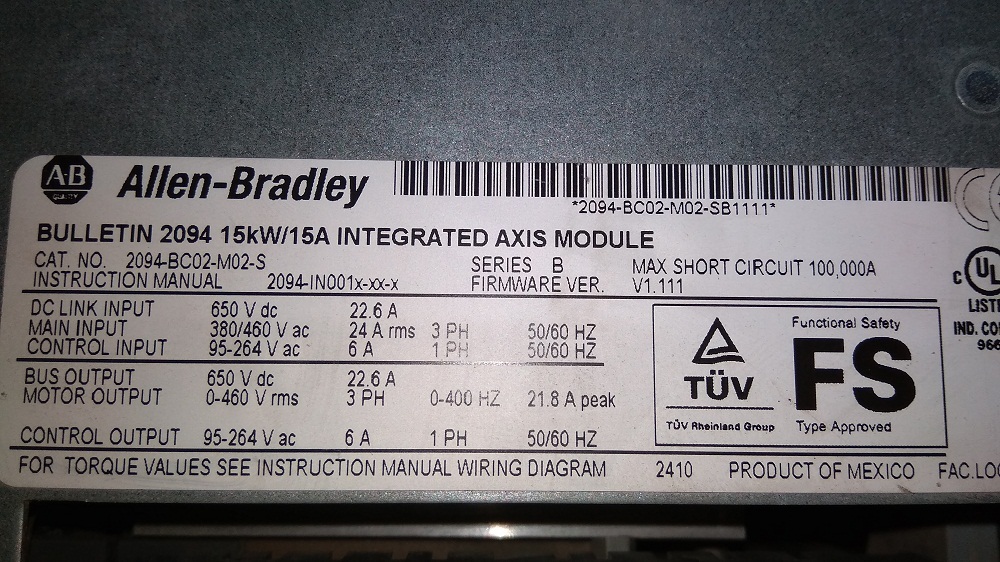

ALLEN BRADLEY INTEGRATED AXIS MODULE

ALLEN BRADLEY INTEGRATED AXIS MODULE Specification

- Connector Type

- Screw Terminal, Pluggable Connectors

- Working Temperature

- 0C to 55C

- Features

- Integrated Safe Torque-Off (STO), Compact Design, Easy Mounting, Diagnostics LED

- Cooling Method

- Forced Air Cooling

- Output Current

- 7.0 A

- Rated Current

- 7.0 A

- Operating Temperature

- 0C to 55C

- Noise Level

- < 45 dB

- Rated Power

- 1.5 kW

- Output Type

- Digital/PWM

- Power Supply

- AC

- Phase

- Three Phase

- Application

- Industrial Motion Control, Automation, Robotics

- Current Range

- 57 A

- Power Factor

- >0.95

- Product Type

- Integrated Axis Module

- Output Power

- 1.5 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 200-240 VAC

- Voltage Protection

- Overvoltage/Undervoltage Protection

- Efficiency

- Up to 97%

- Material

- Metal, Plastic Housing

- Line Regulation

- 1%

- Storage Temperature

- -40C to 85C

- Weight

- 3.7 kg

- Mounting Type

- DIN Rail / Panel Mount

- Enclosure Color

- Gray / Black

- Positioning Accuracy

- ±0.01 mm

- Digital Inputs

- 8

- Brake Control

- Integrated

- Emergency Stop Input

- Yes

- Communication Ports

- Ethernet/IP, RS232, RS485

- Analog Inputs

- 2

- Control Method

- Vector Control / V/f Control

- Firmware Upgrade

- Field Upgradable

- Encoder Feedback

- Supported

- Relative Humidity

- 5% to 95% Non-condensing

- Protection Class

- IP20

- Digital Outputs

- 4

- Display Type

- LED / LCD Status Indication

About ALLEN BRADLEY INTEGRATED AXIS MODULE

Industry-Defining Versatility and Features

Suitable for industrial motion control, automation, and robotics, the Allen Bradley Integrated Axis Module excels in demanding applications. Its compact design accommodates multiple mounting types (DIN rail or panel), and it features advanced diagnostics through LED/LCD displays. Integrated Safe Torque-Off, multiple digital and analog I/Os, and encoder feedback support enhance its usability. Choose this robust module for applications requiring precise positioning, reliable communication, and secure motor control, all backed by Allen Bradleys reputation for durability and performance.

Seamless Logistics and Quick Exchange Policies

Experience efficient ordering and arrival with our quick dispatch system for the Allen Bradley Integrated Axis Module. FOB port options are available to suit your needs, ensuring timely delivery to your facility. We prioritize the main domestic market with excellent stock levels, making exchanges and sample requests simple and hassle-free. Benefit from flexible sample policies and responsive support, ensuring you receive the right product when and where you need it, every time.

FAQs of ALLEN BRADLEY INTEGRATED AXIS MODULE:

Q: How does the integrated axis module support various industrial automation applications?

A: The Allen Bradley Integrated Axis Module is designed for high-precision motion control, making it suitable for automation, robotics, and other industrial processes requiring reliable, safe, and versatile motor management.Q: What features ensure operational safety and efficiency in this module?

A: The module incorporates integrated Safe Torque-Off (STO), advanced diagnostics via LED/LCD, overvoltage and undervoltage protection, and robust communication interfaces to ensure both safety and high operational efficiency.Q: When can I expect my order to arrive, and is quick dispatch available?

A: Quick dispatch is a key part of our service. Orders are processed rapidly, and, depending on your location, you can typically expect prompt arrival thanks to our efficient shipping and FOB port options.Q: Where is the Allen Bradley Integrated Axis Module suitable for installation?

A: With its DIN rail and panel mounting capabilities, the module is suitable for installation in various industrial control panels, machinery, and automated robotics setups across multiple environments.Q: What is the process for firmware upgrades and product exchanges?

A: Field-upgradable firmware ensures your module stays current with the latest features. If an exchange is necessary, our streamlined domestic market process and flexible sample policy make it quick and convenient.Q: How can I benefit from the diagnostics and status indication features?

A: Diagnostics LEDs and the clear status indication displays enable proactive monitoring and troubleshooting, reducing downtime and enhancing productivity in your industrial systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY POWER SUPPLY

Power Supply : Switch Mode Power Supply (SMPS)

Storage Temperature : 40C to 85C

Output Type : Single

Product Type : Industrial Power Supply

Application : Industrial Automation, Control Panels, Machinery

Material : Metal Housing

ALLEN BRADLEY SERVO DRIVE

Power Supply : AC Mains

Storage Temperature : 20C to +65C

Output Type : Other, Analog / Digital

Product Type : Servo Drive

Application : Industrial Automation, CNC Machinery, Robotics

Material : Industrial Grade Plastic and Metal

ALLEN-BRADLEY 1JAL3SP404450

Power Supply : AC Input

Storage Temperature : 20C to 85C

Output Type : AC

Product Type : Soft Starter

Application : Motor Control

Material : Plastic and Metal

1746-NO4I ALLEN BRADLEY 1746 SLC 500

Power Supply : External

Storage Temperature : 40C to 85C

Output Type : Other, Analog

Product Type : 1746NO4I ALLEN BRADLEY 1746 SLC 500

Application : Industrial Automation

Material : Highgrade Plastic and Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry