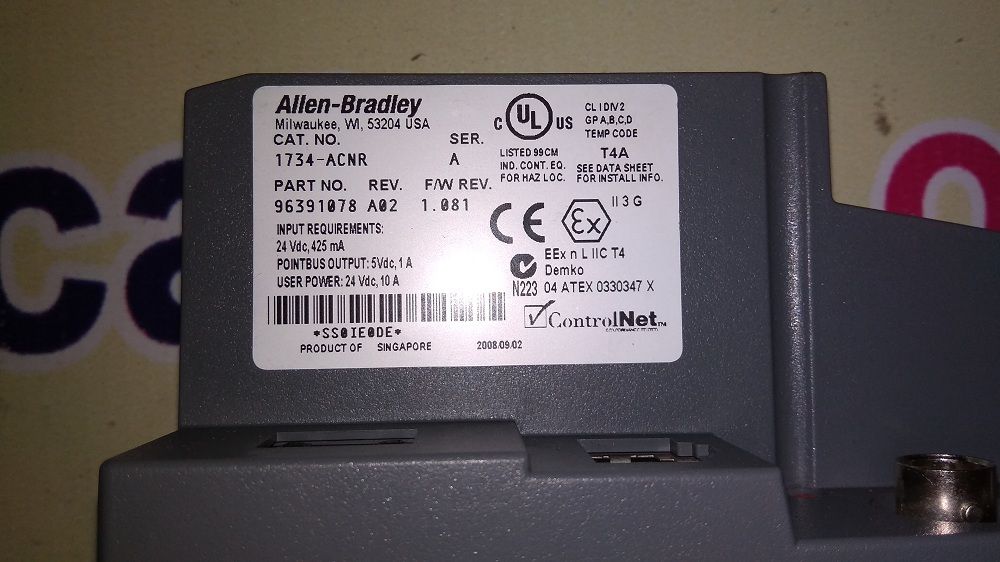

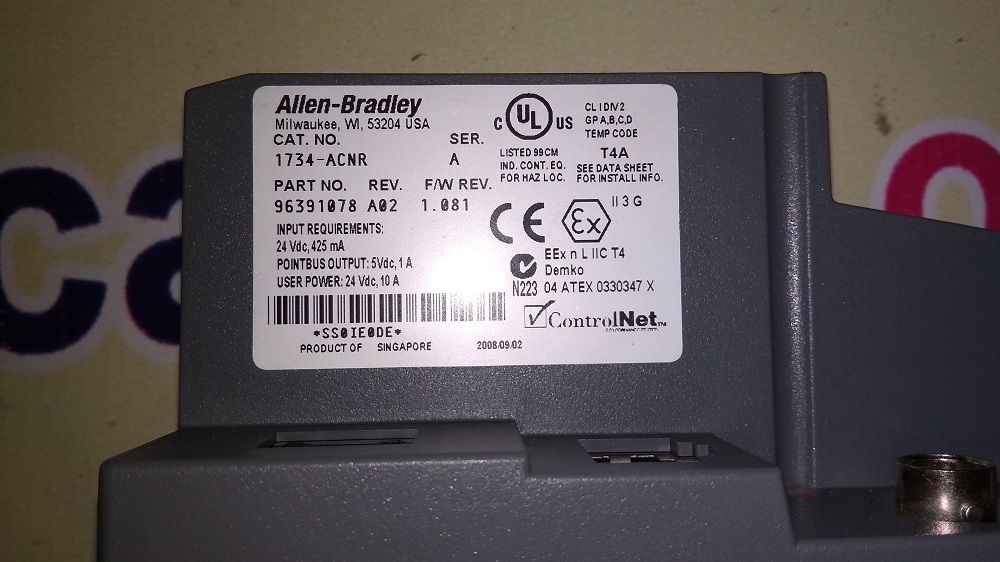

ALLEN BRADLEY CPU

ALLEN BRADLEY CPU Specification

- Thickness

- 55 mm

- Base Material

- Die-Cast Aluminium

- Way

- Single

- Features

- High Speed Processing, Real-Time Monitoring, Modular Design

- Operating Voltage

- 24V DC

- Protection Level

- IP20

- Rated Operation Voltage

- 24V DC

- Protection Class

- Class II

- Cabinet Material

- Metal

- Rated Current

- 2A Per Channel

- Cooling System

- Passive Cooling

- Panel Type

- Mounting Panel

- Current Rating

- 2A

- Control System

- Microprocessor-Based

- Rated Insulation Voltage

- 500V AC

- Connectivity Type

- Ethernet, Serial Port (RS232, RS485)

- Components

- Main Processor, Memory Module, Communication Ports

- Cover Material

- Polycarbonate

- Product Type

- Programmable Logic Controller CPU Module

- Material

- Industrial Grade Plastic, Metal Base

- Surface Finish

- Matte

- Standard

- IEC 61131, UL, CE

- Surface Color

- Gray

- Rated Voltage

- 24V DC

- Frequency (MHz)

- 50-60 Hz

- Maximum Output Current

- 2A

- Dimension (L*W*H)

- 118 x 35 x 87 mm

- Application

- Industrial Automation, Control Panel Automation

- IP Rating

- IP20

- Display Type

- LED Indicator

About ALLEN BRADLEY CPU

Application Surface and Competitive Advantages

This ALLEN BRADLEY CPU is optimized for control panel automation in industrial environments. Its sturdy die-cast aluminium base and polycarbonate cover make it suitable for harsh conditions, providing reliable IP20 protection. The device stands out with high-speed processing, real-time monitoring, and efficient passive cooling. Its modular design offers scalability and adaptability, giving users a competitive edge when managing complex automation requirements for factories, process plants, and manufacturing setups.

FOB Port and Export Market Details

ALLEN BRADLEY CPUs are shipped promptly from established FOB ports, ensuring quick dispatch to various destinations. The main export markets include Southeast Asia, Europe, and North America, where demand for industrial automation solutions is robust. Samples are available for domestic markets, allowing traders and buyers to assess product quality before large-scale purchases. Efficient shipment processes guarantee timely delivery, supporting both local and globe-wide automation needs.

FAQs of ALLEN BRADLEY CPU:

Q: How do I install the ALLEN BRADLEY CPU in my industrial control panel?

A: Installation is straightforward on either DIN rail or a mounting panel. Ensure you follow IEC 61131, UL, and CE standards, connect power and communication cables, and secure the unit with appropriate screws for reliable operation.Q: What protocols are supported for communication and integration?

A: The CPU supports Ethernet/IP, Modbus RTU, DH+ (Data Highway Plus), RS232, and RS485, making it versatile for integration into diverse control systems and industrial networks.Q: When is it necessary to upgrade the firmware, and how is this done?

A: Firmware upgrades are recommended periodically or when new features are released. Upgrades can be accomplished easily via USB or Ethernet, ensuring your system benefits from the latest enhancements and security updates.Q: Where is the optimal environment for using this CPU?

A: The device is best suited for industrial automation settings with operating temperatures between 0C and 60C and storage conditions of -40C to 85C. Its IP20 rating makes it ideal for protected indoor environments.Q: What specific benefits does the modular design offer in industrial usage?

A: The modular design allows you to expand the CPUs input/output capabilities efficiently, adapting to evolving automation needs and streamlining maintenance by making upgrades and repairs hassle-free.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY MODULE CPU POWER SUPPLY Category

ALLEN BRADLEY INPUT OUTPUT MODULE

Connectivity Type : Screw Terminal

Components : Microcontroller, Relay, Terminal Block

Frequency (MHz) : 50/60 Hz

Cover Material : Other, Polycarbonate

Cooling System : Passive

Panel Type : DIN Rail Mount

ALLEN BRADLEY INPUT OUTPUT MODULE 1746-NIO4V

Connectivity Type : Backplane

Components : Analog I/O Channels, Terminal Block

Frequency (MHz) : 50/60 Hz

Cover Material : Other, Plastic

Cooling System : Natural air cooling

Panel Type : DIN Rail Mount

ALLEN BRADLEY 1766 L32BWAA MICROLOGIX 1400 PROGRAMMABLE CONTROLLER

Connectivity Type : Ethernet/IP, RS232, RS485

Components : Integrated communication ports, Ethernet, RS232, RS485

Frequency (MHz) : 50/60 Hz

Cover Material : Other, Plastic outer shell

Cooling System : Natural convection air cooling

Panel Type : DIN rail mountable

ALLEN BRADLEY INPUT OUTPUT MODULE

Connectivity Type : Screw Terminal

Components : Solid State Electronics

Frequency (MHz) : 50/60 Hz

Cover Material : Other, Polycarbonate

Cooling System : Natural Air Cooling

Panel Type : DIN Rail Mounted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry