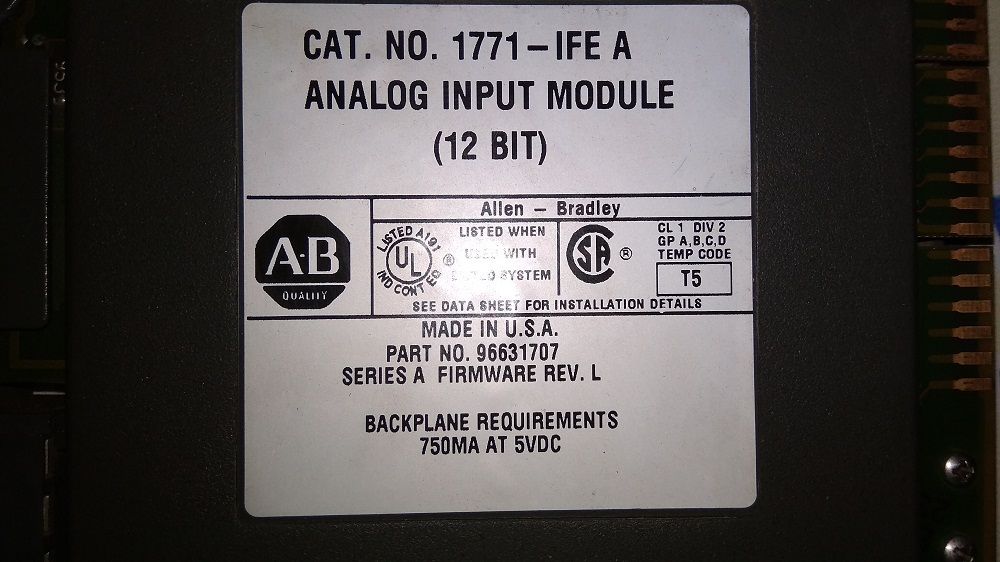

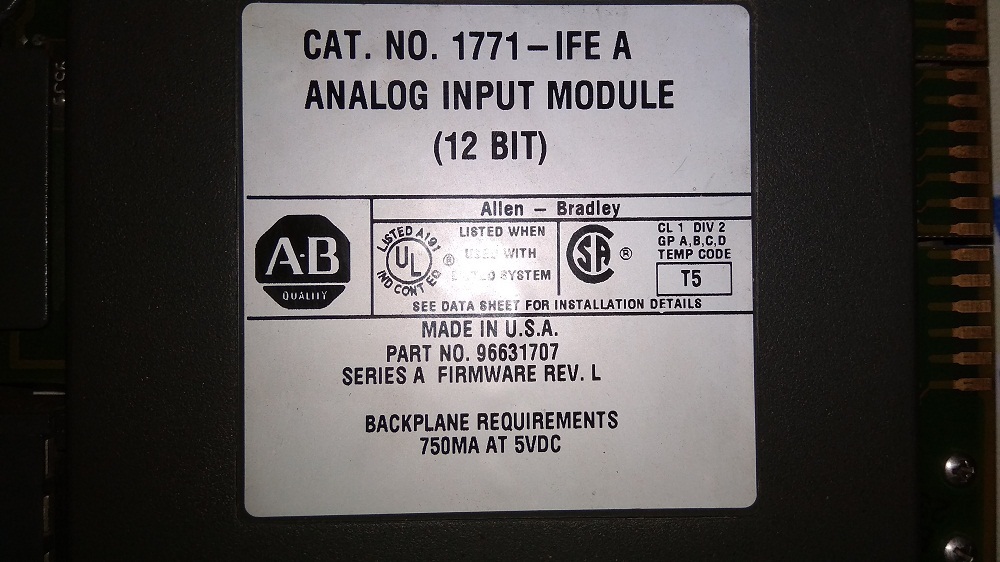

ALLEN BRADLEY ANALOG INPUT MODULE

ALLEN BRADLEY ANALOG INPUT MODULE Specification

- Working Temperature

- 0C to +60C

- Features

- 16-bit resolution, LED indication, Hot-swap, Channel diagnostic

- Cooling Method

- Natural Convection

- Power Supply

- Backplane powered (via PLC rack); 24V DC input

- Connector Type

- Removable terminal block or cage clamp (model dependent)

- Output Type

- Analog (Input Only)

- Application

- Industrial Automation, Process Control, PLC Systems

- Operating Temperature

- 0C to +60C

- Current Range

- 4-20 mA, 0-20 mA; 0-10V, 10V (model dependent)

- Noise Level

- < 10 Vrms (input noise)

- Product Type

- Analog Input Module

- Input Voltage

- 24V DC (typical), Range: 10-30V DC

- Voltage Protection

- Overvoltage and reverse polarity protection

- Material

- Polycarbonate, Metal

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 250g

- Number Of Channels

- 4, 8, or 16 (model specific)

- Isolation

- Channel-to-channel and channel-to-backplane isolation

- Resolution

- 16-bit

- Input Signal Type

- Voltage or Current (Configurable)

- Protection Level

- IP20

- Mounting Type

- DIN Rail

- Series

- PLC 5 / SLC 500 / CompactLogix / ControlLogix (model dependent)

- Input Impedance

- Voltage: >1 M, Current: 250

- Status Indication

- LED channel status indicators

- Response Time

- Up to 1 ms per channel

About ALLEN BRADLEY ANALOG INPUT MODULE

Distinguished Features & Versatile Applications

ALLEN BRADLEY ANALOG INPUT MODULE ensures remarkable precision with 16-bit resolution and instantaneous channel diagnostics. Its LED status indicators, hot-swap feature, and natural convection cooling method elevate operational convenience and safety. Widely adopted in industrial automation, process control, and PLC systems, it stands out for superior noise immunity and robust construction. Competitive advantages include seamless mounting, advanced isolation, configurable signal types, and user-friendly maintenance, making it an ideal choice for demanding industrial environments.

Sample Policy, Supply Capacity & Export Markets

Samples of the ALLEN BRADLEY ANALOG INPUT MODULE can be handed over upon request, with estimated delivery periods communicated prior to drop-off. Our supply ability meets large-scale industrial requirements with reliable stock and rapid order processing. Main export markets include North America, Europe, the Middle East, and Asia, ensuring prompt international delivery and support. Commitment to excellence guarantees competitive pricing and responsive after-sales service for all global clients.

FAQs of ALLEN BRADLEY ANALOG INPUT MODULE:

Q: How do I configure the input signal type on the ALLEN BRADLEY ANALOG INPUT MODULE?

A: Input signal type selection, between voltage or current, is model-specific and can be configured using module setup instructions included with the product documentation.Q: What benefits does channel-to-channel and channel-to-backplane isolation provide?

A: These isolation methods enhance signal integrity, minimize interference between channels and the PLC system, ensuring reliable performance even in complex industrial applications.Q: When should I utilize the hot-swap feature on this module?

A: The hot-swap feature allows you to replace or add modules while the system is powered, reducing downtime and maintaining productivity during upgrades or maintenance.Q: Where are LED channel status indicators located and what information do they convey?

A: LED indicators are positioned on the modules front panel. They provide instant status updates for each channel, aiding rapid diagnostics and system monitoring.Q: What process is recommended if input voltage exceeds the modules typical range?

A: If input voltage surpasses the typical 24V DC or the 10-30V DC range, overvoltage protection will activate. Its advised to monitor and correct power supply sources to prevent damages.Q: How does natural convection cooling benefit module operation?

A: Natural convection cooling guarantees efficient heat dissipation without the need for external fans, contributing to silent, reliable module operation in diverse temperature environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY USED PLC SERVO DRIVE

Operating Temperature : 0C to +55C

Voltage Protection : Overvoltage, Undervoltage

Working Temperature : 0C to +55C

Features : Position, Velocity, and Torque Control; Diagnostic LEDs; AutoTuning; Communication Ready

Product Type : Used PLC Servo Drive

Input Voltage : 200240V AC, 400480V AC (model specific)

ALLEN BRADLEY KINETIX 6000 DRIVE 2094-BC07-M05-M

Operating Temperature : 0C to 50C

Voltage Protection : Overvoltage Protection

Working Temperature : 0C to 50C

Features : Compact design High performance

Product Type : Servo Drive

Input Voltage : 230V AC

ALLEN BRADLEY SD3000 PLUS DRIVE CONTROL SD3000 PLUS 96421674

Operating Temperature : 10C to 50C

Voltage Protection : Overvoltage and undervoltage protection

Working Temperature : 10C to 50C

Features : Digital display, programmable inputs/outputs, fault diagnostics

Product Type : SD3000 PLUS Drive Control

Input Voltage : 380480 VAC

ALLEN BRADLEY MICROLOGIX 1200 PLC 1762-L24BWAR

Operating Temperature : 0C to 55C

Voltage Protection : Surge protection included

Working Temperature : 0C to 55C

Features : Programmable logic controller with enhanced I/O and communication capabilities

Product Type : Programmable Logic Controller (PLC)

Input Voltage : 24V DC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry