ACOPOS SERVO DRIVE

ACOPOS SERVO DRIVE Specification

- Power Supply

- AC Mains, 3-phase, 50/60Hz

- Noise Level

- <60 dB(A)

- Current Range

- 37.5 A

- Connector Type

- Screw terminals and plug-in connectors

- Rated Current

- 5 A

- Output Type

- Digital and analog outputs

- Cooling Method

- Integrated fan cooling

- Phase

- Three Phase

- Working Temperature

- 0C to +55C

- Operating Temperature

- 0C to +55C

- Features

- Compact design, real-time Ethernet, integrated safety functions, modular scalability

- Application

- Automated machinery, robotics, packaging, CNC, material handling

- Output Current

- Up to 7.5 A (depending on model)

- Rated Power

- 1.5 kW (model specific)

- Power Factor

- >= 0.96

- Product Type

- Servo Drive

- Output Power

- 1 to 2.5 kW (model dependent)

- Output Frequency

- 0600 Hz

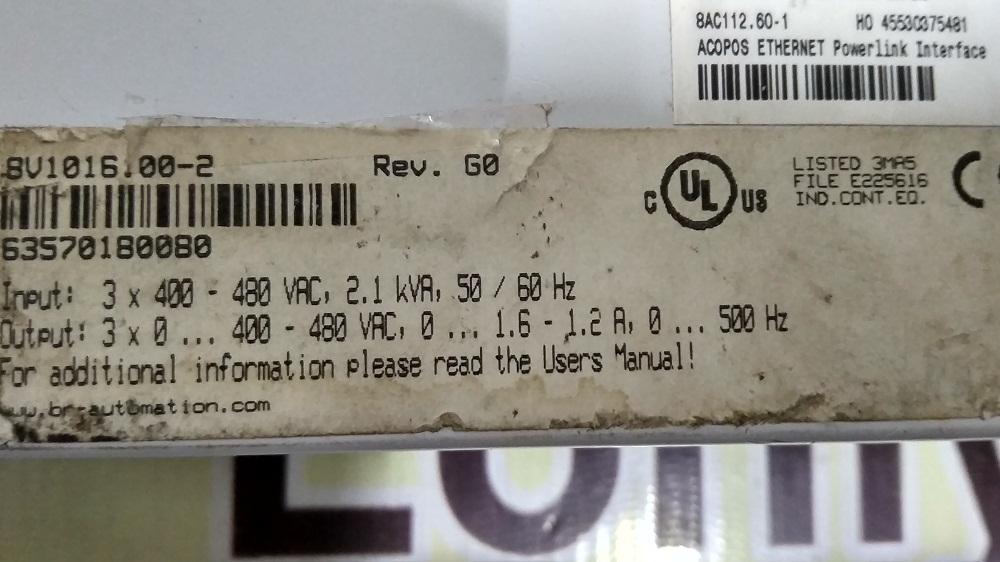

- Input Voltage

- 3 x 400480 V AC (+10% / -15%)

- Voltage Protection

- Overvoltage and undervoltage protection

- Efficiency

- >= 95%

- Material

- Aluminum housing with high-grade electronics

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- 1.53.5 kg (varies by model)

About ACOPOS SERVO DRIVE

Material Excellence & Feature Highlights

The ACOPOS SERVO DRIVE is crafted from robust aluminum housing paired with high-grade electronics, ensuring resilience in demanding environments. With features like modular scalability, real-time Ethernet, integrated safety options, and a compact footprint, it delivers both versatility and reliability. Primarily used by automation professionals in sectors such as robotics, CNC machinery, and packaging, the drives dynamic braking, advanced control modes, and low noise level substantiate its appeal for modern industrial applications.

Sample Policy & Premium Shipment Details

Delivered with attention to detail, our ACOPOS SERVO DRIVE samples are available subject to moderate expenditure, reflecting the products premium positioning. Samples are dispatched from a major FOB port, ensuring secure and prompt arrival. We strive to provide potential partners with hands-on evaluation opportunities, demonstrating the drives remarkable value and performance in real-world scenarios. Engage with us today to explore how our product supports your automation portfolio through a seamless sample acquisition process.

FAQs of ACOPOS SERVO DRIVE:

Q: How do I install the ACOPOS SERVO DRIVE?

A: The ACOPOS SERVO DRIVE can be mounted either on a DIN rail or panel, using screw terminals or plug-in connectors. Follow the installation guidelines in the user manual for safe and secure setup.Q: What communication interfaces does this servo drive support?

A: This servo drive supports Ethernet POWERLINK, CAN, X2X, and RS232 interfaces, ensuring seamless integration with a variety of automation systems.Q: How does the integrated safety function benefit my systems?

A: The inclusion of Safe Torque Off (STO) and Safe Stop functions provides added protection for personnel and equipment, minimizing risk and enhancing workplace safety.Q: When should I use dynamic braking in my application?

A: Integrated dynamic braking is recommended for applications requiring rapid deceleration or precise position control, such as robotics or CNC equipment.Q: What is the process for obtaining a sample ACOPOS SERVO DRIVE?

A: Contact our sales team to request a sample. Samples are available for interested partners, with shipping handled via a secure FOB port and costs determined according to current market policies.Q: Where can the ACOPOS SERVO DRIVE be applied?

A: This unit is versatile, suitable for automated machinery, robotics, packaging, material handling, and CNC operations, offering reliable performance across diverse industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B & R Used PLC HMI SERVO DRIVE Category

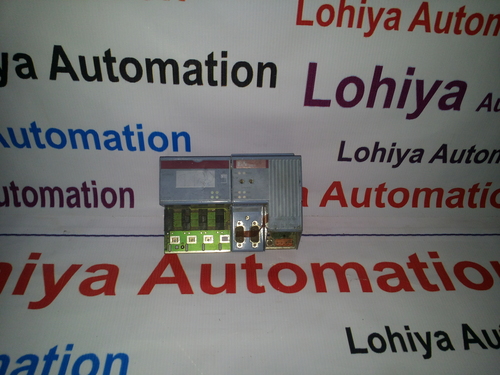

ACOPOS SERVO DRIVE

Product Type : ACOPOS Servo Drive

Voltage Protection : Overvoltage/Undervoltage Protection

Connector Type : Screw Terminal/Plugin Connectors

Storage Temperature : 40C to +70C

Weight : Approx. 2.4 kg

Noise Level : 50 dB(A)

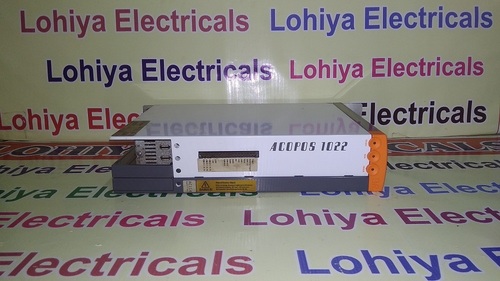

ACOPOS 1016 SERVO DRIVE

Product Type : Servo Drive

Voltage Protection : Overvoltage, Undervoltage, Shortcircuit protection integrated

Connector Type : Pluggable spring terminal blocks

Storage Temperature : 25C to +70C

Weight : Approx. 1.9 kg

Noise Level : <55 dB

B&R CP474

Product Type : Power Supply Unit

Voltage Protection : Overvoltage, Overload, ShortCircuit Protection

Connector Type : Screw Terminal

Storage Temperature : 40C to +85C

Weight : Approx. 0.65 kg

Noise Level : < 50 mVpp

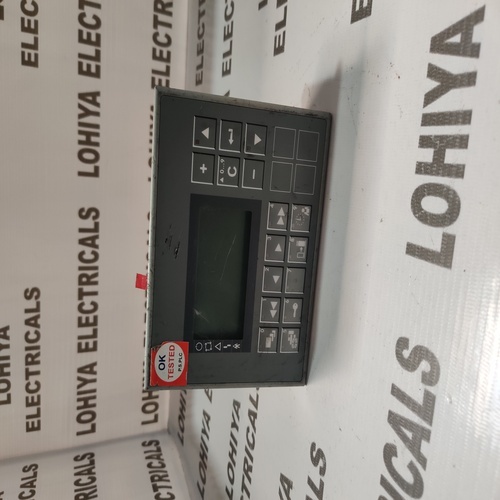

B&R 4PP035.0300-K18 HMI

Product Type : HMI (Human Machine Interface)

Voltage Protection : Reverse polarity protection and overvoltage protection

Connector Type : Screw terminal for power, RS232/RS422/RS485, USB, Ethernet

Storage Temperature : 20C to +70C

Weight : Approx. 450 g

Noise Level : Silent operation (fanless design)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry