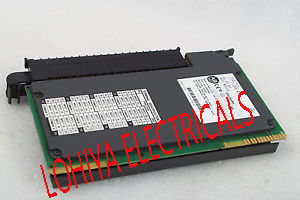

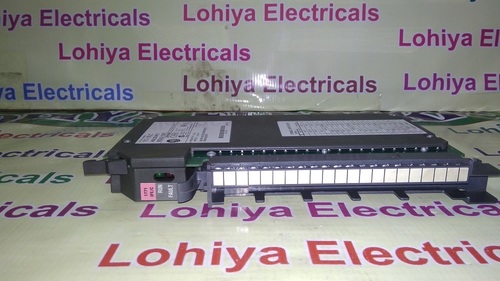

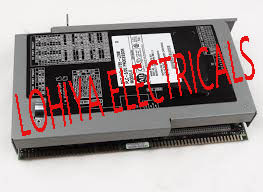

ALLEN BRADLEY 1785 CPU

ALLEN BRADLEY 1785 CPU Specification

- Connector Type

- Edge card connector for PLC chassis slot

- Cooling Method

- Passive cooling, air convection

- Operating Temperature

- 0C to 60C

- Working Temperature

- 0C to 60C

- Power Supply

- Powered via PLC-5 chassis backplane

- Features

- Hot swapping capability, Onboard diagnostics, Expandable memory options, High-speed task execution

- Noise Level

- Low, suitable for control rooms

- Application

- PLC-5 Programmable Logic Controller for Industrial Automation

- Product Type

- Programmable Controller CPU

- Input Voltage

- 5V DC (Backplane) - Power supplied by PLC chassis

- Voltage Protection

- Overvoltage and reverse voltage protection via chassis power supply

- Efficiency

- High processing efficiency for industrial automation

- Material

- Industrial grade plastic and metal components

- Line Regulation

- Regulated by chassis power supply

- Storage Temperature

- -40C to 85C

- Weight

- Approx. 2 kg (varies by model)

- Mounting Type

- Rack-mounted, PLC-5 chassis slot

- Dimensions

- Approx. 340 x 138 x 132 mm (varies by model)

- Firmware Upgrade

- Field upgradeable firmware

- Instruction Set

- Relay ladder logic, block transfer, sequencer, math, PID control

- Memory Capacity

- Varies by CPU model; up to 64K words

- Redundancy Support

- Supported in select models

- Processor Options

- Multiple models (e.g., 1785-L20B, 1785-L40E, 1785-L60L, 1785-L80E)

- Communication Ports

- DH+, Ethernet, Remote I/O, RS-232C (model dependent)

- Compatible Chassis

- Allen-Bradley PLC-5 Series Chassis

About ALLEN BRADLEY 1785 CPU

ALLEN BRADLEY 1785 CPU 1785-L20B DVersatile Processor Options

Choose from a range of ALLEN BRADLEY 1785 CPU models to best suit your industrial applications needs. Options like 1785-L20B, 1785-L40E, 1785-L60L, and 1785-L80E offer scalable memory and processing power. This flexibility supports everything from simple control tasks to complex automation processes. Adapt your system with ease, thanks to field-upgradeable firmware and expandability.

Industrial-Grade Reliability

Built with robust plastic and metal components, the 1785 CPU thrives in harsh environments. It features advanced voltage protection and operates within a wide temperature range (0C to 60C). The rack-mounted, passive-cooled design ensures efficient performance while maintaining low noise levels, making it suitable for control rooms and industrial sites alike.

Efficient Communication and Diagnostics

Multiple communication ports, including DH+, Ethernet, Remote I/O, and RS-232C, make integration seamless with various network topologies. Onboard diagnostics and hot swapping capabilities increase uptime and simplify maintenance. Benefit from high-speed task execution and reliable data transfer for demanding automation operations.

FAQs of ALLEN BRADLEY 1785 CPU:

Q: How do I select the appropriate ALLEN BRADLEY 1785 CPU model for my application?

A: Selection depends on your desired processing power, memory requirements, and available communication ports. Models such as 1785-L20B, 1785-L40E, 1785-L60L, and 1785-L80E offer varying memory capacity and port options. Assess your automation complexity and required redundancy to identify the best fit.Q: What is the process for mounting the 1785 CPU in my PLC-5 chassis?

A: The 1785 CPU is designed to be rack-mounted using an edge card connector. Simply insert the CPU into a compatible slot on your Allen-Bradley PLC-5 Series Chassis, ensuring correct alignment and secure attachment for reliable operation.Q: Where can the ALLEN BRADLEY 1785 CPU be installed for optimal performance?

A: It is intended for use in regulated industrial environments, such as factory control rooms. The CPU functions efficiently in ambient temperatures from 0C to 60C and should be installed in a well-ventilated enclosure to benefit from its passive cooling design.Q: When is firmware upgrading necessary, and how is it performed on the 1785 CPU?

A: Firmware upgrades are recommended when new features, enhancements, or security fixes are released by the manufacturer. Upgrading is performed in the field using appropriate tools and updates provided by Allen-Bradley, ensuring minimal disruption to your control process.Q: What benefits does redundancy support provide in select 1785 CPU models?

A: Redundancy support guarantees continuous operation in mission-critical environments by allowing failover functionality. In case of a primary processor fault, a backup can immediately assume control, minimizing downtime and enhancing process safety.Q: How does the onboard diagnostics feature improve maintenance and troubleshooting?

A: Onboard diagnostics help detect faults, monitor system health, and simplify troubleshooting. This reduces maintenance time and enables quicker resolution of issues, thereby improving system reliability and reducing operational costs.Q: What usage scenarios are ideal for the ALLEN BRADLEY 1785 CPU?

A: The 1785 CPU excels in industrial automation scenarios like process control, manufacturing, assembly lines, and utilities. Its high processing efficiency and robust communication capabilities make it suitable for complex, automated control systems in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY Used PLC SERVO DRIVE Category

ALLEN BRADLEY POWER SUPPLY

Storage Temperature : 40C to +85C

Material : Metal Enclosure

Features : Compact Design Reliable Performance

Output Type : DC

Operating Temperature : 25C to +70C

Application : Industrial Automation

ALLEN BRADLEY MODULE

Storage Temperature : 40C to 85C

Material : Polycarbonate, Metal

Features : Hotswappable, Compact Design, DIN Rail Mountable, LED Status Indication

Output Type : Other, Digital

Operating Temperature : 20C to 60C

Application : Industrial Automation, Process Control

ALLEN BRADLEY INPUT OUTPUT MODULE 1771-OBD

Storage Temperature : 40C to +85C

Material : Industrialgrade PCB and enclosure

Features : 16point Digital Output, Overcurrent Protection, Status Indicators

Output Type : Other, Digital (DC Output)

Operating Temperature : 0C to +60C

Application : Industrial Automation, PLC Systems

ALLEN BRADLEY INPUT OUTPUT MODULE 1771-IFE/C

Storage Temperature : 40C to 85C

Material : Plastic, Metal

Features : 16 Differential Inputs, Analog Input

Output Type : Other, Analog Input

Operating Temperature : 0C to 60C

Application : Industrial Automation, PLC Systems

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry