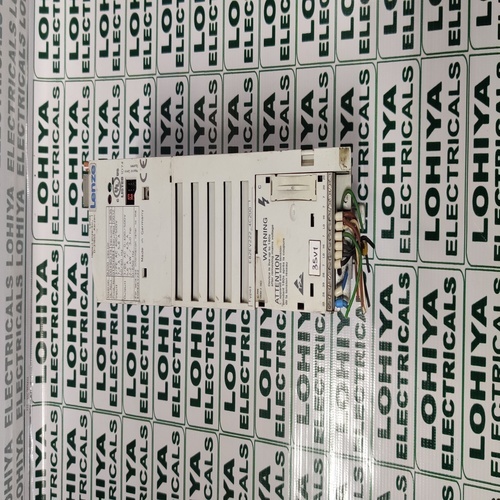

LENZE EVS9322 ETV907 DRIVE

LENZE EVS9322 ETV907 DRIVE Specification

- Phase

- Three Phase

- Output Type

- Three-phase AC

- Rated Current

- 5.5 A

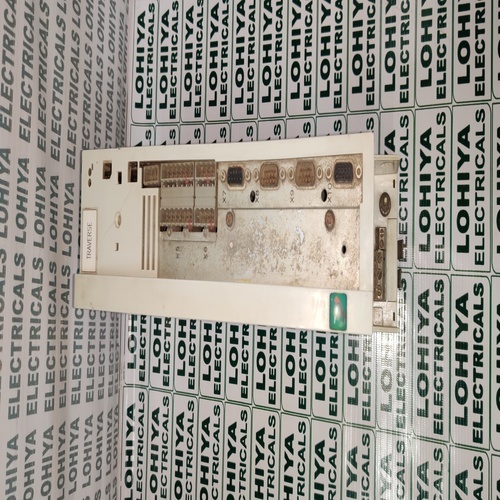

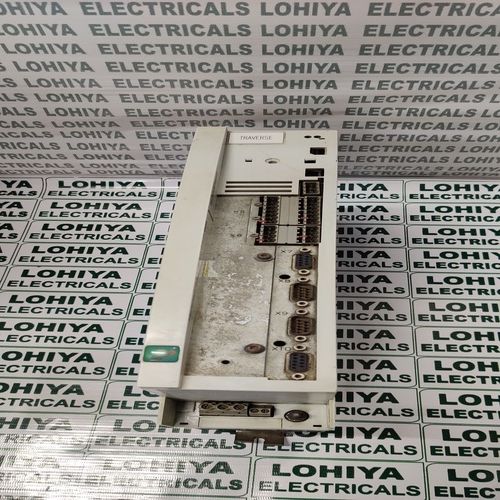

- Connector Type

- Terminal block / plug-in terminals

- Noise Level

- <65 dB(A)

- Working Temperature

- 0C to +55C

- Cooling Method

- Fan-cooled

- Operating Temperature

- 0C to +55C

- Rated Power

- 2.2 kW

- Power Supply

- Three-phase 400 V AC, 50/60 Hz

- Power Factor

- >= 0.95

- Current Range

- up to 6.2 A

- Features

- Integrated brake chopper, Safe Torque Off (STO), modular design, CANopen/Profibus/Digital/Analog I/O

- Output Current

- 5.5 A (rated)

- Application

- Industrial automation, machine tools, conveyor technology, packaging machines

- Product Type

- AC Servo Inverter Drive

- Output Power

- 2.2 kW

- Output Frequency

- 0599 Hz (configurable)

- Input Voltage

- 400 V AC (Three-phase)

- Voltage Protection

- Integrated overvoltage and undervoltage protection

- Efficiency

- up to 98%

- Material

- Industrial grade components with metal enclosure

- Line Regulation

- 0.1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 4.5 kg

About LENZE EVS9322 ETV907 DRIVE

Areas of Application & Competitive Advantages

The LENZE EVS9322 ETV907 DRIVE is tailored for industrial automation, machine tools, conveyor technology, and advanced packaging machines. Its transcendent versatility in plant environments ensures seamless integration into modern manufacturing lines. Key competitive advantages include modular design, exceptional control precision, support for synchronous and asynchronous motors, and robust safety features such as Safe Torque Off (STO). The drives integrated EMC filter, dynamic braking, and superior efficiency set it apart as an indispensable automation asset.

Market Coverage, Packaging & Export Strategy

The main domestic market for the LENZE EVS9322 ETV907 DRIVE spans factories requiring reliable automation. Packaging outlay is minimized using secure, compact materials to protect during transport. Expenditure for quality packaging contributes to a seamless dispatching experience, reducing risks in both local and international shipments. Major export markets include Europe, Asia, and the Middle East, leveraging LENZEs reputation for polished engineering and transcendent product reliability in global automation sectors.

FAQs of LENZE EVS9322 ETV907 DRIVE:

Q: How does the integrated brake chopper enhance usage in dynamic industrial applications?

A: The integrated brake chopper allows for efficient dynamic braking, supporting rapid acceleration and deceleration cycles. This is especially beneficial in automated packaging and conveyor systems where controlled motor stop-start is crucial for productivity and safety.Q: What communication interfaces are available for integrating the LENZE EVS9322 ETV907 DRIVE?

A: The drive offers various communication options including CANopen, Profibus, RS232/RS485, and an optional Ethernet interface, enabling seamless integration with diverse industrial networks and control systems.Q: When should you consider deploying this drive in your automation process?

A: This drive is ideal when your process requires precise control over synchronous or asynchronous motors, robust safety features, and the ability to manage complex input/output configurations for enhanced automation.Q: Where can the LENZE EVS9322 ETV907 DRIVE be mounted within a plant environment?

A: The drive is designed for panel mounting, making it suitable for integration into standard control cabinets located throughout industrial facilities or on the shop floor.Q: What are the main benefits of the modular design in maintenance and system upgrades?

A: The modular construction allows for straightforward servicing, easy component replacement, and flexible future upgrades, reducing downtime and outlay associated with maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE E82EV751K2C

Rated Current : 4.6 A

Material : Industrial Grade Plastic and Metal

Efficiency : Above 95%

Weight : Approx. 2 kg

Connector Type : Screw Terminal

Voltage Protection : Over/Under Voltage Protection

LENZE E82EV222 4C200 DRIVE

Rated Current : 5.5 A

Material : Industrial Grade Plastic/Metal Housing

Efficiency : Above 95%

Weight : Approximately 3.6 kg

Connector Type : Detachable Terminal Block

Voltage Protection : Overvoltage/Undervoltage Protection

LENZE EVF8202-E-V002

Rated Current : 2A

Material : Metal casing

Efficiency : High efficiency

Weight : Approx. 1.5kg

Connector Type : Screw terminal connectors

Voltage Protection : Overvoltage and undervoltage protection

LENZE EVF8201-E

Rated Current : 1.2 A

Material : Highgrade plastic and metal

Efficiency : High

Weight : 0.6 kg

Connector Type : Screw Terminal

Voltage Protection : Overvoltage and Undervoltage Protection

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry