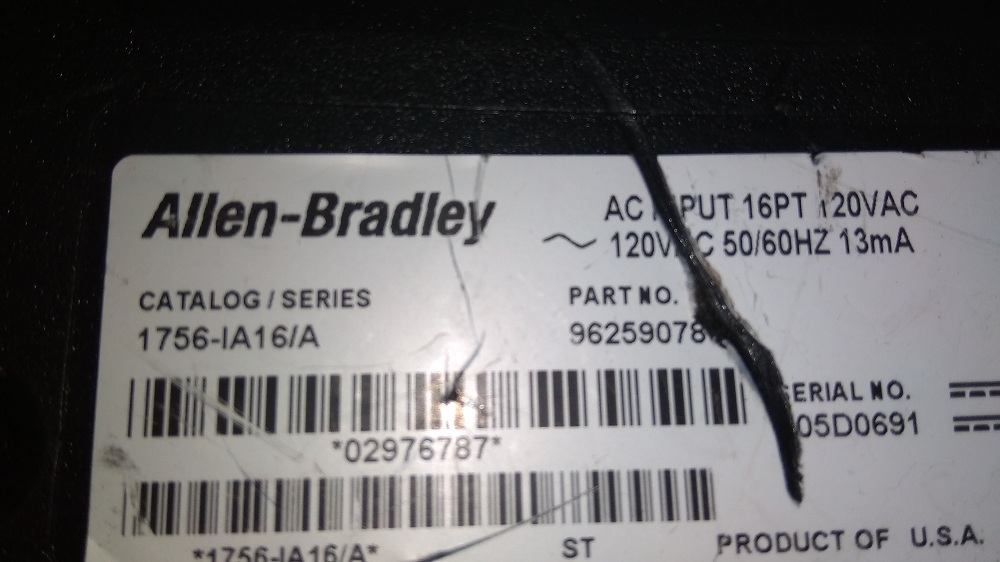

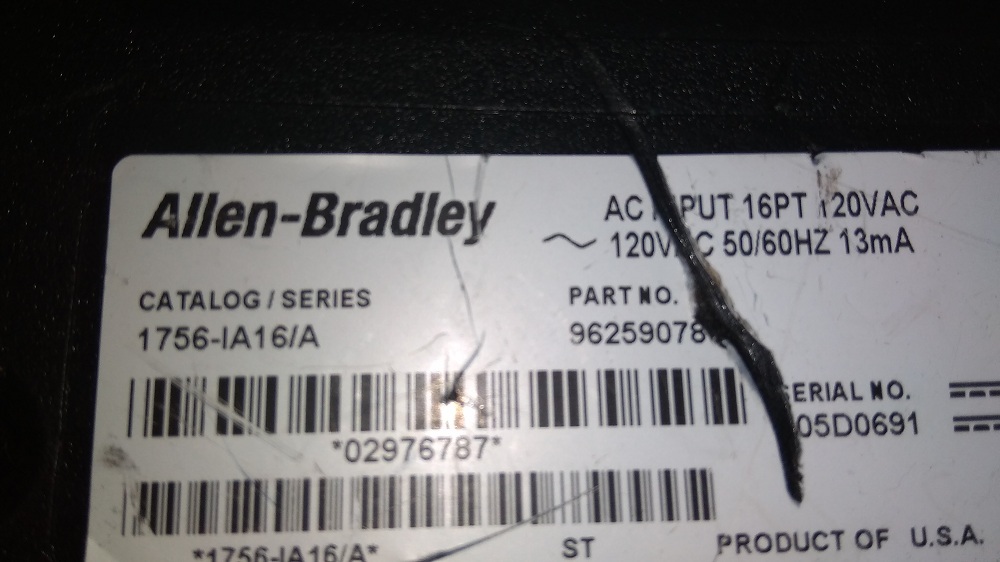

ALLEN BRADLEY INPUT OUTPUT MODULE

ALLEN BRADLEY INPUT OUTPUT MODULE Specification

- Way

- Multi-channel

- Features

- Hot-swappable, Diagnostics, Easy installation

- Rated Operation Voltage

- 24V DC

- Current Rating

- 2A

- Operating Voltage

- 24V DC

- Connectivity Type

- Screw Terminal, Backplane Bus

- Panel Type

- Modular

- Thickness

- Standard (as per model)

- Components

- LED indicators, terminal connectors

- Protection Class

- Class II

- Cooling System

- Natural Air Cooling

- Rated Current

- 2A

- Base Material

- Polycarbonate

- Protection Level

- IP20

- Rated Insulation Voltage

- 500V AC

- Control System

- Compatible with Allen Bradley PLC

- Cover Material

- Polycarbonate

- Product Type

- Input Output Module

- Material

- Plastic, Metal

- Surface Finish

- Matte

- Standard

- IEC 61131

- Surface Color

- Grey

- Rated Voltage

- 24V DC

- Frequency (MHz)

- DC Operating; Not Applicable

- Maximum Output Current

- 2A per channel

- Dimension (L*W*H)

- Approximated 120 x 50 x 75 mm

- Application

- Industrial Automation, PLC Systems

- IP Rating

- IP20

- Display Type

- LED Status Indicators

About ALLEN BRADLEY INPUT OUTPUT MODULE

Diverse Applications and Competitive Edge

The ALLEN BRADLEY INPUT OUTPUT MODULE excels in varied applications such as conveyor systems, process controls, packaging machinery, and energy management. Its pristine reliability and hot-swappable capability ensure minimal downtime in competitive high-speed automation arenas. As a premier solution, it offers diagnostics, multi-channel configurations, and modularitya highlighted advantage for businesses seeking scalable and efficient I/O integration. Suitability for complex PLC systems makes it a top choice in automotive, food processing, and manufacturing facilities globally.

Certifications, Sample Offerings, and Handling

Securing trust, the ALLEN BRADLEY INPUT OUTPUT MODULE is RoHS compliant and aligns with the acclaimed IEC 61131 standard, ensuring global operability. Interested buyers can request samples to verify compatibility. Delivered with secure packaging and reliable carriers, the module is offered at the lowest price through our FOB port. Each order is processed with meticulous attention, ensuring prompt, safe shipping to any locationmaking it a favored supplier and trader option for critical automation projects.

FAQs of ALLEN BRADLEY INPUT OUTPUT MODULE:

Q: How does the ALLEN BRADLEY INPUT OUTPUT MODULE enhance industrial automation processes?

A: By offering rapid response times under 1ms, multi-channel configurations, and superior diagnostics, this module streamlines data acquisition and facilitates reliable real-time control in diverse automation environments.Q: What are the main application areas for this I/O module?

A: It is ideally suited for industrial automation, including PLC systems, conveyor lines, process control, energy management, packaging machines, and large-scale manufacturing sectors such as automotive and food processing.Q: When is it beneficial to use the hot-swappable feature of this module?

A: The hot-swappable design becomes invaluable during maintenance or expansion, allowing you to replace or add modules without shutting down operations, resulting in minimal downtime and improved productivity.Q: Where can the ALLEN BRADLEY I/O MODULE be installed?

A: Designed for DIN rail mounting, it can be installed inside standard electrical enclosures or control panels within industrial environments that meet the operating conditions described in the datasheet.Q: What competitive advantages does this module offer over traditional I/O systems?

A: It provides diagnostics, modularity, industry-standard compliance, rapid installation, and rigorous protection (IP20, Class II), delivering a powerful advantage in flexibility and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY MODULE CPU POWER SUPPLY Category

ALLEN BRADLEY INPUT OUTPUT MODULE

Protection Level : Other, IP20

Rated Insulation Voltage : 250V AC

Control System : PLC (Programmable Logic Controller)

Standard : IEC Certified

Cover Material : Other, Polycarbonate

Application : Industrial Automation, Process Control Systems

ALLEN BRADLEY INPUT OUTPUT MODULE

Protection Level : Other, IP20

Rated Insulation Voltage : 500V AC

Control System : PLC

Standard : IEC/EN 611312

Cover Material : Other, ABS Plastic

Application : Automation System

ALLEN BRADLEY INPUT OUTPUT MODULE

Protection Level : Other, IP20

Rated Insulation Voltage : 500V AC

Control System : PLC Integratable

Standard : IEC 611312

Cover Material : Other, Polycarbonate

Application : Industrial Automation, PLC Systems

ALLEN BRADLEY ANALOG INPUT MODULE

Protection Level : Other, IP20

Rated Insulation Voltage : 250V AC/DC

Control System : PLC Compatible

Standard : IEC

Cover Material : Other, Polycarbonate

Application : Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry