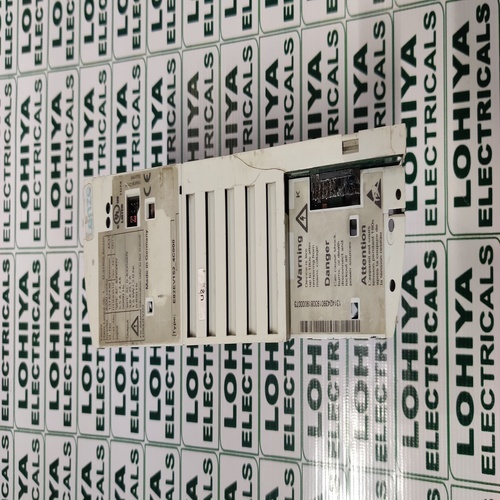

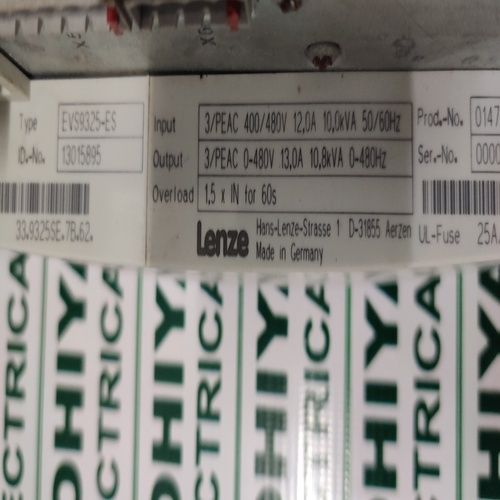

LENZE EVS9325 ES DRIVE

LENZE EVS9325 ES DRIVE Specification

- Working Temperature

- 0C to +45C

- Output Current

- 12 A

- Operating Temperature

- 0C to +45C

- Output Type

- Three Phase

- Power Supply

- AC (400-480V), 50/60 Hz

- Rated Current

- 12 A

- Connector Type

- Screw Terminal

- Noise Level

- <70 dB(A)

- Features

- Integrated Brake Chopper, Built-in EMC Filter, Multiple Communication Options, User-Friendly Keypad

- Application

- Industrial Automation, Conveyor Systems, Pumps, Fans

- Rated Power

- 5.5 kW

- Cooling Method

- Fan Cooling

- Power Factor

- >= 0.95

- Current Range

- 0-12 A

- Phase

- Three Phase

- Product Type

- AC Drive / Frequency Inverter

- Output Power

- 5.5 kW

- Output Frequency

- 0 - 599 Hz

- Input Voltage

- 400-480 V AC

- Voltage Protection

- Integrated Overvoltage / Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- Metal with Protective Coating

- Line Regulation

- 1%

- Storage Temperature

- -25C to +55C

- Weight

- approx. 7 kg

About LENZE EVS9325 ES DRIVE

Applications and Advantages of LENZE EVS9325 ES DRIVE

Designed for industrial automation, conveyor systems, pumps, and fans, the LENZE EVS9325 ES DRIVE offers crowning versatility and magnificent reliability. Its use type suits continuous, demanding operations, ensuring stellar performance in various environments. Reserved for users prioritizing stability, the drive guarantees advanced overload protection and superb efficiency, making it a competitive choice in its category.

Packaging, Shipping, and Market Coverage

Each LENZE EVS9325 ES DRIVE is securely dispatched with express shipping options for both export and domestic mar clients. Precision packaging safeguards the product during transit to global markets and primary domestic mar regions, ensuring prompt delivery and pristine condition. Supplier and trader partners benefit from seamless logistics designed for timely arrival in all main export destinations and leading local market sectors.

FAQs of LENZE EVS9325 ES DRIVE:

Q: How does the LENZE EVS9325 ES DRIVE manage overvoltage and undervoltage situations?

A: The LENZE EVS9325 ES DRIVE features integrated protection systems that actively monitor voltage levels and automatically safeguard the drive against both overvoltage and undervoltage, ensuring stable operation and extending product lifespan.Q: What are the primary uses for this drive in industrial settings?

A: This drive excels in industrial automation tasks such as controlling conveyor systems, pumps, and fans, providing reliable, continuous performance under demanding conditions.Q: Where can the LENZE EVS9325 ES DRIVE be mounted for optimal operation?

A: It supports both wall and cabinet mounting, offering flexibility to users and ensuring easy integration within different industrial setups.Q: Which communication interfaces are available on the LENZE EVS9325 ES DRIVE?

A: Standard interfaces include RS232, RS485, and CANopen, with Profibus available as an optional upgrade, facilitating seamless connectivity for automation networks.Q: What process is involved in programming the drive?

A: Programming is accomplished using a parameterizable keypad or through PC software (Engineer), allowing users to customize settings to their specific operational requirements.Q: What benefits arise from its self-diagnostics and fault memory features?

A: Comprehensive self-diagnostics and a fault memory enable preventive maintenance and quick troubleshooting, improving uptime and reducing service costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE 33.8202_E

Features : Integrated Safety, Compact Design, Easy Mounting

Cooling Method : Forced Air Cooling

Application : Industrial Automation, Motion Control

Noise Level : <55 dB

Connector Type : Screw Terminal

Storage Temperature : 25C to +70C

LENZE E82EV152 4C000 DRIVE

Features : Compact Design, Integrated Brake Chopper, Modbus Communication

Cooling Method : Forced Air Cooling

Application : Industrial Automation, Motor Control, Conveyor Systems

Noise Level : <65 dB

Connector Type : Screw Terminal

Storage Temperature : 25C to +70C

LENZE SERVO DRIVE EVF9324-EVV004

Features : Integrated EMC Filter, Safe Torque Off, Compact Design, Reliable Operation

Cooling Method : Fan Cooling

Application : Industrial Automation, CNC Machines, Packaging, Robotics

Noise Level : <65 dB

Connector Type : Screw Terminal

Storage Temperature : 25C to +70C

LENZE EVF9324 EV DRIVE

Features : Integrated brake chopper, programmable parameters, LCD display

Cooling Method : Forced air cooling (fan)

Application : Pumps, fans, conveyors, industrial automation

Noise Level : <70 dB(A)

Connector Type : Screw Terminal

Storage Temperature : 25C to +70C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry